Product Overview

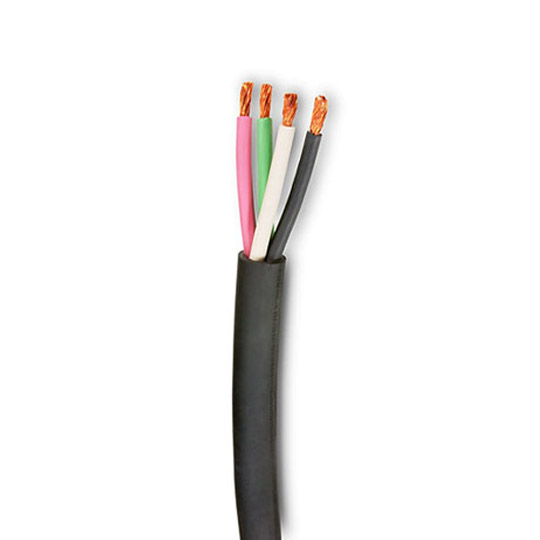

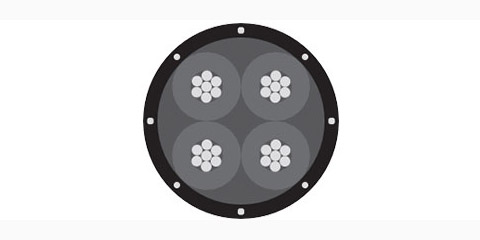

Type W Power, Round Portable Cable is a heavy-duty, four-conductor trailing cable designed for rugged mining and industrial applications. Rated for 2000V and 90°C operation, it features ethylene propylene rubber (EPR) insulation, reinforced dual-layer CPE jacket, and rope-lay-stranded copper conductors. Compliant with ICEA S-75-381 and MSHA standards, this cable delivers exceptional resistance to oil, chemicals, abrasion, and flame, making it ideal for AC-powered mining equipment and high-stress environments where ground-check monitoring is unnecessary.

Key Features

-

Extreme Flexibility: Rope-lay-stranded copper conductors (ASTM B172) prevent wire breakage during repeated bending.

-

Dual-Layer Protection: Reinforced CPE jacket resists cuts, impacts, UV radiation, and harsh chemicals.

-

Hazardous Environment Rated: MSHA-approved and flame-retardant (passes UL VW-1/FT4 tests).

-

Thermal Stability: Maintains physical properties across a broad temperature range (-40°C to +90°C).

-

Color-Coded Insulation: EPR insulation in black, white, red, and green for easy phase identification.

Construction Details

| Component | Specification |

|---|---|

| Conductor | 6 AWG to 500 kcmil coated annealed copper, rope-lay-stranded (ASTM B172). |

| Insulation | Ethylene Propylene Rubber (EPR), color-coded (black/white/red/green). |

| Jacket | Dual-layer lead-cured Chlorinated Polyethylene (CPE), abrasion and oil resistant. |

| Voltage Rating | 2000V AC. |

| Temperature Range | -40°C to +90°C (wet/dry). |

| Certifications | ICEA S-75-381, MSHA, ASTM B172. |

Technical Specifications

-

Standards Compliance: ICEA S-75-381, MSHA flame test, UL VW-1/FT4.

-

Conductor Sizes: 6 AWG to 500 kcmil.

-

Flame Resistance: Meets MSHA and UL vertical flame propagation requirements.

-

Environmental Resistance: Oil, steam, chemicals, UV, and abrasion.

-

Shielding: Not required for applications without induced voltage hazards.

Applications

Type W Power Cable is engineered for:

-

Mining Operations: Trailing cables for AC-powered drills, loaders, and haul trucks.

-

Heavy Machinery: Draglines, excavators, and underground mining vehicles.

-

Industrial Plants: High-voltage equipment in oil refineries and chemical facilities.

-

Tunneling & Construction: Rugged power distribution in confined, high-vibration spaces.

-

Outdoor Installations: Renewable energy sites and temporary power systems.

Installation Guidelines

-

Bending Radius: Minimum 8x cable diameter to prevent insulation/jacket damage.

-

Grounding: Ensure proper bonding of grounding conductors per NEC/MSHA standards.

-

Pulling Tension: Use MSHA-approved grips to avoid conductor deformation.

-

Temperature Handling: Avoid installation below -40°C without pre-conditioning.

-

Prohibited Uses: Not for environments requiring ground-check monitoring or direct burial.

Why Choose Type W Power Cable?

-

Unmatched Durability: Reinforced CPE jacket withstands cuts, impacts, and abrasion.

-

Safety Compliance: MSHA and ICEA certifications ensure safe operation in hazardous areas.

-

Flexibility: Rope-lay stranding allows easy handling in dynamic applications.

-

Thermal Performance: Stable across extreme temperatures (-40°C to +90°C).

-

Cost Efficiency: Long service life reduces downtime and replacement costs.

| NO. OF COND. | COND. SIZE (AWG/kcmil) | COND. STRAND | NOMINAL INSULATION THICKNESS (mm) | NOMINAL CABLE O.D. (mm) | COPPER WEIGHT (kg/km) | NET WEIGHT (kg/km) |

|---|---|---|---|---|---|---|

| 4 | 6 | 133 | 1.5 | 27.9 | 507 | 1247 |

| 4 | 4 | 259 | 1.5 | 32.3 | 779 | 1747 |

| 4 | 3 | 259 | 1.5 | 34 | 988 | 2049 |

| 4 | 2 | 259 | 1.5 | 37.6 | 1239 | 2531 |

| 4 | 1 | 259 | 2 | 42.7 | 1610 | 3262 |

| 4 | 1/0 | 259 | 2 | 45.5 | 2025 | 3793 |

| 4 | 2/0 | 329 | 2 | 49 | 2572 | 4581 |

| 4 | 3/0 | 413 | 2 | 52.6 | 3228 | 5485 |

| 4 | 4/0 | 532 | 2 | 57.4 | 4199 | 6758 |

| 4 | 250 | 608 | 2.4 | 67.6 | 4798 | 8553 |

| 4 | 350 | 851 | 2.4 | 75.7 | 6748 | 11275 |

| 4 | 500 | 1221 | 2.4 | 86.4 | 9682 | 15441 |