Product Overview

H01N2D and H01N2E (NSKFFÖU) Welding Cables are engineered for demanding welding applications requiring exceptional flexibility, oil resistance, and durability. Designed for both mobile and fixed installations under harsh conditions, these cables withstand exposure to inert gas, ozone, light, and various chemicals while delivering reliable performance in automotive, shipbuilding, and industrial welding operations.

Key Features & Benefits

-

Superior Oil & Chemical Resistance: Withstands exposure to oils, acids, fats, and petrols

-

Exceptional Flexibility: Class 6 stranded copper conductors ensure maximum flexibility for easy handling

-

Wide Temperature Range: Suitable for mobile installations from -25°C to +80°C and fixed installations from -40°C to +90°C

-

Environmental Durability: Resistant to UV radiation, ozone, and various environmental challenges

-

Enhanced Safety: Flame retardant, cold-resistant, and free from hazardous substances (RoHS compliant)

-

Optimized Bending Radius: 12× cable outer diameter for easy installation in confined spaces

Applications

Comprehensive welding and industrial applications:

-

Welding Tools & Equipment: Connections between welding devices and tools

-

Automotive Industry: Welding robot connections in automotive manufacturing

-

Shipbuilding Applications: Manual and automated welding in shipyards

-

Assembly Lines: Manual or automated assembly line and spot welding installations

-

Mobile Installations: Applications requiring movement under harsh conditions

-

Outdoor & Indoor Use: Suitable for wet, dry rooms, and outdoor installations

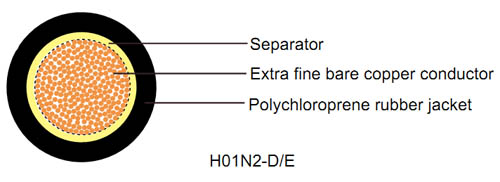

Construction

Optimized Construction for Welding Applications:

-

Conductor: Complies with VDE0295/IEC228 Category 6 stranded copper wire

-

Insulation: Neoprene composite insulation (customized colors available)

Performance Specifications

Electrical & Mechanical Performance:

-

Operating Voltage: 100V

-

Insulation Resistance: >20 MΩ·km

-

Minimum Bend Radius: 12 × Cable Outer Diameter

Temperature Ratings:

-

Mobile Installation: -25°C to +80°C

-

Fixed Installation: -40°C to +90°C

Technical Data

Detailed Technical Specifications:

| Conductor Cross Section (mm²) | Outer Diameter (mm) | 20°C DC Resistance (Ω/km) | Current (Amp) | |

|---|---|---|---|---|

| Min | Max | |||

| 10 | 7.8 | 10.0 | 1.91 | 110 |

| 16 | 9.0 | 11.5 | 1.21 | 138 |

| 25 | 10.0 | 13.0 | 0.78 | 187 |

| 35 | 11.5 | 14.5 | 0.554 | 233 |

| 50 | 13.0 | 17.0 | 0.386 | 295 |

| 70 | 15.0 | 19.0 | 0.272 | 372 |

| 95 | 17.5 | 21.5 | 0.206 | 449 |

| 120 | 19.5 | 24.0 | 0.161 | 523 |

| 150 | 21.5 | 26.0 | 0.129 | 608 |

| 185 | 22.0 | 29.0 | 0.106 | 290 |

Certifications & Compliance

Standards & Directives:

-

Product Compliance: EEC directive 73/23 (Low Voltage Directive) CE regulations

-

Environmental Compliance: RoHS compliant, no hazardous substances

-

Quality Standards: Complies with CE, TUV, VDE and other international standards

Key Advantages

-

Proven Reliability: Robust cable structure resistant to low and high temperatures, ozone and radiation

-

Enhanced Safety Features: Flame retardant and free from hazardous materials

-

Superior Chemical Resistance: Withstands oils, acids, fats, and petrols in industrial environments

-

Optimal Flexibility: Category 6 stranding ensures excellent flexibility for welding applications

-

Comprehensive Certification: Meets European and international standards for quality and safety

-

Wide Application Range: Suitable for both manual operations and automated welding systems