Product Overview

The CJPFP86/NC is an enhanced, double-sheathed fire resistant marine cable designed to provide maximum circuit integrity and physical protection in critical emergency scenarios. It combines the essential fire-survival capability of Mica Glass Tape + XLPE composite insulation with the superior mechanical and environmental defense of a dual-layer Halogen-Free (SHF1) sheath. Protected by a flexible tinned copper braid armor and a collective screen, this cable ensures uninterrupted power to vital systems during fire events while offering exceptional durability against abrasion, chemicals, and harsh conditions for the most demanding marine and industrial safety applications.

Key Features & Benefits

-

Certified Circuit Integrity: Complies with IEC 60331 for fire resistance, ensuring continued operation of emergency circuits (lighting, alarms, pumps) for a specified duration under direct flame and impact.

-

Fire-Survival Core Construction: Utilizes a Mica Glass Tape layer over XLPE insulation to form a robust ceramic barrier under heat, preventing short-circuits and maintaining electrical function during a fire.

-

Enhanced Double-Layer Protection: Features both an inner and outer sheath made of Thermoplastic Polyolefin (SHF1), providing superior resistance to mechanical damage, moisture, oils, and chemicals compared to single-sheathed designs.

-

Superior Fire Safety Profile: Meets IEC 60754 (Halogen Free) and IEC 61034 (Low Smoke), minimizing corrosive gas emission and smoke density to facilitate safer evacuation and reduce secondary damage.

-

Flexible & Durable Armor: A braid of tinned copper wires offers excellent flexibility for installation, reliable grounding, and corrosion resistance in marine environments.

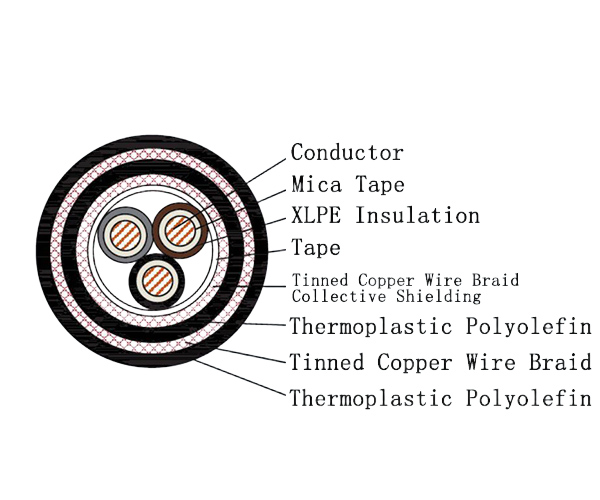

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Mica Glass Tape + XLPE Insulated |

| Inner Sheath | PF | Thermoplastic Polyolefin (SHF1) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 8 | Braid of Tinned or Plain Copper Wires |

| Outer Sheath | 6 | Thermoplastic Polyolefin (SHF1) - Halogen Free, Low Smoke |

| Flammability Class | NC | Halogen Free, Low Smoke, Fire Resistant |

| Sheath Colour | / | Standard Black (Other colours on request) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Mica Glass Tape + Cross-Linked Polyethylene (XLPE) |

| Inner & Outer Sheath | Thermoplastic Polyolefin (SHF1) |

| Screen | Collective Copper Screen |

| Armour | Braided Tinned/Plain Copper Wires |

| Fire Resistance | IEC 60331 |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Halogen Content | IEC 60754-1 (Halogen Free) |

| Smoke Density | IEC 61034-2 (Low Smoke) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

This cable is manufactured to the highest international standards for safety and performance:

-

IEC 60092-350, 353: Electrical installations in ships – Design.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60331: Tests for fire resistant characteristics.

-

IEC 60332-1 & -3-22: Tests for flame retardancy.

-

IEC 60754-1: Test on gases evolved during combustion.

-

IEC 61034-2: Measurement of smoke density.

Typical Applications

-

Marine & Offshore: Critical emergency circuits on passenger ships, ferries, and offshore platforms, including emergency lighting, fire alarm systems, sprinkler pumps, communication systems, and engine room shutdown controls where both circuit integrity and enhanced cable durability are required.

-

Critical Infrastructure: Power supply for life-safety and essential operational systems in high-risk land-based facilities such as power plants (nuclear, thermal), petrochemical complexes, tunnels, metro systems, and high-rise buildings, particularly in areas exposed to physical wear.