Product Overview

The CJ82SA is a streamlined, cost-effective armored marine power cable featuring a simplified construction without a separate inner sheath. It utilizes standard XLPE insulation for reliable electrical performance and is protected by a flexible tinned copper wire braid armor, all encased within a durable PVC outer sheath. This design offers a lightweight, economical solution for power, lighting, and control circuits in marine and industrial environments where standard flame retardancy (SA grade), EMI shielding, and flexible mechanical protection are required in a compact and efficient cable design.

Key Features & Benefits

-

Compact & Economical Design: The construction omits a separate inner sheath, resulting in a more streamlined, potentially lighter, and cost-effective cable structure, suitable for cost-conscious projects without compromising core functionality.

-

Flexible & Corrosion-Resistant Armor: The braided armor of tinned copper wires provides excellent flexibility for easier installation and routing, good tensile strength, and inherent corrosion resistance, making it well-suited for marine and humid atmospheres.

-

Standard Flame Retardancy (SA): Complies with IEC flame retardant standards for bunched cables (Category A), helping to inhibit the spread of flame along cable runs under defined test conditions.

-

Reliable Electrical Performance: XLPE (Cross-Linked Polyethylene) insulation ensures good dielectric properties and thermal stability for continuous operation at temperatures up to 90°C.

-

Durable External Protection: The PVC outer sheath offers essential resistance to abrasion, moisture, oils, and general environmental exposure.

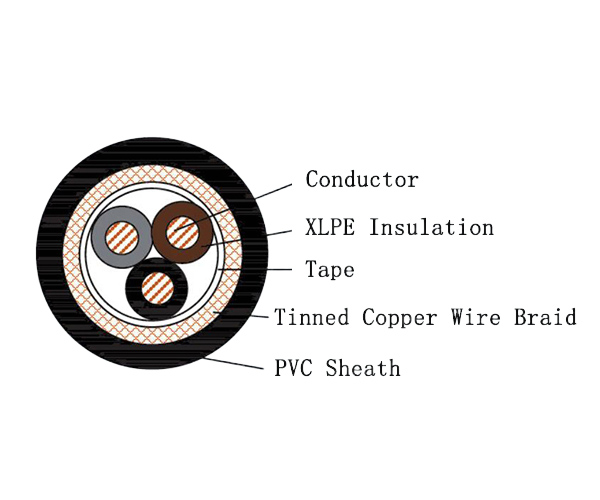

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Cross-Linked Polyethylene (XLPE) Insulated |

| Inner Sheath | \ | None (No separate inner sheath) |

| Armour | 8 | Braid of Tinned or Plain Copper Wires |

| Outer Sheath | 2 | Polyvinyl Chloride (PVC) Outer Sheath |

| Flammability Class | SA | Flame Retardant |

| Sheath Colour | / | Standard Black (Other colours on request) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Cross-Linked Polyethylene (XLPE) |

| Armour | Braided Tinned/Plain Copper Wires |

| Outer Sheath | Polyvinyl Chloride (PVC) |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

This cable is designed and manufactured in accordance with the following international standards:

-

IEC 60092-350, 353: Electrical installations in ships – Design.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60332-1: Test for vertical flame propagation for a single wire/cable.

-

IEC 60332-3-22: Test for vertical flame spread of bunched cables – Category A.

Typical Applications

-

Marine & General Industry: General power, lighting, and auxiliary control circuits on ships, in shipyards, and industrial plants where a compact, flexible armored cable with standard flame retardancy is sufficient. Ideal for use in cable trays, along bulkheads, or in protected conduits.

-

Infrastructure & Utilities: Cost-effective power distribution for non-critical circuits in infrastructure projects, water treatment plants, and general manufacturing facilities where mechanical protection and basic flame safety are required.