Product Overview

This high flexible energy chain control cable is specifically engineered for energy chain control systems in port equipment. Designed for high-speed applications with significant acceleration capabilities, the cable meets demanding requirements for UV resistance, flame resistance, halogen-free operation, and extreme temperature performance.

Key Applications

-

Energy chain control systems of port equipment

-

High-speed and high-acceleration machinery

-

Automated equipment requiring torsion capability

-

UV-exposed industrial environments

-

Applications demanding halogen-free cables

Technical Specifications

-

Rated Voltage: 300/500V

-

Temperature Range: -35°C to +100°C

-

Minimum Bending Radius: 6× cable diameter (D)

-

Environmental Resistance: High abrasion, ozone, oil, UV, and moisture resistant

-

Flame Retardant: Yes

-

Halogen Free: Yes

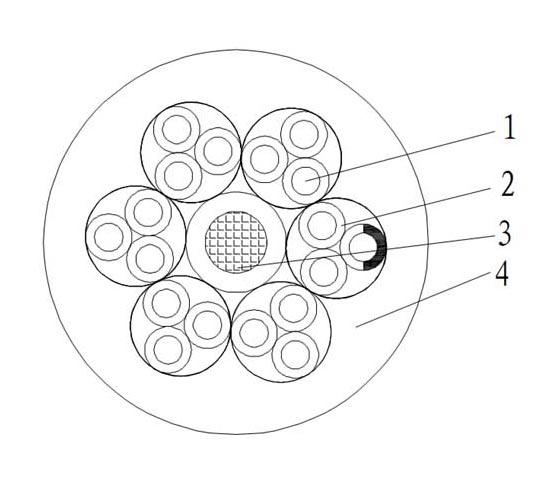

Cable Construction

-

Conductor: Fine stranded copper wire

-

Insulation: TPEE Compound

-

Reinforcement: Nylon Reinforced Core

-

Sheath: TPU (PUR mixture)

Color Coding: Cores are black with white consecutive numbering; includes green/yellow earth core; sheath is black

Product Code System

-

G: Cable for Port machinery / Reinforced

-

K: For control systems

-

U: PUR Sheath

-

R: Flexible Conductors

Technical Specifications Table

| Cross Section (mm²) | Conductor Construction | Nom. OD of Cable (mm) | Max. OD of Cable (mm) | Approx Weight (kg/km) |

|---|---|---|---|---|

| 4×0.75 | 4×24/0.20 | 7.1 | 7.8 | 70 |

| 6×0.75 | 6×24/0.20 | 9.3 | 10.2 | 101 |

| 8×0.75 | 8×24/0.20 | 9.9 | 10.9 | 126 |

| 12×0.75 | 12×24/0.20 | 12.6 | 13.9 | 185 |

| 18×0.75 | 18×24/0.20 | 14.8 | 16.3 | 259 |

| 20×0.75 | 20×24/0.20 | 15.4 | 16.9 | 288 |

| 25×0.75 | 25×24/0.20 | 16.4 | 18.0 | 352 |

| 4×1 | 4×32/0.20 | 7.5 | 8.2 | 83 |

| 6×1 | 6×32/0.20 | 9.9 | 10.8 | 121 |

| 8×1 | 8×32/0.20 | 10.6 | 11.6 | 151 |

| 12×1 | 12×32/0.20 | 13.5 | 14.9 | 223 |

| 18×1 | 18×32/0.20 | 15.9 | 17.5 | 315 |

| 20×1 | 20×32/0.20 | 16.5 | 18.1 | 350 |

| 25×1 | 25×32/0.20 | 17.5 | 19.3 | 428 |

| 4×1.5 | 4×48/0.20 | 8.2 | 9.0 | 109 |

| 6×1.5 | 6×48/0.20 | 10.9 | 12.0 | 161 |

| 8×1.5 | 8×48/0.20 | 11.8 | 12.9 | 203 |

| 12×1.5 | 12×48/0.20 | 15.1 | 16.6 | 300 |

| 18×1.5 | 18×48/0.20 | 18.2 | 20.0 | 442 |

| 20×1.5 | 20×48/0.20 | 19.0 | 20.9 | 498 |

| 25×1.5 | 25×48/0.20 | 20.4 | 22.5 | 616 |

| 4×2.5 | 4×77/0.20 | 9.6 | 10.6 | 160 |

| 6×2.5 | 6×77/0.20 | 13.1 | 14.4 | 237 |

| 8×2.5 | 8×77/0.20 | 14.1 | 15.5 | 302 |

| 12×2.5 | 12×77/0.20 | 18.2 | 20.0 | 448 |

| 18×2.5 | 18×77/0.20 | 22.6 | 25.3 | 690 |

| 20×2.5 | 20×77/0.20 | 23.4 | 25.7 | 763 |

| 25×2.5 | 25×77/0.20 | 24.8 | 27.3 | 933 |

Features & Benefits

-

High Flexibility: Specifically designed for energy chain applications with torsion capability

-

Extreme Temperature Range: Operates from -35°C to +100°C

-

Premium Materials: TPEE insulation and PUR sheath for superior performance

-

Environmental Protection: Comprehensive resistance to abrasion, ozone, oil, UV, and moisture

-

Flame Retardant & Halogen Free: Enhanced safety for industrial environments

-

Multiple Configurations: Available from 4 to 25 cores in various cross-sections

-

High-Speed Capable: Suitable for applications with significant accelerations

Performance Characteristics

-

Capable of torsion according to type

-

Suitable for high speeds and accelerations

-

UV-resistant for outdoor applications

-

Flame resistant and halogen free

-

Excellent performance at high and very low temperatures

Note: All technical specifications are based on standard manufacturing conditions. Consult our engineering team for specific application requirements and custom solutions.