Product Overview

DG Cable is a robust electrical power and control tray cable designed for reliable performance in industrial and commercial applications. Compliant with UL 3003 standards, this 600V-rated cable features dual-layer insulation (PVC + nylon), FT4 flame resistance, and RoHS/Reach compliance. Engineered for cable tray installations, it delivers durability, flexibility, and safety in demanding environments with a maximum operating temperature of 90°C.

Key Features

-

FT4 Flame Resistance: Meets stringent vertical flame propagation standards (70,000 Btu/hr).

-

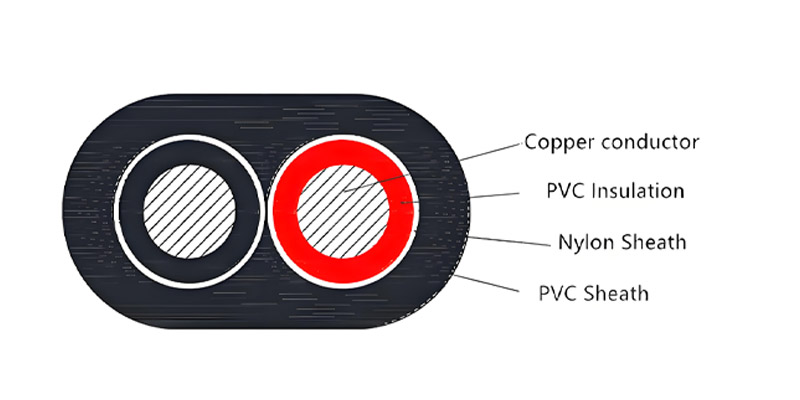

Dual-Layer Insulation: PVC inner insulation + nylon outer layer for enhanced mechanical and thermal protection.

-

UL 3003 Certified: Compliant with UL standards for power and control tray cables.

-

Environmental Compliance: RoHS and Reach certified for eco-friendly use.

-

Stranded Copper Conductors: 12 AWG bare copper ensures flexibility and conductivity.

-

Compact Design: Flat black PVC jacket (9.7mm x 6.1mm) for space-efficient tray routing.

Construction Details

| Component | Specification |

|---|---|

| Conductor | 12 AWG stranded copper (19/0.47mm strands, ASTM compliant). |

| Inner Insulation | PVC, 0.38mm avg. thickness; colors: black or red. |

| Outer Insulation | Nylon, 0.15mm avg. thickness; natural color. |

| Jacket | Black PVC, 1.14mm avg. thickness; dimensions: 9.70±0.30mm (W) x 6.10±0.20mm (H). |

| Voltage Rating | 600V AC. |

| Temperature Range | -40°C to +90°C (operating). |

Technical Specifications

-

Standards Compliance: UL 3003, FT4 Flame Test, RoHS, Reach.

-

Conductor Size: 12 AWG stranded copper.

-

Insulation Materials: PVC (inner) + nylon (outer).

-

Flame Retardancy: Passes FT4/IEEE 1202 vertical flame test.

-

Environmental Suitability: Dry and damp locations; resistant to abrasion and mild chemicals.

Applications

DG Cable is engineered for:

-

Industrial Control Systems: Power and signal distribution in cable trays.

-

Machinery Wiring: Control panels, motors, and automated equipment.

-

Commercial Buildings: HVAC systems, lighting circuits, and data centers.

-

Hazardous Areas: FT4-rated for environments requiring flame resistance.

-

Energy Infrastructure: Renewable energy plants and power distribution networks.

Installation Guidelines

-

Bending Radius: Minimum 6x cable height (6.1mm) to prevent jacket damage.

-

Temperature Limits: Install at ≥ -40°C using cold-weather handling practices.

-

Securing: Use UL-listed clamps or ties at ≤ 4.5 ft intervals in trays.

-

Prohibited Uses: Not rated for direct burial or prolonged UV exposure.

-

Grounding: Follow NEC guidelines for tray cable grounding.

Why Choose DG Cable?

-

Safety First: FT4 flame resistance reduces fire spread risks in critical installations.

-

Dual Insulation: Combines PVC’s electrical properties with nylon’s mechanical strength.

-

Regulatory Compliance: Meets UL, RoHS, and Reach requirements for global markets.

-

Space Efficiency: Flat-profile jacket optimizes space in crowded cable trays.

-

Cost-Effective: Long service life with minimal maintenance needs.