Product Overview

The MC Continuous Armored Cable Multi-Conductor XLP PVC 600V is a robust, versatile electrical cable designed for industrial, commercial, and hazardous environments. Combining cross-linked polyethylene (XLP) insulation, a corrugated aluminum armor sheath, and a durable PVC outer jacket, this cable offers superior mechanical protection, chemical resistance, and long-term reliability. It serves as a cost-effective alternative to conduit systems, supporting power distribution, lighting, control, and signal circuits in diverse installations.

Key Features:

-

Compliance: Meets ICEA standards (Method 1, Table E-2), NEC, and UL guidelines.

-

Temperature Rating: 90°C (dry/wet).

-

Voltage Rating: 600V.

-

Hazardous Location Approval: Suitable for Class I Div 2, Class II Div 2, and Class III environments.

Technical Specifications

| Parameter | Description |

|---|---|

| Conductor | Stranded copper, compact stranding for #8 AWG and larger. |

| Insulation | XLP (Cross-Linked Polyethylene) insulation. Color-coded per ICEA Method 1. |

| Armor | Continuous corrugated aluminum sheath for crush resistance and EMI shielding. |

| Outer Jacket | UV-resistant PVC, black. Protects against moisture, abrasion, and chemicals. |

| Conductor Sizes | #14 AWG – #10 AWG (smaller gauges) / #8 AWG and larger (compact stranded). |

| Temperature Range | -40°C to +90°C (operating), 90°C (max working temp, dry or wet). |

| Installation | Direct burial, cable tray, raceways, open runs, aerial (with messenger). |

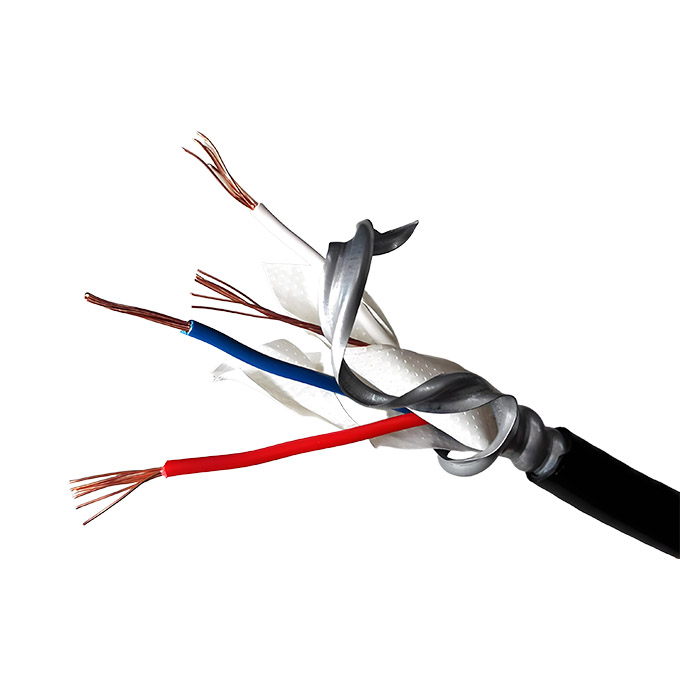

Construction Details

-

Conductor:

-

High-purity stranded copper for flexibility and conductivity.

-

Compact stranding for larger gauges (#8 AWG+) to optimize space and performance.

-

-

Insulation:

-

XLP (Cross-Linked Polyethylene): Superior thermal stability (90°C), moisture resistance, and dielectric strength.

-

Color-coded insulation simplifies phase identification (ICEA Method 1, Table E-2).

-

-

Assembly:

-

Cabled with non-hygroscopic fillers to prevent moisture ingress.

-

Binder tape ensures core integrity during installation.

-

-

Armor & Jacket:

-

Corrugated Aluminum Armor: Provides mechanical protection, grounding continuity, and EMI shielding.

-

PVC Outer Jacket: Resists environmental stress, chemicals, and UV degradation.

-

Applications

-

Industrial Facilities: Feeders, branch circuits, motor controls.

-

Commercial Buildings: Lighting, HVAC systems, data centers.

-

Hazardous Locations: Class I Div 2 (flammable gases), Class II Div 2 (combustible dust), Class III (ignitable fibers).

-

Outdoor/Underground: Direct burial, aerial installations, wet/dry locations.

-

Infrastructure: Cable trays, raceways, open runs, and signal/control circuits.

Advantages for Engineers

-

Durability: Aluminum armor and PVC jacket ensure longevity in harsh conditions.

-

Versatility: Eliminates conduit needs, reducing labor and material costs.

-

Safety: Meets NEC/UL standards for hazardous locations and wet environments.

-

Easy Identification: ICEA-compliant color coding simplifies installation and maintenance.

Standards & Certifications

-

ICEA S-95-658/NEMA WC70 (Conductor insulation and assembly).

-

UL 1569 (Metal-clad cables).

-

NEC Articles 330, 725, 770 (Installation compliance).

Ordering Information

Specify conductor size, number of conductors, and length. Custom configurations available for specialized requirements.