Product Overview

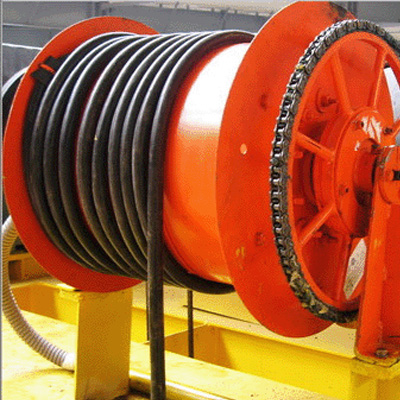

Engineered for extreme industrial reel applications, this steel wire reinforced silicone rubber cable withstands continuous 180°C temperatures, high torsion, and mechanical stress. Featuring tinned copper conductors and specialized construction, it delivers reliable power and control signal transmission for crane systems, hoists, and mobile equipment in demanding environments.

Key Features & Benefits

-

180°C Continuous Operation: +220°C short-term peak performance

-

Mechanical Durability: Steel wire reinforcement resists tensile forces up to 15 kN

-

Torsion Resistance: Handles ±180°/meter twist during operation

-

Flexible in Extreme Temperatures: -60°C to +220°C operational range

-

Dual Variants: Tensile (J-type) & EMI-Shielded (P-type) configurations

-

Chemical Resilience: Resists oils, acids, and industrial solvents

Construction

| Layer | J-Type (Tensile) | P-Type (Shielded) |

|---|---|---|

| Conductor | Tinned Copper Strands (Class 6) | Tinned Copper Strands (Class 6) |

| Insulation | Silicone Rubber | Silicone Rubber |

| Inner Sheath | Braided Silicone Reinforcement | Braided Silicone Reinforcement |

| Reinforcement | Galvanized Steel Wire | - |

| Shielding | - | Tinned Copper + Nylon Composite |

| Outer Sheath | High-Strength Silicone (Red/Black) | High-Strength Silicone (Red/Black) |

Technical Data

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1kV Power · 300/500V Control |

| Temperature Range | Continuous: -60°C to +180°C Peak: +220°C (≤30min) |

| Torsion Resistance | ±180°/meter |

| Min. Bending Radius | 8 × OD (Static) · 10 × OD (Dynamic) |

| Tensile Strength | ≥15 kN (J-Type) |

| EMI Protection | 85 dB attenuation (P-Type) |

| Standards Compliance | IEC 60228, IEC 60502-1, DIN VDE 0250 |

Applications

-

Port Equipment: STS cranes, RMG systems, ship unloaders

-

Mining Machinery: Stackers, reclaimers, underground mining equipment

-

Material Handling: Hoists, winches, spring-controlled reels

-

Industrial Processing: Steel mills, glass factories, cement plants

-

Mobile Systems: Automated guided vehicles (AGVs), telescopic handlers

Engineering Selection Guide

-

Cable Type Selection

-

J-Type: For applications requiring tensile strength (cranes, hoists)

-

P-Type: For EMI-sensitive systems (control signals, VFD feeds)

-

-

Installation Requirements

-

Maintain minimum bend radii during winding

-

Use torsion-resistant cable glands

-

Allow free movement in reel troughs

-

3. Environmental Limits

-

-

-

Avoid UV exposure beyond 6 months

-

Chemical splash requires immediate cleaning

-

-

Standards Compliance

| Standard | Scope |

|---|---|

| IEC 60502-1 | Power cables up to 1kV |

| IEC 60228 | Conductors (Class 6 flexibility) |

| DIN VDE 0250 | German cable construction standards |

| ISO 6722 | Road vehicle cable specifications |