Product Overview

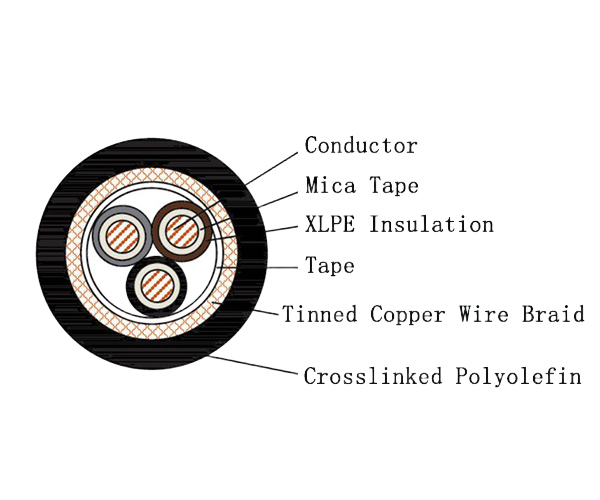

The CJ85/NC is a compact and high-performance fire resistant marine cable, designed with a streamlined construction that omits a separate inner sheath. It combines a fire-survival core of Mica Glass Tape + XLPE insulation (IEC 60331) with a flexible tinned copper wire braid armor and a robust, high-grade Cross-linked Polyolefin (SHF2) outer sheath. This design delivers certified circuit integrity during a fire, superior long-term sheath durability, and excellent mechanical protection in a more efficient package, ideal for space-constrained or demanding installations in critical marine and industrial environments.

Key Features & Benefits

-

Certified Fire Resistance (IEC 60331): Ensures vital emergency circuits (e.g., emergency lighting, fire alarms, pump controls) maintain operation for a specified duration under fire conditions, which is crucial for life safety and asset protection.

-

Compact & Efficient Structure: The absence of a separate inner sheath results in a more streamlined and potentially lighter cable, optimizing space and material use while maintaining all essential protective functions.

-

High-Performance Outer Sheath (SHF2): The Cross-linked Polyolefin (SHF2) outer sheath provides exceptional resistance to high temperatures, deformation, cracking, chemicals, and abrasion, far exceeding the performance of standard thermoplastic sheaths.

-

Flexible & Corrosion-Resistant Armor: A braid of tinned copper wires offers excellent flexibility for installation, ease of termination, and reliable corrosion resistance in marine and humid environments.

-

Enhanced Fire Safety (LSZH): As an NC-grade cable, it is Halogen Free and Low Smoke, minimizing corrosive gas emission and smoke density to facilitate safer evacuation and protect equipment.

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Mica Glass Tape + XLPE Insulated |

| Inner Sheath | \ | None (No separate inner sheath) |

| Armour | 8 | Braid of Tinned or Plain Copper Wires |

| Outer Sheath | 5 | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Flammability Class | NC | Halogen Free, Low Smoke, Fire Resistant |

| Sheath Colour | / | Standard Black (Other colours on request) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Mica Glass Tape + Cross-Linked Polyethylene (XLPE) |

| Armour | Braided Tinned/Plain Copper Wires |

| Outer Sheath | Cross-linked Polyolefin (SHF2) |

| Fire Resistance | IEC 60331 |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Halogen Content | IEC 60754-1 (Halogen Free) |

| Smoke Density | IEC 61034-2 (Low Smoke) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

Manufactured to the highest international standards for fire safety, marine application, and material performance:

-

IEC 60092-350, 353: Electrical installations in ships – Design.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60331: Tests for fire resistant characteristics.

-

IEC 60332-1 & -3-22: Tests for flame retardancy.

-

IEC 60754-1: Test on gases evolved during combustion (Halogen Free).

-

IEC 61034-2: Measurement of smoke density (Low Smoke).

Typical Applications

-

Marine & Offshore: Critical emergency and safety circuits on ships, offshore platforms, and in engine rooms where space is at a premium, and a compact yet high-performance fire-resistant cable is required. Ideal for emergency lighting, alarm systems, and control circuits for essential services.

-

Industrial & High-Risk Facilities: Power supply for life-safety systems in industrial plants, power generation facilities, and tunnels where the combination of fire survival, a durable SHF2 sheath for harsh environments, and a compact cable design are key requirements.