Product Overview

Medium Voltage High Stress Reeling Cable is engineered for demanding mobile equipment applications requiring exceptional mechanical durability and medium voltage performance. Specifically designed for container cranes, lifting equipment, mining shearers, and excavators, this cable withstands high mechanical stress while maintaining reliable power transmission in the most challenging industrial environments.

Key Features & Benefits

-

Superior Mechanical Durability: Withstands high tensile and torsional stresses common to cable reeling applications

-

Compact Design: Smaller outer diameter than traditional rubber cables saves space and reduces weight

-

Reinforced Construction: Central bearing reinforced core diffuses tension and prevents spiral effect

-

Environmental Resistance: Flame, abrasion, chemical, moisture, impact, and tear resistant

-

Halogen-Free Safety: PCP outer sheath ensures safety in case of fire

-

High Load Capacity: Maximum tensile loads from 1500N to 7200N depending on configuration

Applications

Demanding mobile equipment applications:

-

Container Handling Cranes: Power supply for container loading/unloading operations

-

Lifting Equipment: Heavy-duty lifting and material handling systems

-

Mining Equipment: Shearer machines and excavators in mining operations

-

Stacker Reclaimers: Bulk material handling equipment

-

Ship Loaders/Unloaders: Port and shipping terminal equipment

-

High Travel Speed Applications: Equipment requiring rapid cable movement

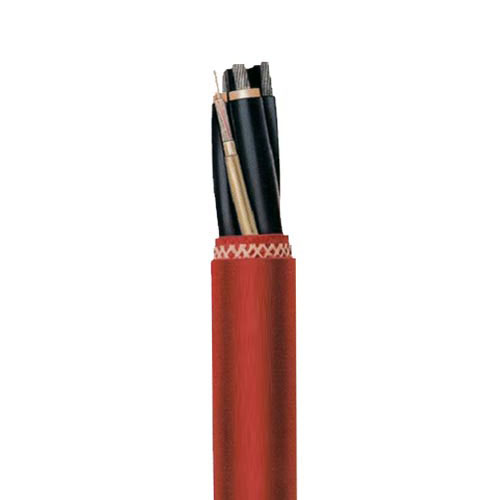

Construction

Robust Multi-Layer Construction:

-

Conductor: Stranded bare copper wire

-

Insulation: Ethylene-propylene rubber (EPR) insulation

-

Reinforcement: Center support member

-

Option: Fiber optic core available

-

Braid: Steel wire/Copper wire braided layer

-

Outer Sheath: Halogen-free PCP composition

Specifications

3.6/6KV Specifications:

| Cross Section | Conductor Construction | Maximum Outer Diameter | Weight | Maximum Load |

|---|---|---|---|---|

| mm² | (tinned copper) | mm | kg/km | N |

| 3×25+3×8 | 3×196/0.40+3×112×0.30 | 46.9 | 3007 | 1500 |

| 3×35+3×8 | 3×276/0.40+3×112/0.30 | 50.9 | 3621 | 2100 |

| 3×50+3×8 | 3×396/0.40+3×112/0.30 | 55.6 | 4502 | 3000 |

| 3×70+3×12 | 3×380/0.49+3×168/0.30 | 59.5 | 5563 | 4200 |

| 3×95+3×16 | 3×513/0.49+3×126/0.40 | 65.5 | 6988 | 5700 |

| 3×120+3×25 | 3×630/0.49+3×196/0.40 | 69.0 | 8160 | 7200 |

6/10KV Specifications:

| Cross Section | Conductor Construction | Maximum Outer Diameter | Weight | Maximum Load |

|---|---|---|---|---|

| mm² | (tinned copper) | mm | kg/km | N |

| 3×25+3×8 | 3×196/0.40+3×112×0.30 | 52.5 | 3609 | 1500 |

| 3×35+3×8 | 3×276/0.40+3×112/0.30 | 56.5 | 4273 | 2100 |

| 3×50+3×8 | 3×396/0.40+3×112/0.30 | 61.5 | 5215 | 3000 |

| 3×75+3×12 | 3×380/0.49+3×168/0.30 | 65.0 | 6323 | 4200 |

| 3×95+3×16 | 3×513/0.49+3×126/0.40 | 71.0 | 7824 | 5700 |

| 3×120+3×25 | 3×630/0.49+3×196/0.40 | 74.5 | 9038 | 7200 |

Key Advantages

-

Proven Reliability: Specifically designed for high-stress reeling applications with continuous operation

-

Cost Efficiency: Compact design reduces guide wheel and drive motor requirements

-

Spiral Effect Prevention: Reinforced core design prevents cable distortion during reeling operations

-

Temperature Extreme Performance: Maintains integrity in both high and low temperature environments

-

Multiple Voltage Ratings: Available in 3.6/6KV and 6/10KV configurations for various applications

-

Comprehensive Protection: Braided layer provides additional mechanical protection against impact and abrasion

-

Flexible Configuration: Optional fiber optic core allows for integrated data transmission