Product Overview

N3GHSSYCY Shielded Rubber-Insulated PVC Sheath Mining Cable is engineered for high-voltage applications in hazardous mining and tunneling environments. Featuring comprehensive shielding, monitoring conductors, and robust construction, this cable provides reliable energy supply to medium-voltage equipment while enabling continuous insulation monitoring for enhanced safety in underground operations.

Key Features & Benefits

-

Comprehensive Monitoring System: Phase-concentric earth conductor and monitoring shield enable continuous insulation fault detection

-

High Voltage Capability: Available in 3.6/6kV, 6/10kV, 8.7/15kV, and 12/20kV ratings

-

Enhanced Mobility: Designed for progressive unwinding as excavation work advances

-

Robust Mechanical Protection: Galvanized steel wire armour with multiple PVC sheaths

-

Superior Electrical Performance: Low capacitance design suitable for expanded 5kV networks

-

Environmental Adaptability: Suitable for both indoor and outdoor applications in harsh conditions

Applications

Critical high-voltage applications in mining and tunneling:

-

Mobile Operating Equipment: Energy supply to MV equipment in tunneling and underground mining

-

High-Voltage Transformers: Stationary operation in mining and tunneling applications

-

Progressive Excavation: Equipment shifted forward in stages as excavation work progresses

-

Hazardous Environments: Mines and underground excavations with dangerous conditions

-

10kV and 5kV Networks: Suitable for expanded networks due to low capacitance design

-

Container Installation: Mobile laying in containers with progressive unwinding capability

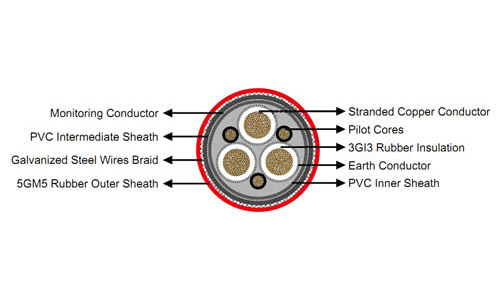

Construction

Advanced Multi-Layer Construction:

-

Conductors: Flexible stranded copper conductor, class 5 (DIN VDE 0295)

-

Insulation: EPR compound type 3GI3

-

Electrical Field Control: Inner and outer semiconductive layer of semiconductive rubber

-

Pilot Cores: Stranded copper conductor with EPR insulation

-

Earth Conductor: Spiral of copper wires over the outer semiconductive layer

-

Inner Sheath: PVC compound type YM5

-

Monitoring Conductor: Conductive tape serving and overall concentric Cu wire spinning

-

Intermediate Sheath: PVC compound type YM5

-

Armour: Braid of galvanized steel wires

-

Outer Sheath: PVC compound type YM5

Characteristics

Electrical & Mechanical Performance:

-

Voltage Rating (Uo/U): 3.6/6kV | 6/10kV | 8.7/15kV | 12/20kV

-

Test Voltage:

-

3.6/6kV: 11kV

-

6/10kV: 17kV

-

-

Maximum Short Circuit Temperature: +250°C

-

Maximum Working Temperature: +90°C (conductor)

-

Ambient Temperature:

-

Fixed: -40°C to +80°C

-

Flexed: +5°C to +80°C

-

-

Minimum Bending Radius:

-

Fixed: 6 × overall diameter

-

Flexed: 10 × overall diameter

-

-

Maximum Tensile Load: 15N/mm²

Standards Compliance

Applied Standards:

-

VDE 0250 Part 605

Specifications

3.6/6kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 3×25+3×16/3E+3×2.5ST+UEL | 49.0 | 53.0 | 4190 |

| 3×35+3×16/3E+3×2.5ST+UEL | 52.0 | 56.0 | 4800 |

| 3×50+3×25/3E+3×2.5ST+UEL | 55.0 | 59.0 | 5600 |

| 3×70+3×35/3E+3×2.5ST+UEL | 59.0 | 63.0 | 6650 |

| 3×95+3×50/3E+3×2.5ST+UEL | 63.0 | 67.0 | 7940 |

6/10kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 3×25+3×16/3E+3×2.5ST+UEL | 55.0 | 58.0 | 5300 |

| 3×35+3×16/3E+3×2.5ST+UEL | 58.0 | 61.0 | 5910 |

| 3×50+3×25/3E+3×2.5ST+UEL | 61.0 | 65.0 | 6790 |

| 3×70+3×35/3E+3×2.5ST+UEL | 65.0 | 69.0 | 7860 |

| 3×95+3×50/3E+3×2.5ST+UEL | 68.0 | 73.0 | 9180 |

8.7/15kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 3×25+3×16/3E+3×2.5ST+UEL | 58.0 | 62.0 | 6810 |

| 3×35+3×16/3E+3×2.5ST+UEL | 61.0 | 65.0 | 7850 |

| 3×50+3×25/3E+3×2.5ST+UEL | 64.7 | 68.7 | 9130 |

| 3×70+3×35/3E+3×2.5ST+UEL | 67.9 | 71.9 | 10750 |

| 3×95+3×50/3E+3×2.5ST+UEL | 72.4 | 76.4 | 12290 |

12/20kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 3×25+3×16/3E+3×2.5ST+UEL | 62.3 | 66.3 | 8790 |

| 3×35+3×16/3E+3×2.5ST+UEL | 65.3 | 69.3 | 9930 |

| 3×50+3×25/3E+3×2.5ST+UEL | 69.0 | 73.0 | 11360 |

| 3×70+3×35/3E+3×2.5ST+UEL | 72.2 | 76.2 | 13100 |

| 3×95+3×50/3E+3×2.5ST+UEL | 76.8 | 80.8 | 14750 |

Key Advantages

-

Advanced Safety Monitoring: Integrated monitoring system detects insulation faults and external damage

-

High Voltage Versatility: Multiple voltage ratings from 3.6/6kV to 12/20kV for various applications

-

Progressive Deployment: Mobile design allows unwinding as excavation operations progress

-

Robust Protection: Multiple protective layers including steel armour and PVC sheaths

-

Technical Compliance: Meets VDE 0250 Part 605 standards for mining applications

-

Reliable Performance: Maintains electrical integrity in harsh underground environments