Product Overview

The SiHF FRNC Silicone Multicore Heat Resistant Cable is engineered for extreme environmental resilience. Designed to operate reliably under continuous high temperatures, severe cold, chemical exposure, and mechanical stress, this cable delivers exceptional electrical stability and longevity in demanding industrial applications. Its flame-retardant, non-corrosive (FRNC) properties enhance safety in critical installations.

Key Features & Advantages

-

Extended Temperature Range: Continuous operation from -60°C to +180°C.

-

Superior Environmental Resistance: Excellent performance against heat radiation, cold, acids, alkalis, corrosive gases, oils, and moisture/water.

-

Enhanced Flame Safety: FRNC (Flame Retardant, Non-Corrosive): Self-extinguishing properties with low smoke and non-corrosive gas emission when exposed to fire.

-

Exceptional Flexibility & Durability: Highly flexible silicone rubber construction simplifies installation in confined spaces and resists cutting, tearing, and mechanical damage. Eliminates the need for steel wire armor.

-

Stable Electrical Performance: Maintains reliable insulation and conductivity even under extreme thermal cycling (high heat and deep cold).

-

Outstanding Longevity: Superior resistance to aging ensures a significantly longer service life compared to standard silicone or PVC cables in harsh conditions.

-

Post-Fire Integrity: Forms a protective silica ash layer upon burning, maintaining residual insulation properties.

Technical Specifications

-

Conductor: Finely stranded bare or tinned copper (according to specific order).

-

Insulation: High-grade Silicone Rubber (SiR).

-

Sheath/Jacket: Flame Retardant, Non-Corrosive (FRNC) Silicone Rubber Compound.

-

Core Configuration: Multicore (2, 3, 4, 5+ cores available - specify required configuration).

-

Voltage Rating: Typically 600V AC/DC (Confirm specific standards like UL, IEC, etc., as required).

-

Temperature Rating:

-

Continuous Operation: -60°C to +180°C

-

Short Circuit: +250°C (max 5 sec duration - confirm per standard)

-

-

Bending Radius: Minimum 6 x Overall Cable Diameter (enables flexible routing).

-

Standards Compliance: Manufactured to meet relevant international standards (e.g., IEC 60245, UL 62, CSA, or specific customer specifications - specify applicable standards based on target market).

-

Flame Performance: FRNC - Passes standard flame retardancy tests (e.g., IEC 60332-1) with low acid gas/corrosivity emission.

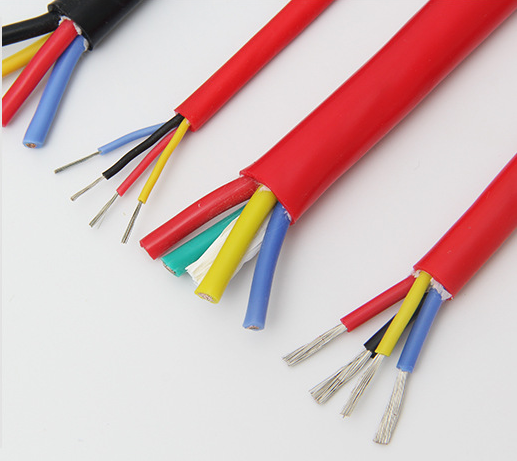

Cable Construction

-

Conductor: Multiple strands of high-purity copper (bare or tinned for enhanced solderability/corrosion resistance).

-

Insulation: A layer of heat-resistant silicone rubber (SiR) individually extruded over each conductor, providing primary electrical insulation and thermal stability.

-

Filler (Optional): Non-hygroscopic fillers may be used in multicore constructions to maintain core arrangement and circularity.

-

Inner Sheath (Optional): May include a binder tape or inner bedding layer depending on core count and construction.

-

Overall Sheath/Jacket: A robust, seamless extrusion of specially formulated FRNC Silicone Rubber compound. This outer layer provides mechanical protection, environmental sealing (water, oil, chemicals), UV resistance, and the critical flame-retardant, non-corrosive properties.

Material Characteristics (Silicone Rubber)

-

Thermal Stability: Maintains flexibility and insulation properties across the wide operating temperature range.

-

Oxidation & Ozone Resistance: Highly resistant to degradation from heat aging and atmospheric ozone.

-

Chemical Resistance: Withstands exposure to a wide range of chemicals, solvents, oils, and corrosive agents.

-

Hydrophobicity: Naturally water-repellent, enhancing moisture resistance.

-

High Flexibility: Remains pliable even at low temperatures, easing installation and handling.

-

Tear & Abrasion Resistant: The specialized compound offers improved mechanical robustness.

Application Scenarios

Ideal for power supply and control wiring in high-temperature or harsh industrial environments, including:

-

Power Generation: Internal wiring in generators, turbines, boilers, and near heat sources in power plants.

-

Metallurgy: Steel mills, foundries, furnaces, rolling mills, and metal processing equipment.

-

Chemical & Petrochemical: Plants, refineries, reactors, and areas with corrosive vapors or chemical splashes.

-

Industrial Machinery: Welding equipment, glass manufacturing, ceramics kilns, ovens, dryers, and heating systems.

-

Mobile Equipment: Power connections for heavy machinery, cranes, and equipment requiring high flexibility and temperature resistance.

-

Any Application requiring reliable, flexible power transmission under continuous high heat, extreme cold, or exposure to chemicals/oils/moisture.

Engineering Selection Notes

-

Select based on required core count, conductor size (AWG/mm²), voltage rating, and specific environmental hazards.

-

Verify compliance with local and industry-specific safety standards (e.g., NEC, IEC, ATEX for hazardous areas if applicable).

-

The inherent flexibility and FRNC jacket make it suitable for fixed installations and applications requiring frequent movement or bending in tight spaces.

-

Its long lifespan under harsh conditions offers a lower total cost of ownership compared to less durable alternatives.