Product Overview

The Primary URD 5kV-46kV Copper Wire Shield Cable is a robust, medium-to-high voltage underground residential distribution (URD) cable engineered for industrial, commercial, and utility power systems. Designed to handle line-to-ground fault currents, this cable features a copper wire shield, thermoset EPR insulation, and UV-resistant jacketing, ensuring reliability in underground, duct, or direct burial installations. Compliant with UL, ICEA, and AEIC standards, it delivers superior electrical performance, moisture resistance, and thermal stability for critical power networks.

Key Features:

-

Voltage Range: 5kV to 46kV (100% and 133% insulation levels).

-

Temperature Ratings: 90°C (normal), 140°C (emergency), 250°C (short circuit).

-

Water Resistance: Optional dual-sealed design (strand + neutral fill) for ICEA-T-31-610/664 compliance.

-

Standards: UL 1072, ICEA S-94-649, AEIC CS8.

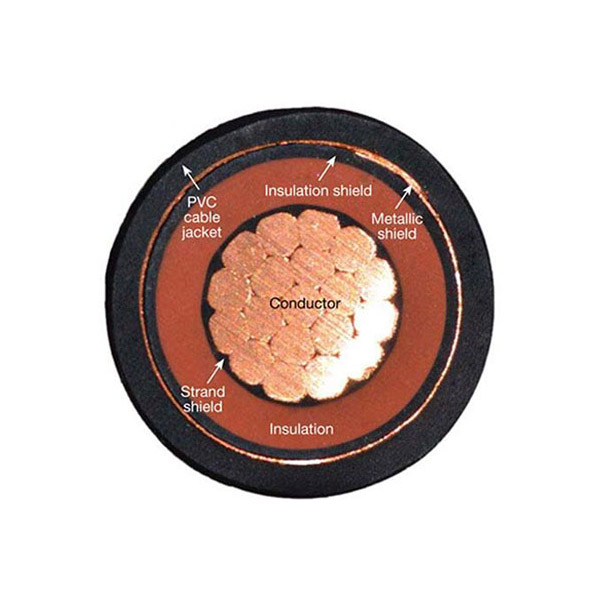

Technical Specifications

| Parameter | Description |

|---|---|

| Conductor | Soft annealed copper (ASTM B496) or hard-drawn aluminum (ASTM B231), Class B compressed. |

| Conductor Shield | Semi-conductive XLPE for uniform electric field distribution. |

| Insulation | Thermoset Ethylene Propylene Rubber (EPR), high dielectric strength. |

| Insulation Shield | Semi-conductive XLPE to minimize partial discharge. |

| Metallic Shield | Helically applied, spaced solid copper wires (ASTM B3) or copper tape. |

| Jacket | UV-resistant LLDPE (black with red stripes) or PVC. |

| Voltage Rating | 5kV–46kV (100% and 133% insulation levels). |

| Temperature Range | Normal: 90°C, Emergency: 140°C, Short Circuit: 250°C (wet/dry). |

| Water Blocking | Optional: Strand-filled compound (15 psi/60 mins) or dual-sealed (ICEA-T-34-664). |

Construction Details

-

Conductor:

-

Copper: Soft annealed, Class B compressed for flexibility and conductivity.

-

Aluminum (Optional): Hard-drawn 1350 alloy for lightweight, cost-effective solutions.

-

-

Shielding System:

-

Conductor Shield: Semi-conductive XLPE ensures smooth voltage gradient.

-

Insulation: EPR provides thermal stability, corona resistance, and flexibility.

-

Insulation Shield: XLPE layer to prevent electrical stress concentration.

-

Metallic Shield: Copper wire/tape shields for fault current management and EMI protection.

-

-

Jacket:

-

LLDPE: Sunlight-resistant, abrasion-proof, and suitable for direct burial.

-

PVC (Optional): Flame-retardant alternative for duct installations.

-

-

Water Blocking (Optional):

-

Strand Fill: Prevents longitudinal water ingress (ICEA-T-31-610 compliant).

-

Dual Seal: Combined conductor and neutral sealing (ICEA-T-34-664).

-

Applications

-

Utility Networks: Primary power distribution in residential/commercial URD systems.

-

Industrial Plants: Feeder circuits for machinery, substations, and generating stations.

-

Harsh Environments: Direct burial, wet locations, or ducts with high moisture exposure.

-

Renewable Energy: Interconnection cables for solar/wind farms.

Compliance & Certifications

-

UL 1072: Medium-voltage power cable standards.

-

ICEA S-94-649: Shielded power cables (5kV–46kV).

-

AEIC CS8: Utility-grade shielded cable specifications.

-

Water Penetration: ICEA-T-31-610 (strand fill) and ICEA-T-34-664 (dual seal).

Engineering Advantages

-

Fault Tolerance: Copper shield safely dissipates fault currents, protecting equipment.

-

Thermal Resilience: EPR insulation withstands extreme temperatures (250°C short circuit).

-

Durability: LLDPE/PVC jacket resists UV, chemicals, and mechanical stress.

-

Customization: Optional water-blocking designs for flood-prone or underground installations.

Ordering Information

Specify:

-

Conductor type (copper/aluminum).

-

Voltage rating (5kV–46kV).

-

Jacket material (LLDPE or PVC).

-

Water-blocking option (strand fill or dual seal).