Product Overview

The CJ85/SC is a streamlined, high-performance marine power cable that features a simplified construction without a separate inner sheath, designed for efficiency and durability. It combines reliable XLPE insulation with a flexible tinned copper wire braid armor, all protected by a premium Cross-linked Polyolefin (SHF2) outer sheath. This design provides exceptional resistance to heat deformation, chemicals, and abrasion, while ensuring Halogen-Free, Low-Smoke (LSZH) flame retardant (SC grade) safety. Ideal for demanding marine and industrial fixed installations where space optimization, environmental toughness, and enhanced fire safety are key requirements.

Key Features & Benefits

-

Compact & Efficient Design: The absence of a separate inner sheath creates a more streamlined, lightweight, and space-efficient cable structure, facilitating easier handling and installation in confined spaces.

-

High-Performance Outer Sheath (SHF2): The Cross-linked Polyolefin (SHF2) outer sheath offers superior long-term resistance to high temperatures, deformation, cracking, chemicals, oils, and abrasion compared to standard thermoplastics, ensuring extended cable life in harsh conditions.

-

Flexible & Corrosion-Resistant Armor: A braid of tinned copper wires provides excellent flexibility for routing, good mechanical protection, and inherent corrosion resistance, making it well-suited for marine and humid environments.

-

Enhanced Fire Safety (LSZH): As an SC-grade cable, it is Halogen Free and Low Smoke (LSZH), significantly reducing the emission of corrosive/toxic gases and smoke density in case of fire to enhance personnel safety and protect equipment.

-

Reliable Electrical Core: XLPE (Cross-Linked Polyethylene) insulation ensures stable electrical characteristics and thermal endurance for continuous operation at 90°C.

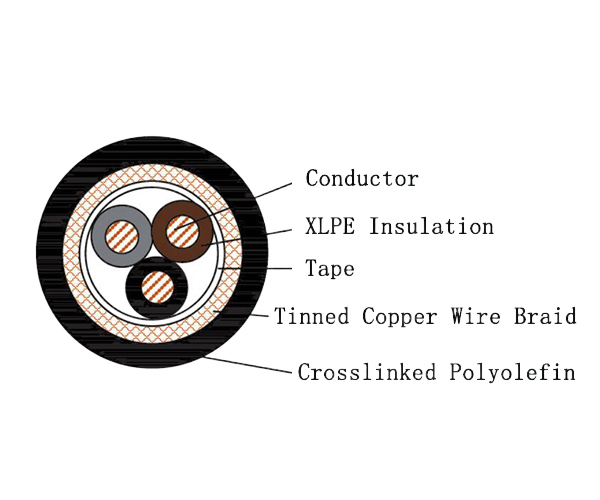

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Cross-Linked Polyethylene (XLPE) Insulated |

| Inner Sheath | \ | None (No separate inner sheath) |

| Armour | 8 | Braid of Tinned or Plain Copper Wires |

| Outer Sheath | 5 | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Flammability Class | SC | Halogen Free, Low Smoke, Flame Retardant |

| Sheath Colour | / | Standard Black (Other colours on request) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Cross-Linked Polyethylene (XLPE) |

| Armour | Braided Tinned/Plain Copper Wires |

| Outer Sheath | Cross-linked Polyolefin (SHF2) |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Halogen Content | IEC 60754-1 (Halogen Free) |

| Smoke Density | IEC 61034-2 (Low Smoke) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

This cable is designed and manufactured in compliance with the following international standards:

-

IEC 60092-350, 353: Electrical installations in ships – Design.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60332-1 & -3-22: Tests for flame retardancy.

-

IEC 60754-1: Test on gases evolved during combustion (Halogen Free).

-

IEC 61034-2: Measurement of smoke density (Low Smoke).

Typical Applications

-

Marine & Offshore: Power, lighting, and control circuits on ships and offshore platforms, particularly in areas where space is limited, environmental conditions are harsh (exposure to oils, chemicals, high ambient temperatures), and enhanced fire safety (LSZH) is required.

-

Industrial Plants: Robust power distribution in demanding industrial environments such as chemical processing, metallurgy, and power generation facilities, where the combination of a durable SHF2 sheath, flexible armor, and halogen-free safety is necessary.