Product Overview

TC Tray Cable FR-XLPE/PVC is a high-performance power and control cable designed for versatile industrial and commercial applications. Featuring flame-retardant XLPE insulation, sunlight-resistant PVC jacket, and ASTM-compliant copper conductors, this cable meets UL 1277 (TC/TC-ER), UL 44, and NEC standards for use in cable trays, direct burial, and hazardous locations. Rated for 600V and 90°C operation in wet/dry environments, it combines durability, safety, and compliance with critical flame and chemical resistance.

Key Features

-

Hazardous Location Rated: Approved for Class I, Division 2 areas (NEC compliant).

-

Dual Environmental Resistance: UV, weather, abrasion, and chemical-resistant construction.

-

Flame Retardancy: Passes UL 1581/UL 2556 VW-1 flame tests for vertical flame resistance.

-

Direct Burial Capable: Suitable for underground installations without additional conduit.

-

Exposed Run (ER) Rated: UL 1277 TC-ER certified for exposed tray applications.

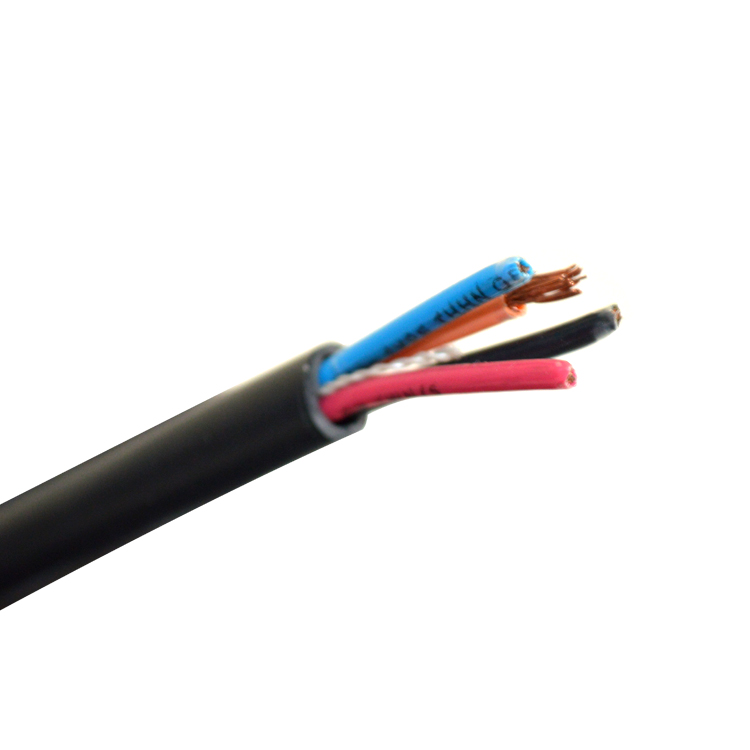

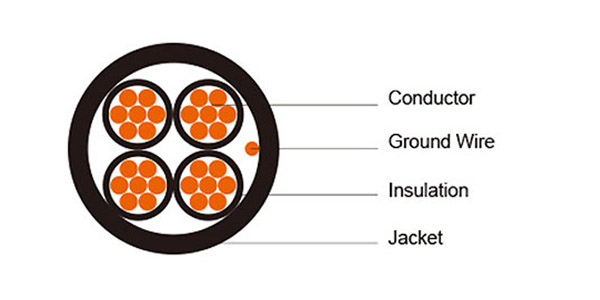

Construction Details

| Component | Specification |

|---|---|

| Conductor | Bare annealed copper (14 AWG to 750 kcmil), ASTM B3/B8 Class B stranding. |

| Insulation | Flame-retardant XLPE (cross-linked polyethylene), color-coded per ICEA Method 4. |

| Grounding Conductor | Uninsulated bare copper (ASTM B3/B8 compliant). |

| Jacket | Lead-free, flame-retardant PVC (sunlight/weather resistant). |

| Voltage Rating | 600V AC. |

| Temperature Range | -40°C to +90°C (wet/dry). |

Technical Specifications

-

Standards Compliance: UL 1277 TC/TC-ER, UL 44 (XHHW-2), UL 1581, ICEA S-95-658/NEMA WC70.

-

Flame Test Ratings: VW-1 (UL 2556), FT4 (IEEE 1202).

-

Conductor Sizes: 14 AWG to 750 kcmil.

-

Insulation Thickness: Meets ICEA/NEMA specifications for electrical integrity.

-

Environmental Suitability: Wet/dry locations, direct burial, UV exposure, and hazardous areas.

Applications

TC Tray Cable FR-XLPE/PVC is engineered for:

-

Industrial Power Distribution: Cable trays, raceways, and exposed runs in plants.

-

Hazardous Locations: Class I, Division 2 areas (refineries, chemical plants).

-

Outdoor Installations: Solar farms, wind turbines, and outdoor substations.

-

Infrastructure Projects: Water treatment facilities, tunnels, and transportation hubs.

-

Data Centers: Power and control circuits in raised floor environments.

-

Direct Burial: Underground power feeds without conduit protection.

Installation Guidelines

-

Bending Radius: Minimum 6x cable diameter for tray or exposed runs.

-

Direct Burial: Ensure proper trench depth and bedding material per NEC guidelines.

-

Securing: Use UL-listed clamps at ≤ 4.5 ft intervals in trays.

-

Terminations: Use NEC-compliant connectors for hazardous locations.

-

Prohibited Uses: Avoid continuous immersion unless specified for wet locations.

Why Choose TC Tray Cable FR-XLPE/PVC?

-

Safety Assurance: Flame-retardant XLPE and PVC reduce fire propagation risks.

-

Durability: Resists moisture, chemicals, and mechanical stress in harsh environments.

-

Regulatory Compliance: Meets UL, NEC, and ICEA standards for global acceptance.

-

Cost Efficiency: Eliminates conduit needs for direct burial and tray installations.

-

Versatility: Suitable for power, control, and instrumentation circuits.