Product Overview

Welding Cable 105°C 600V is a highly flexible, durable cable designed for demanding industrial welding applications. Featuring rope-lay Class K stranded copper conductors and flame-retardant ethylene propylene rubber (EPR) insulation, this cable operates reliably in temperatures ranging from -50°C to +105°C. Ideal for connecting electrode holders, clamps, and arc welders, it provides superior resistance to oil, abrasion, ozone, and solvents, ensuring safe and efficient power transmission in harsh environments.

Key Features

-

Extreme Flexibility: Class K stranded bare copper conductors (ASTM B-172) for superior bendability and repeated movement.

-

High-Temperature Resistance: Rated for continuous use at 105°C, with short-term tolerance up to 200°C.

-

Oil & Chemical Resistance: EPR insulation withstands oils, grease, solvents, and industrial chemicals.

-

Flame Retardancy: Self-extinguishing insulation reduces fire risks in spark-prone environments.

-

Durable Construction: Tape separator prevents insulation adhesion to conductors, enhancing longevity.

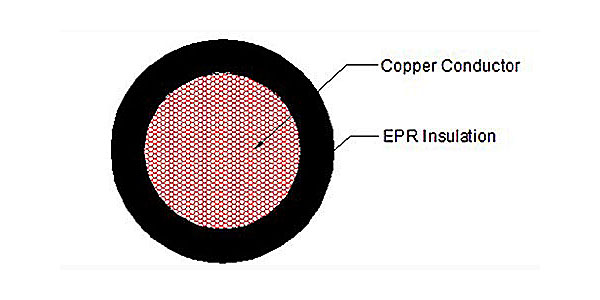

Construction Details

| Component | Specification |

|---|---|

| Conductor | Rope-lay Class K stranded soft-drawn bare copper (ASTM B-172 compliant). |

| Separator | Non-adhesive tape between conductor and insulation. |

| Insulation | Thermoplastic EPR (ethylene propylene rubber), flame/oil/abrasion resistant. |

| Voltage Rating | 600V AC. |

| Temperature Range | -50°C to +105°C (operating). |

| Color Options | Standard black or red (custom colors available). |

Technical Specifications

-

Standards Compliance: ASTM B-172 (conductors), industry-standard welding cable specifications.

-

Conductor Sizes: 6 AWG to 500 MCM (customizable upon request).

-

Insulation Thickness: Meets NEC requirements for voltage and mechanical protection.

-

Flame Performance: Passes UL VW-1 vertical flame test.

-

Cold Flexibility: Maintains pliability at -50°C for Arctic or cold storage applications.

Applications

Welding Cable 105°C 600V is engineered for:

-

Arc Welding Systems: Connections between electrode holders, transformers, and welding machines.

-

Industrial Machinery: Heavy-duty welding robots, automated welding lines, and foundries.

-

Construction Sites: Portable welders and temporary power feeds in harsh outdoor conditions.

-

Shipbuilding & Repair: Marine-grade welding applications with exposure to saltwater and humidity.

-

Mining & Oil Rigs: High-vibration environments requiring oil-resistant, flexible cables.

Installation Guidelines

-

Bending Radius: Minimum 6x cable diameter to avoid insulation damage.

-

Temperature Limits: Do not exceed 105°C during continuous operation.

-

Termination: Use crimped lugs or soldered connectors for secure joints.

-

Grounding: Follow NEC guidelines for proper equipment grounding.

-

Prohibited Uses: Not for fixed installations or direct burial unless specified.

Why Choose Welding Cable 105°C 600V?

-

Unmatched Flexibility: Class K stranding ensures easy handling in tight spaces.

-

Safety First: Flame-retardant EPR insulation minimizes fire hazards.

-

Durability: Resists cracking, abrasion, and degradation from oils/solvents.

-

Cost Efficiency: Long service life reduces downtime and replacement costs.

-

Versatility: Suitable for portable and stationary welding equipment.