Product Overview

Type G-GC (SHD-GC) Portable Mining Cable delivers 2000V power transmission for extreme mining environments. Featuring flat parallel construction with integrated ground-check monitoring, EPR insulation, and heavy-duty CPE jacket, it meets MSHA/ICEA S-75-381 for trailing applications in mines. Rated for 90°C operation with unmatched crush/abrasion resistance.

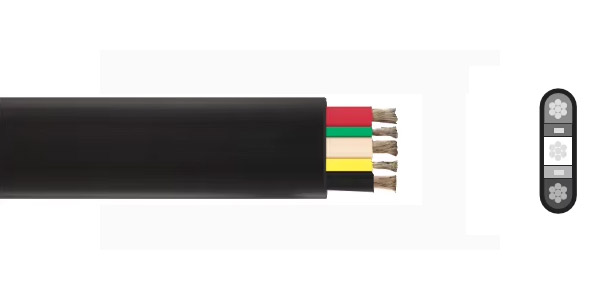

Construction

-

Conductor System:

-

Power Conductors (3): Rope-lay-stranded coated copper (6AWG to 500kcmil; ASTM B172)

-

Ground Conductor: Shaped copper w/green elastomer

-

Ground-Check: Yellow-insulated copper

-

Color ID: Black/White/Red (phase) + Green (ground) + Yellow (ground-check)

-

-

Insulation/Jacket:

-

Insulation: Ethylene Propylene Rubber (EPR)

-

Jacket: Lead-cured Chlorinated Polyethylene (CPE)

-

Technical Specifications

| No.of cond. | Conductor Size | Stranding | Ground Size | Ground Check | Insulation Thick. (mm) | Diameter (mm) | Copper Content (kg/km) | Net Weight (kg/km) |

|---|---|---|---|---|---|---|---|---|

| 3 | 10 AWG | 104/30 | 2×12 AWG | 12 AWG | 1.524 | 19.050 | 233 | 800 |

| 3 | 8 AWG | 133/29 | 2×10 AWG | 10 AWG | 1.524 | 22.987 | 379 | 893 |

| 3 | 6 AWG | 259/30 | 2×10 AWG | 10 AWG | 1.524 | 26.035 | 519 | 1153 |

| 3 | 4 AWG | 259/28 | 2×9 AWG | 10 AWG | 1.524 | 27.816 | 783 | 1600 |

| 3 | 2 AWG | 259/26 | 2×7 AWG | 8 AWG | 1.524 | 33.020 | 1248 | 2344 |

| 3 | 1 AWG | 259/25 | 2×6 AWG | 8 AWG | 2.032 | 37.973 | 1548 | 2827 |

| 3 | 1/0 AWG | 259-24 | 2×5 AWG | 8 AWG | 2.032 | 40.894 | 2098 | 3720 |

| 3 | 2/0 AWG | 259/23 | 2×4 AWG | 8 AWG | 2.032 | 43.942 | 2388 | 4464 |

| 3 | 4/0 AWG | 259/21 | 2×2 AWG | 8 AWG | 2.032 | 51.054 | 3757 | 6250 |

| 3 | 250 kcmil | 627/24 | 2×1 AWG | 8 AWG | 2.413 | 60.706 | 4345 | 7613 |

| 3 | 350 kcmil | 855/24 | 2×1/0 AWG | 8 AWG | 2.413 | 68.072 | 6093 | 10980 |

| 3 | 500 kcmil | 1235/24 | 2×3/0 AWG | 8 AWG | 2.413 | 76.962 | 8526 | 12224 |

Ampacity ratings per NEC 400.5 @ 90°C available upon request

Advantages

-

Ground Safety System

-

Real-time ground-check monitoring prevents electrocution hazards

-

Exceeds MSHA 30 CFR §75.900 grounding requirements

-

-

Extreme Durability

-

Flat parallel design withstands 2,000+ lbs crush load (3× round cables)

-

CPE jacket resists abrasion/cut-through >1,500 psi

-

-

Harsh Environment Resilience

-

Operational range: -40°C to 90°C

-

Resists oils, chemicals, steam, and UV degradation

-

-

Regulatory Compliance

-

MSHA-approved flame resistance

-

ICEA S-75-381 certified for mining trailing applications

-

-

Reduced Downtime

-

15,000 hours operational life in high-abrasion zones

-

40% lower replacement frequency vs. PVC cables

-

-

Optimized Installation

-

Shaped cores prevent conductor migration

-

Minimum bend radius = 6× cable diameter

-

Applications

-

Underground Mining: Continuous miners • Shuttle cars • Roof bolters

-

Surface Mining: Draglines • Excavators • Haul trucks

-

Critical Circuits: Pump stations • Ventilation systems • Emergency power

Compliance

-

Standards: ICEA S-75-381

-

Safety: MSHA Acceptance

-

Testing: IEEE 1202 Flame Resistance • ICEA T-28-562

-

Materials: RoHS • REACH

Engineering Selection Guide

| Parameter | Requirement | G-GC Solution |

|---|---|---|

| Crush Resistance | High (e.g., vehicle runovers) | Flat parallel design |

| Ground Monitoring | Mandatory per MSHA | Integrated ground-check |

| Voltage | ≤2000V | 2000V EPR insulation |

| Temperature | -40°C to +90°C | Full operational range |

| Chemical Exposure | Oils/solvents present | CPE jacket resistance |