Product Overview

Portable Arc-Welding Cable 600V is specifically engineered for flexible welding applications, providing reliable connections between electrode holders and welding machines in electric arc welding systems. Featuring heavy-duty EPR insulation and Class K/M stranded copper conductors, this cable delivers exceptional flexibility and durability for demanding welding environments.

Key Features & Benefits

-

Superior Flexibility: Class K/M stranded annealed copper conductors for easy handling and positioning

-

Heavy-Duty Protection: EPR jacket provides excellent mechanical and environmental resistance

-

High Temperature Performance: Rated for continuous operation at up to 90°C

-

Multiple Configuration Options: Available in heavy-duty and medium-duty constructions

-

Customizable Jacket: Alternative jacket materials and reinforced constructions available

-

Industry Compliance: Meets ICEA, ASTM, CSA, and UL standards for welding applications

Applications

Specifically designed for electric arc welding systems:

-

Welding Lead Connections: Flexible leads connecting electrode holders to welding machines

-

Secondary Circuit Applications: Electric arc welding system secondary circuits

-

Industrial Welding Operations: Manufacturing, construction, and repair welding applications

-

Portable Welding Equipment: Mobile welding setups requiring flexible cable solutions

-

Heavy-Duty Welding: Demanding welding environments requiring durable cable performance

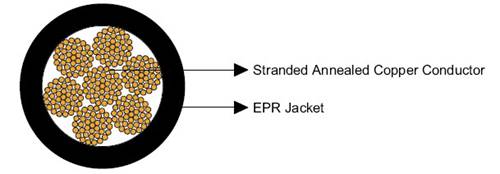

Construction

Optimized Construction for Welding Applications:

-

Conductors: Class K/M stranded annealed copper conductor

-

Jacket: Heavy-duty/medium-duty Ethylene Propylene Rubber (EPR)

Available Options:

-

Alternative jacket materials: CSP/PCP/NBR/PVC available upon request

-

Two-layer jacket with reinforcing fibre between layers available as option

Specifications

Detailed Technical Specifications:

| Construction | No. of Strands | Nominal Insulation Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | |

|---|---|---|---|---|---|---|

| No. of cores×AWG/kcmil | – | inch/mm | inch/mm | lbs/kft | kg/km | A |

| 1×6 | 259 | 0.060/1.5 | 0.37/9.4 | 124 | 184 | 125 |

| 1×4 | 420 | 0.060/1.5 | 0.42/10.7 | 180 | 268 | 182 |

| 1×2 | 665 | 0.060/1.5 | 0.49/12.5 | 268 | 399 | 271 |

| 1×1 | 836 | 0.080/2.0 | 0.53/13.3 | 319 | 475 | 360 |

| 1×1/0 | 1045 | 0.080/2.0 | 0.59/14.9 | 415 | 617 | 444 |

| 1×2/0 | 1330 | 0.080/2.0 | 0.64/16.3 | 508 | 756 | 535 |

| 1×3/0 | 1672 | 0.080/2.0 | 0.70/17.8 | 628 | 934 | 667 |

| 1×4/0 | 2107 | 0.080/2.0 | 0.81/20.7 | 775 | 1153 | 809 |

| 1×250 | 2499 | 0.095/2.4 | 0.88/22.4 | 934 | 1390 | 1048 |

| 1×350 | 3458 | 0.095/2.4 | 1.01/25.6 | 1267 | 1885 | 1396 |

| 1×500 | 5054 | 0.095/2.4 | 1.18/30.0 | 1801 | 2680 | 1973 |

Mechanical and Thermal Properties

Performance Specifications:

-

Minimum Bending Radius: 6 × Outer Diameter

-

Maximum Operating Temperature: +90°C

-

Ampacity Rating: As specified in table above

Standards Compliance

Applied Standards:

-

ICEA S-75-381/NEMA WC 58

-

ASTM B 172

-

ASTM B 33

-

CAN/CSA C22.2 No. 96

-

UL 1581

Key Advantages

-

Proven Reliability: Specifically designed for demanding welding applications

-

Enhanced Flexibility: Optimized conductor stranding for easy maneuverability

-

Durable Construction: EPR jacket withstands rough handling and environmental challenges

-

Safety Compliance: Meets all relevant industry standards for welding applications

-

Customizable Solutions: Multiple jacket options available for specific application needs