Product Overview

NTSCGECWOEU High Voltage Monitor Screened Trailing Cable is engineered for critical high-voltage applications in mining and tunneling environments where both electrical safety and mechanical durability are paramount. Featuring an advanced monitoring shield system and exceptional flexibility, this cable enables safe operation of mobile high-voltage equipment while providing continuous insulation monitoring for enhanced operational safety.

Key Features & Benefits

-

Advanced Monitoring System: Phase-concentric earth conductor and common-concentric monitoring shield enable real-time insulation fault detection

-

High Voltage Capability: Rated for 6/10kV and 12/20kV applications in demanding mining environments

-

Exceptional Mechanical Durability: Withstands high mechanical loads while maintaining flexibility for mobile equipment

-

Continuous Operation Capability: Allows equipment to be moved while running without interrupting power supply

-

Enhanced Safety Compliance: Integrated monitoring system works with high-voltage protection circuits for maximum safety

-

Robust Construction: Multiple protective layers ensure reliability in hazardous mining environments

Applications

Critical high-voltage applications in mining and underground operations:

-

High-Voltage Transformers: Power lines in underground mining and tunneling operations

-

Mobile Electrical Equipment: Connection of equipment requiring movement during operation

-

Underground Excavations: Hazardous environments with high mechanical stress requirements

-

Mining Power Distribution: High-voltage power transmission in mining applications

-

Tunneling Operations: Equipment connections in tunnel construction and development

-

High-Risk Environments: Applications where continuous cable monitoring is essential for safety

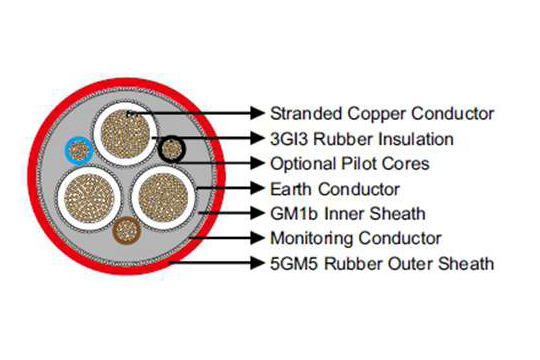

Construction

Advanced Multi-Layer Construction:

-

Conductors: Flexible stranded copper conductor, class 5 (DIN VDE 0295)

-

Inner Conductor Layer: Special rubber compound, conductive

-

Insulation: Rubber type 3GI3

-

Outer Conductor Layer: Special rubber compound, conductive, easy strippable

-

Pilot Cores (optional): Tinned copper conductor with EPR insulation

-

Earth Conductor: Spiral of tinned copper wires

-

Inner Sheath: Rubber type GM1b

-

Monitoring Shield/Armour: Braided armour of combined copper-steel wires; or wrap of copper and steel wires, copper tape in opposite direction, reinforcing tape

-

Outer Sheath: Rubber type 5GM5

Specifications

6/10kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 3×25+3×16/3E+3×2.5ST+6UEL | 48.0 | 52.0 | 3500 |

| 3×35+3×16/3E+3×2.5ST+6UEL | 51.0 | 55.0 | 3750 |

| 3×50+3×25/3E+3×2.5ST+6UEL | 56.0 | 60.0 | 4720 |

| 3×95+3×50/3E+3×2.5ST+6UEL | 66.0 | 71.0 | 7260 |

| 3×120+3×70/3E+6UEL | 70.0 | 75.0 | 9700 |

| 3×150+3×70/3E+6UEL | 73.0 | 78.0 | 9950 |

12/20 (24) kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 3×25+3×25/3E+6UEL | 62.0 | 67.0 | 5800 |

| 3×95+3×50/3E+6UEL | 74.0 | 78.0 | 11000 |

| 3×120+3×70/3E+6UEL | 80.0 | 85.0 | 13000 |

Key Advantages

-

Proven High Voltage Performance: Reliable operation at 6/10kV and 12/20kV in extreme mining conditions

-

Comprehensive Safety Monitoring: Integrated system detects both insulation faults and external damage

-

Superior Mechanical Strength: Withstands high mechanical loads while maintaining operational flexibility

-

Mobile Operation Capability: Unique design allows equipment movement during operation without power interruption

-

Robust Material Selection: High-quality rubber compounds and reinforced construction ensure long service life

-

Industry Standard Compliance: Manufactured according to German mining standards for maximum reliability and safety