Product Overview

The CJPFP96/NC represents the ultimate protection class for critical marine and industrial circuits, combining certified fire resistance with maximum mechanical and environmental defense. Designed for the most severe conditions, it integrates a Mica Glass Tape + XLPE fire-survival insulation system with a double-layer Halogen-Free (SHF1) sheath and a high-strength galvanized steel wire braid armor. This construction ensures not only circuit integrity during fire emergencies per IEC 60331 but also unparalleled durability against crushing, impact, abrasion, chemicals, and moisture, making it the definitive choice for safeguarding essential power and control systems in extreme-risk locations.

Key Features & Benefits

-

Certified Fire Resistance (IEC 60331): Guarantees continued operation of vital circuits (emergency lighting, alarms, shutdown systems) under direct flame and mechanical shock for a specified duration, crucial for life safety and asset protection.

-

Maximum Mechanical & Environmental Protection: A galvanized steel wire braid armor provides supreme crush and impact resistance, while the dual-layer SHF1 sheath offers an exceptional barrier against abrasion, oils, chemicals, and harsh environmental conditions.

-

Fire-Survival Core Technology: The Mica Glass Tape layer over XLPE insulation forms a robust, heat-resistant ceramic barrier at high temperatures, maintaining electrical insulation and preventing circuit failure during a fire.

-

Enhanced Fire Safety (LSZH): Complies with IEC 60754 (Halogen Free) and IEC 61034 (Low Smoke), significantly reducing the emission of corrosive/toxic gases and smoke density to facilitate safer evacuation and minimize secondary damage.

-

Comprehensive System Integrity: Combines circuit integrity (fire resistance), flame retardancy (IEC 60332), EMI shielding (collective screen), and extreme mechanical protection in one integrated cable solution.

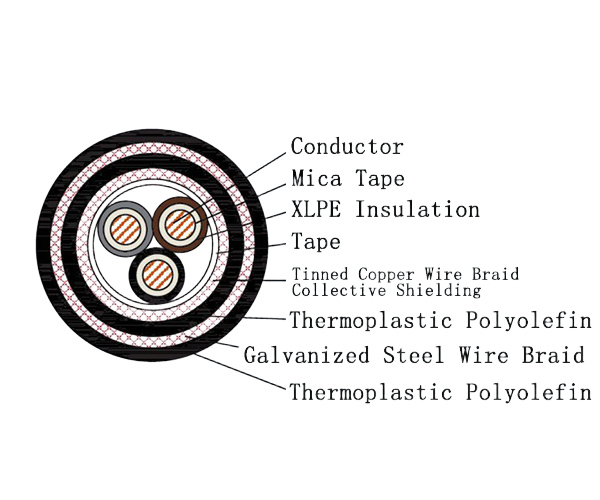

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Mica Glass Tape + XLPE Insulated |

| Inner Sheath | PF | Thermoplastic Polyolefin (SHF1) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 9 | Braid of Galvanized Steel Wires |

| Outer Sheath | 6 | Thermoplastic Polyolefin (SHF1) - Halogen Free, Low Smoke |

| Flammability Class | NC | Halogen Free, Low Smoke, Fire Resistant |

| Sheath Colour | / | Standard Black (Other colours on request) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Mica Glass Tape + Cross-Linked Polyethylene (XLPE) |

| Inner & Outer Sheath | Thermoplastic Polyolefin (SHF1) |

| Screen | Collective Copper Screen |

| Armour | Braided Galvanized Steel Wires |

| Fire Resistance | IEC 60331 |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Halogen Content | IEC 60754-1 (Halogen Free) |

| Smoke Density | IEC 61034-2 (Low Smoke) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

This cable is manufactured to the highest international standards for fire safety, marine application, and material performance:

-

IEC 60092-350, 353: Electrical installations in ships – Design.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60331: Tests for fire resistant characteristics.

-

IEC 60332-1 & -3-22: Tests for flame retardancy.

-

IEC 60754-1: Test on gases evolved during combustion (Halogen Free).

-

IEC 61034-2: Measurement of smoke density (Low Smoke).

Typical Applications

-

Marine & Offshore: Critical and essential circuits on passenger ships, naval vessels, and offshore oil & gas platforms, especially in exposed, high-risk, or mechanically demanding areas such as engine rooms, pump rooms, open decks, and hazardous zones, powering emergency generators, fire pumps, alarm, and communication systems.

-

Critical Infrastructure & Heavy Industry: Life-safety and backup power circuits in extreme environments such as nuclear/thermal power plants, petrochemical refineries, underground mining, tunnels, metro systems, and large industrial complexes where both fire survival and robust physical protection are non-negotiable requirements.