Product Overview

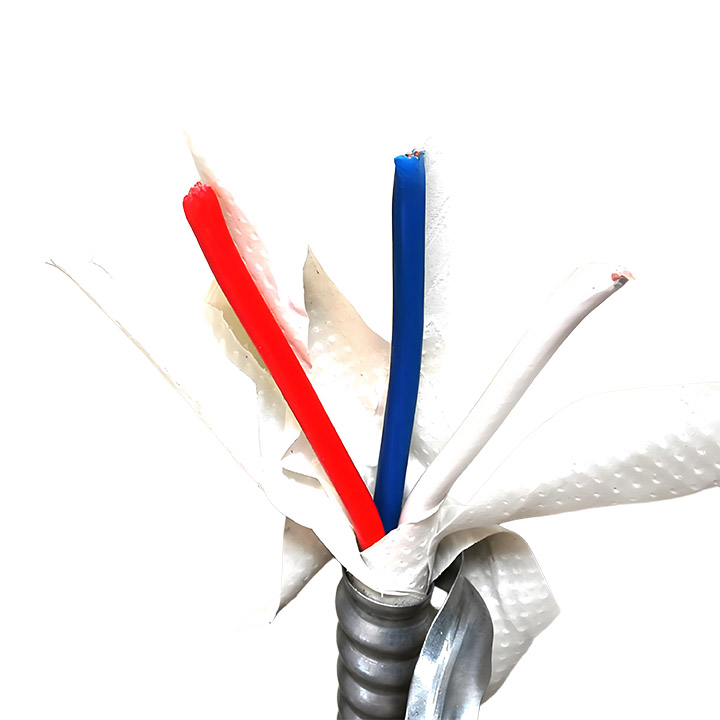

The Low Voltage Control Multi-Conductor Cable is a versatile, cost-effective solution designed for industrial and commercial control, signal, and power circuits. Engineered to replace traditional conduit systems, this cable features stranded copper conductors, color-coded insulation, and a durable corrugated aluminum armor with an outer jacket. Suitable for indoor/outdoor, wet/dry, and hazardous locations, it simplifies installations in cable trays, raceways, direct burial, or aerial applications.

Key Features:

-

Voltage Rating: Low voltage (600V max).

-

Temperature Rating: 90°C (dry or wet).

-

Hazardous Location Compliance: Class I, Division 1 (NEC Article 501).

-

Construction: Compact stranding for #8 AWG and larger, corrosion-resistant aluminum armor.

Technical Specifications

| Parameter | Description |

|---|---|

| Conductor | Stranded copper; compact stranding for #8 AWG and larger (ASTM B3/B8 compliant). |

| Insulation | Color-coded thermoplastic insulation for easy phase identification. |

| Core Assembly | Non-hygroscopic fillers, binder tape, and ground wire (optional). |

| Armor | Corrugated aluminum sheath for mechanical protection and EMI shielding. |

| Jacket | UV-resistant, moisture-proof outer jacket. |

| Conductor Sizes | #14 AWG – #10 AWG (smaller gauges); #8 AWG+ with compact stranding. |

| Temperature Range | -40°C to +90°C (operating). |

| Installation | Direct burial, cable trays, raceways, open runs, aerial (with messenger). |

Construction Details

-

Conductor:

-

High-conductivity stranded copper ensures flexibility and durability.

-

Compact stranding for #8 AWG and larger reduces cable diameter without compromising performance.

-

-

Insulation & Identification:

-

Thermoplastic insulation rated for 90°C in wet/dry conditions.

-

ICEA-compliant color coding simplifies circuit identification and maintenance.

-

-

Assembly:

-

Non-hygroscopic fillers prevent moisture absorption and maintain core integrity.

-

Optional bare copper ground wire included for NEC compliance.

-

-

Armor & Jacket:

-

Corrugated Aluminum Armor: Protects against crush damage, rodents, and EMI.

-

Outer Jacket: Resists UV radiation, chemicals, and abrasion for long-term durability.

-

Applications

-

Industrial Control Systems: PLCs, motor controls, sensors, and automation networks.

-

Commercial Infrastructure: Lighting, HVAC, and low-voltage power distribution.

-

Hazardous Environments: Class I, Division 1 locations (flammable gas/vapor areas).

-

Outdoor/Exposed Installations: Direct burial, cable trays, aerial messenger lines.

-

Signal & Data Circuits: Reliable performance in EMI-prone environments.

Compliance & Standards

-

NEC Compliance: Articles 501 (hazardous locations), 725 (signal circuits), 330 (metal-clad cable).

-

ICEA Standards: Conductor stranding and insulation color coding.

-

UL Certification: Meets UL 1569 for metal-clad cables.

Engineering Advantages

-

Cost Efficiency: Eliminates conduit costs with integrated armor protection.

-

Flexibility: Compact stranding and lightweight design simplify routing in tight spaces.

-

Durability: Aluminum armor and rugged jacket ensure reliability in harsh conditions.

-

Safety: NEC-compliant for hazardous locations and wet environments.

Ordering Information

Specify conductor size (#14 AWG – #10 AWG), number of conductors, ground wire requirement, and length. Custom configurations available for specialized projects.