Product Overview

Festoon System Power and Control Cable is engineered for energy and control applications in festoon systems operating under severe conditions with frequent bending cycles. Featuring EPR insulation and CR sheathing, this cable delivers exceptional durability for demanding applications including drag lines, machine tools, and materials handling systems.

Applications

-

Festoon systems under severe conditions

-

Drag lines and crane applications

-

Machine tools and automation systems

-

Materials handling equipment

-

Industrial machinery with frequent bending

-

Port machinery and heavy equipment

Cable Performance

-

Rated Voltage: Uo/U 0.6/1 kV

-

Temperature Range: -35°C to +90°C

-

Minimum Bending Radius: 6 × Cable Diameter

-

Key Features: High abrasion resistance, ozone resistance, oil resistance, flame retardant, UV radiation resistance, moisture resistance

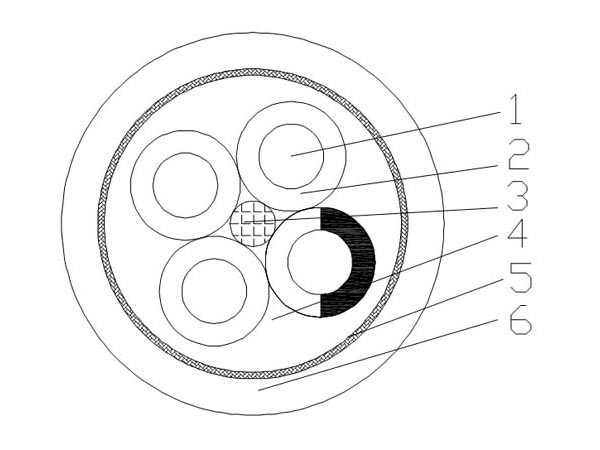

Construction Details

-

Conductor - Flexible copper conductors

-

Insulation - EPR rubber mixtures

-

Nylon Reinforced Core - Enhanced mechanical strength

-

Inner Sheath - CR rubber mixtures (except single-core cables)

-

Braid Reinforced Layer - Aramid fiber reinforcement

-

Outer Sheath - CR rubber mixtures, black color

Code Design

| Component | Code | Description |

|---|---|---|

| Application | G | Cable for Port machinery |

| Application | YD | Cable for festoon systems |

| Insulation | E | EPR Insulation |

| Sheath | F | CR Sheath |

| Conductor | R | Flexible Conductors |

| Reinforcement | J | Aramid fiber reinforced |

Festoon Power Cable Specifications

Single Core Power Cable

| Cross Section (mm²) | Construction | Nominal OD (mm) | Max OD (mm) | Weight (kg/km) | Max Strength (N) |

|---|---|---|---|---|---|

| 1×10 | 1×322/0.20 | 11.6 | 12.8 | 205 | 200 |

| 1×16 | 1×513/0.20 | 13.0 | 14.3 | 280 | 250 |

| 1×25 | 1×798/0.20 | 14.8 | 16.3 | 399 | 375 |

| 1×35 | 1×1121/0.20 | 16.2 | 17.8 | 514 | 525 |

| 1×50 | 1×703/0.30 | 18.4 | 20.2 | 693 | 750 |

| 1×70 | 1×999/0.30 | 21.1 | 22.8 | 948 | 1050 |

| 1×95 | 1×1332/0.30 | 22.9 | 24.7 | 1198 | 1425 |

| 1×120 | 1×1702/0.30 | 24.7 | 26.7 | 1505 | 1800 |

| 1×150 | 1×2109/0.30 | 27.1 | 29.3 | 1835 | 2250 |

| 1×185 | 1×1443/0.40 | 29.7 | 32.1 | 2206 | 2775 |

Multi-Core Power Cable

| Cross Section (mm²) | Construction | Nominal OD (mm) | Max OD (mm) | Weight (kg/km) | Max Strength (N) |

|---|---|---|---|---|---|

| 4×4 | 4×126/0.20 | 20.1 | 22.2 | 439 | 240 |

| 4×6 | 4×189/0.20 | 22.6 | 24.9 | 559 | 360 |

| 4×10 | 4×322/0.20 | 26.3 | 28.4 | 805 | 600 |

| 4×16 | 4×513/0.20 | 29.4 | 31.7 | 1072 | 960 |

| 4×25 | 4×798/0.20 | 33.7 | 36.4 | 1535 | 1500 |

| 4×35 | 4×1121/0.20 | 35.9 | 38.5 | 2290 | 2100 |

Festoon Control Cable Specifications

1.5mm² Control Cable

| Core Configuration | Construction | Nominal OD (mm) | Max OD (mm) | Weight (kg/km) | Max Strength (N) |

|---|---|---|---|---|---|

| 12×1.5 | 12×48/0.20 | 21.8 | 24.0 | 593 | 270 |

| 18×1.5 | 18×48/0.20 | 24.5 | 27.0 | 789 | 405 |

| 24×1.5 | 24×48/0.20 | 28.5 | 31.4 | 1048 | 540 |

| 30×1.5 | 30×48/0.20 | 29.8 | 32.8 | 1223 | 675 |

| 36×1.5 | 36×48/0.20 | 32.7 | 36.0 | 1486 | 810 |

2.5mm² Control Cable

| Core Configuration | Construction | Nominal OD (mm) | Max OD (mm) | Weight (kg/km) | Max Strength (N) |

|---|---|---|---|---|---|

| 7×2.5 | 7×77/0.20 | 20.7 | 22.8 | 512 | 262 |

| 12×2.5 | 12×77/0.20 | 23.9 | 26.3 | 736 | 450 |

| 18×2.5 | 18×77/0.20 | 27.0 | 29.7 | 993 | 650 |

| 24×2.5 | 24×77/0.20 | 31.5 | 34.7 | 1319 | 900 |

| 30×2.5 | 30×77/0.20 | 33.0 | 36.3 | 1551 | 1125 |

| 36×2.5 | 36×77/0.20 | 36.2 | 39.8 | 1881 | 1350 |

Additional Features

-

Core Identification: Black cores with white numbering, includes green/yellow earth core

-

Sheath Color: Standard black outer sheath

-

Flexible Design: Optimized for frequent bending applications

-

Robust Construction: Multiple reinforcement layers for extended service life