Product Overview

The SiHF EWKF Silicone Multicore Heat-Resistant Cable is engineered for extreme industrial environments demanding exceptional mechanical durability, temperature resilience (-60°C to +200°C), and flexibility. Featuring proprietary EWKF silicone technology (Enhanced Tear/Cut Resistance + Softness), this cable eliminates the need for steel wire armor while outperforming traditional silicone cables in lifespan and reliability. Ideal for automation systems, machinery, and mobile equipment in high-stress sectors like steel, aviation, and heavy manufacturing.

Key Advantages vs. Standard Silicone Cables

50%+ Longer Service Life in abrasive/corrosive environments

Zero Steel Armor Required – 40% lighter & superior flexibility

Maintains Insulation After Combustion (SiO₂ ash layer)

Resists Mechanical Damage: Cutting, tearing, crushing

Simplified Installation in confined spaces due to high flexibility

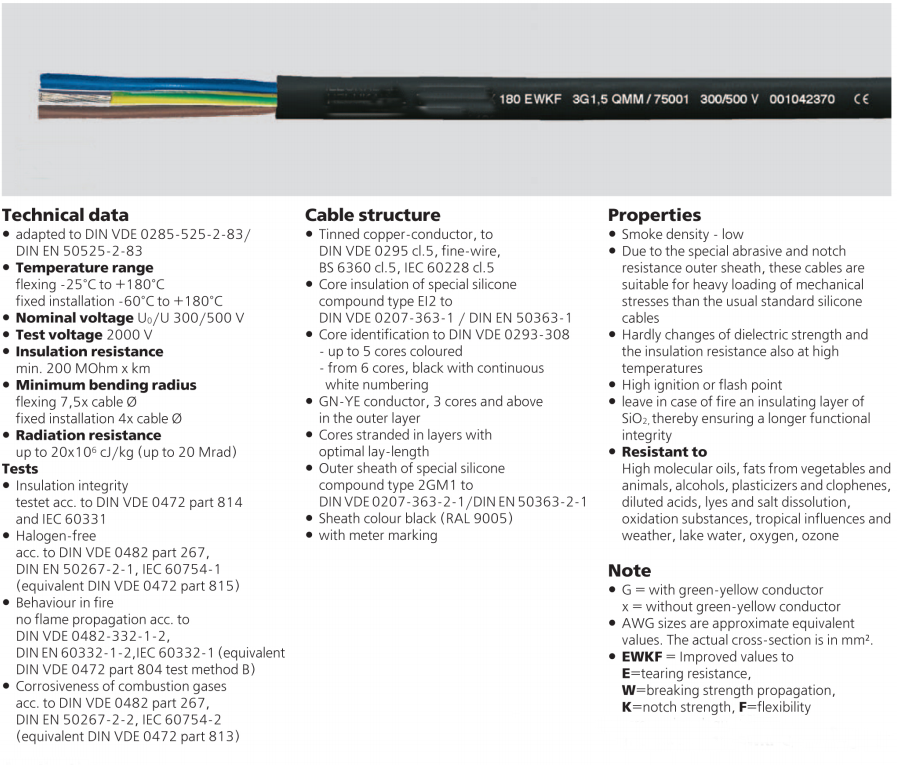

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 300/500V (Typical, per IEC 60245) |

