Product Overview

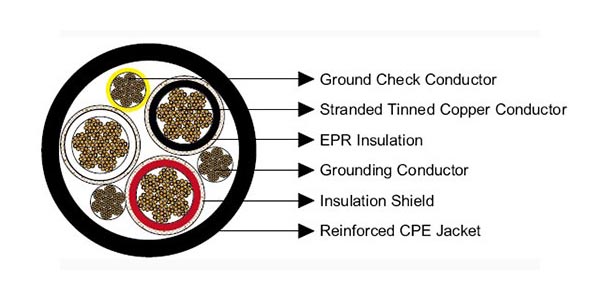

Type SHD-GC Power Cable is a shielded, round portable cable engineered for high-voltage trailing applications in mining and heavy industrial environments. Rated for 2kV to 25kV and 90°C operation, it features ethylene propylene rubber (EPR) insulation, a reinforced CPE jacket, and integrated ground-check monitoring. Compliant with ICEA S-75-381 and MSHA standards, this cable delivers exceptional resistance to oil, chemicals, abrasion, and flame, ensuring safe power transmission for longwall shearers, AC mining equipment, and other high-risk applications.

Key Features

-

Fail-Safe Ground-Check System: Integrated yellow polypropylene-insulated ground-check conductor for real-time safety monitoring.

-

High Voltage Capacity: Rated for 2kV to 25kV systems with shielded design to mitigate induced voltages.

-

Robust Shielding: Flexible copper/textile braid shield over non-conductive tape for EMI and shock hazard protection.

-

Mining-Grade Durability: Dual-layer CPE jacket resists cuts, oil, steam, and radiation.

-

MSHA Compliance: Meets flame test requirements for hazardous mining environments.

Construction Details

| Component | Specification |

|---|---|

| Conductor | 6 AWG to 500 kcmil coated annealed copper, rope-lay-stranded (ASTM B172). |

| Insulation | Ethylene Propylene Rubber (EPR), thermal stability up to 90°C. |

| Insulation Shield | Copper/textile braid over non-conductive tape for uniform voltage distribution. |

| Ground-Check Conductor | Annealed copper, insulated with yellow polypropylene (ASTM B172 compliant). |

| Grounding Conductors | Two coated copper conductors bonded to copper braid shield. |

| Jacket | Dual-layer lead-cured Chlorinated Polyethylene (CPE), abrasion and oil resistant. |

| Voltage Rating | 2kV to 25kV AC. |

| Temperature Range | -40°C to +90°C (wet/dry). |

Technical Specifications

-

Standards Compliance: ICEA S-75-381, MSHA flame tests, ASTM B172.

-

Flame Resistance: Passes UL VW-1 and FT4/IEEE 1202 vertical flame tests.

-

Shielding Efficiency: Copper braid shield ensures EMI protection and fault current management.

-

Environmental Resistance: Oil, chemicals, steam, UV, and abrasion.

-

Ground-Check System: Monitors ground continuity to prevent electrical hazards.

Applications

Type SHD-GC Cable is engineered for:

-

Mining Operations: Trailing cables for longwall shearers, continuous miners, and haul trucks.

-

High-Voltage Equipment: AC circuits in underground mining and tunneling machinery.

-

Hazardous Locations: Environments requiring shielded cables and ground-check monitoring.

-

Industrial Plants: Heavy-duty power feeds for crushers, conveyors, and processing systems.

-

Temporary Installations: Mobile generators and emergency power systems in harsh conditions.

Installation Guidelines

-

Bending Radius: Minimum 10x cable diameter to prevent shield/jacket damage.

-

Grounding: Bond copper braid shield and grounding conductors per MSHA/NEC standards.

-

Pull Tension: Use MSHA-approved grips to avoid conductor deformation during installation.

-

Temperature Limits: Avoid installation below -40°C without pre-conditioning.

-

Prohibited Uses: Not for direct burial unless armored or specified.

Why Choose Type SHD-GC Power Cable?

-

Safety Assurance: Ground-check conductor ensures continuous monitoring of grounding integrity.

-

Durability: Reinforced CPE jacket withstands mechanical stress and harsh chemicals.

-

Compliance: Meets MSHA and ICEA standards for legal and operational safety.

-

Flexibility: Rope-lay stranding allows easy handling in dynamic mining applications.

-

Longevity: EPR insulation maintains performance under continuous 90°C loads.