Product Overview

The CJPFP90/NC is a robust fire resistant marine power cable engineered for critical circuits where maximum mechanical protection must coexist with guaranteed circuit integrity during fire emergencies. It features a Mica Glass Tape + XLPE composite insulation system for fire survival, combined with a Halogen-Free (LSZH) inner sheath and collective screen. Its defining characteristic is a high-strength galvanized steel wire braid armor, providing superior resistance to crushing, impact, and tensile stress. Designed without an outer sheath, this cable delivers the ultimate defense for essential power and control systems in the most demanding and physically hazardous locations.

Key Features & Benefits

-

Certified Fire Resistance: Complies with IEC 60331, ensuring continued electrical operation of emergency circuits (e.g., pumps, alarms) for a specified period under direct flame and mechanical shock, which is crucial for life safety.

-

High-Strength Mechanical Armor: A braided armor of galvanized steel wires offers exceptional protection against crushing, pulling, and impact, ideal for exposed runs or areas with severe physical hazards.

-

Fire-Survival Core Construction: The Mica Glass Tape layer over XLPE insulation creates a heat-resistant ceramic barrier that maintains insulation integrity at extreme temperatures, preventing circuit failure during a fire.

-

Superior Fire Safety: Meets IEC 60754 (Halogen Free) and IEC 61034 (Low Smoke), drastically reducing the emission of corrosive/toxic gases and smoke opacity to facilitate safer evacuation and protect equipment.

-

EMI Protection & Durability: The collective copper screen shields against electromagnetic interference, while the single, robust LSZH inner sheath provides essential environmental and chemical resistance.

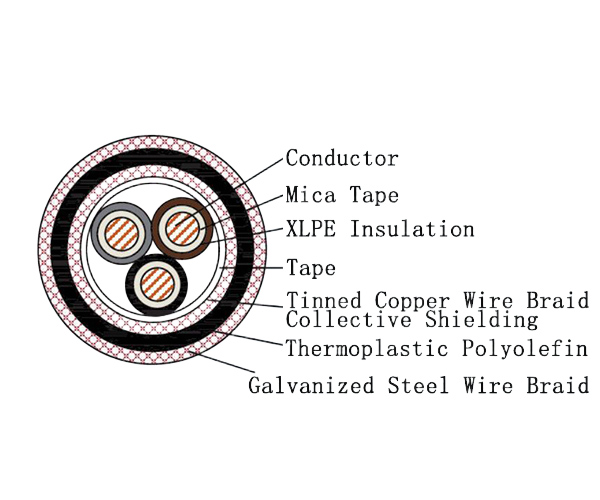

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Mica Glass Tape + XLPE Insulated |

| Inner Sheath | PF | Thermoplastic Polyolefin (SHF1) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 9 | Braid of Galvanized Steel Wires |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability Class | NC | Halogen Free, Low Smoke, Fire Resistant |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Mica Glass Tape + Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | Thermoplastic Polyolefin (SHF1) |

| Screen | Collective Copper Screen |

| Armour | Braided Galvanized Steel Wires |

| Fire Resistance | IEC 60331 |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 |

| Halogen Content | IEC 60754-1 (Halogen Free) |

| Smoke Density | IEC 61034-2 (Low Smoke) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

Manufactured to meet the highest international standards for safety, performance, and fire survival:

-

IEC 60092-350, 353: Electrical installations in ships – Design.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60331: Tests for fire resistant characteristics.

-

IEC 60332-1 & -3-22: Tests for flame retardancy.

-

IEC 60754-1: Test on gases evolved during combustion.

-

IEC 61034-2: Measurement of smoke density.

Typical Applications

-

Marine & Offshore: Critical emergency and power circuits in engine rooms, pump rooms, and along exposed decks on ships, tankers, and offshore platforms, where cables must withstand physical abuse while maintaining functionality in a fire (e.g., emergency generator feeds, fire pump power).

-

Heavy Industrial & Mining: Power supply for essential safety and process control systems in heavy industry, mining, and petrochemical plants, particularly in areas prone to mechanical damage (tunnels, shafts, heavy machinery zones) where circuit integrity during a fire is paramount.