| Temp. Range | -60°C to +200°C (Continuous) |

| Conductor | Stranded Tinned Copper (Fine Wire) |

| Insulation/Sheath | EWKF Silicone Rubber (Proprietary) |

| Flame Performance | Halogen-Free, IEC 60332-1-2 Compliant |

| Shielding | Optional (Recommended for EMI Environments) |

| Bending Radius | ≥ 5x Cable OD (Non-Armored Design) |

| Standards | IEC 60245, IEC 60332-1-2, RoHS |

EWKF Material Code Breakdown

| Code | Property | Technical Benefit |

|---|---|---|

| E | Initial Tear Resistance | Prevents damage during installation |

| W | Tear Propagation Resistance | Limits crack spread under stress |

| K | Cut Resistance | Withstands abrasion & sharp impacts |

| F | Softness | Enables tight bends in cable carriers/tracks |

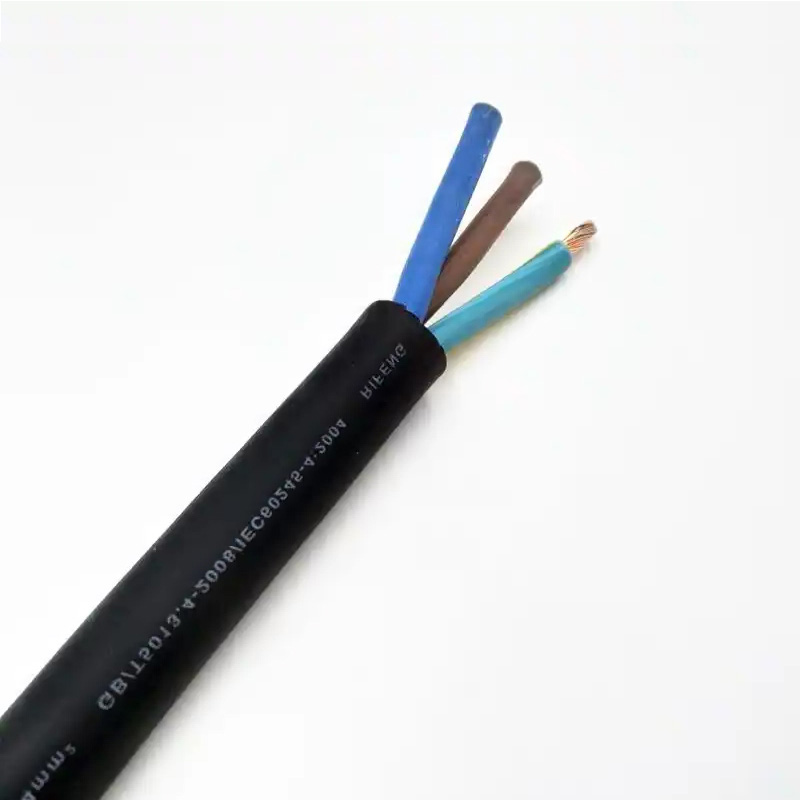

Construction Details

-

Conductor: Fine-stranded tinned copper (enhanced corrosion resistance)

-

Insulation: EWKF Silicone Rubber per core (optimized dielectric + mechanical protection)

-

Cabling: Stranded cores with fillers for roundness

-

Sheath: EWKF Silicone Rubber outer layer (black)

-

Thickness: Customizable based on core count/size

-

Tear strength: ≥ 15 N/mm (per proprietary compound)

-

Unique Material Properties

-

Combustion Safety: Forms insulating SiO₂ ash layer during fire (maintains circuit integrity)

-

Chemical Resistance: Oils, greases, alcohols, animal/plant fats, acids, alkalis

-

Environmental Resilience: UV resistance, hydrolysis resistance, ozone resistance

-

Mechanical Strength: 3x higher tear/cut resistance vs. standard silicone

Target Applications

-

Industrial Automation: Robotic arms, CNC machines, assembly lines

-

Heavy Industry: Steel mills, cement plants, glass furnaces, shipyards

-

Material Handling: Logistics conveyors, sorting systems, automated warehouses

-

Mobile Machinery: Non-continuous reciprocating motion (no forced traction)

-

EMI-Sensitive Areas: Use shielded version for VFDs, servo motors (SiHF EWKF-P)

Industry-Specific Use Cases

| Sector | Application | Benefit Realized |

|---|---|---|

| Steel/Metallurgy | Ladle crane controls, furnace wiring | Resists molten splatter + mechanical abuse |

| Aviation | Hangar equipment, test rigs | Withstands fuel/oil + extreme temps |

| Cement/Glass | Kiln controls, conveyor systems | Immune to dust abrasion + high heat |

| Shipbuilding | Welding equipment, dock machinery | Saltwater corrosion resistance |

Ordering Information

Specify:

-

Core Count (e.g., 4, 8, 12)

-

Conductor Size (mm²)

-

Length

-

Shielding Requirement:

-

Unshielded: SiHF EWKF

-

Shielded: SiHF EWKF-P (tinned copper braid ≥85% coverage)

-

-

Customization: Core colors, OD tolerance (±0.1mm), certifications