Product Overview

Low Voltage Reeling Cable is engineered for demanding movable equipment applications requiring exceptional flexibility and durability. Designed for port machinery, container cranes, lifts, and mining equipment, this cable withstands continuous mechanical stress while providing reliable power transmission in harsh environmental conditions.

Key Features & Benefits

-

Extended Temperature Range: Continuous operation at 90°C with capability to withstand -35°C outdoor conditions

-

Superior Environmental Resistance: Ozone resistant, UV resistant, and humidity resistant properties

-

Enhanced Mechanical Strength: Kevlar braided reinforcement layer provides exceptional tensile strength

-

Oil Resistant Performance: Suitable for applications where oil exposure is common

-

Flexible Construction: EPR insulation with PUR sheath ensures excellent flexibility for reeling applications

-

High Load Capacity: Maximum tensile loads from 3500N to 13000N depending on cable size

Applications

Movable equipment and machinery applications:

-

Port Container Cranes: Power supply for movable container handling equipment

-

Industrial Lifts: Elevating and lifting equipment power transmission

-

Mining Equipment: Ground and well-bottom machinery with mechanical stress

-

Grab Dredgers: Dredging equipment and marine applications

-

Movable Heavy Equipment: Large mobile machinery requiring flexible power supply

-

Outdoor Applications: Equipment exposed to weather conditions

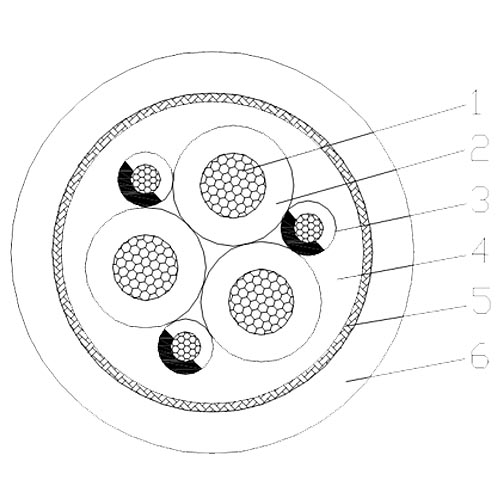

Construction

Robust Multi-Layer Construction:

-

Copper Conductor

-

Insulation

-

Ground Core

-

Inner Sheath

-

Kevlar Braided Reinforce Layer

-

Outer Sheath

Code Design

Cable Identification System:

-

G: Cable for Port machinery

-

E: EPR Insulation

-

U: PUR Sheath

-

R: Flexible Conductors

Cable Specifications

Detailed Technical Specifications:

| Cross Section | Conductor Construction | Maximum Outer Diameter | Approximate Weight | Maximum Load |

|---|---|---|---|---|

| mm² | (tinned copper) | mm | kg/km | N |

| 3×25+3×6 | 3×196/0.40+3×84/0.30 | 32 | 1500 | 3500 |

| 3×35+3×6 | 3×276/0.40+3×84/0.30 | 35 | 1950 | 4000 |

| 3×50+3×10 | 3×396/0.40+3×84/0.40 | 39 | 2590 | 4500 |

| 3×70+3×16 | 3×380/0.49+3×126/0.40 | 45 | 3720 | 5500 |

| 3×95+3×16 | 3×513/0.49+3×126/0.40 | 51 | 4450 | 6500 |

| 3×120+3×16 | 3×630/0.49+3×126/0.40 | 56 | 5600 | 7500 |

| 3×150+3×25 | 3×777/0.49+3×196/0.40 | 61 | 7000 | 9500 |

| 3×185+3×35 | 3×976/0.49+3×276/0.40 | 67 | 8400 | 12000 |

| 3×240+3×50 | 3×1281/0.49+3×396/0.40 | 74 | 11150 | 13000 |

Key Advantages

-

Proven Durability: Specifically designed for continuous reeling applications in demanding environments

-

Weather Resistance: Performs reliably in outdoor conditions with UV, ozone, and humidity protection

-

High Temperature Performance: Maintains integrity at continuous 90°C operation

-

Superior Mechanical Protection: Kevlar reinforcement provides exceptional tensile strength

-

Comprehensive Size Range: Available from 25mm² to 240mm² to suit various power requirements

-

Oil Resistant Construction: Suitable for industrial environments where oil exposure occurs

-

Color Coding: Standard black cores and sheaths for easy identification and professional appearance