Product Overview

F6 AICI Optical Fiber Cables provide fire-resistant, flame-retardant performance with low smoke zero halogen properties for critical instrumentation, data, and communication systems in marine and offshore environments. Featuring galvanized steel wire braid armor and tight buffered construction, these cables ensure reliable operation in demanding conditions while meeting stringent fire safety standards.

Key Features

-

Fire Resistant Construction: Meets IEC 60331-25 for circuit integrity during fire

-

Enhanced Safety: Low smoke zero halogen (LSZH) materials

-

Robust Protection: Galvanized steel wire braid armor

-

Multiple Fiber Options: Supports OS1, OS2, OM1, OM2, and OM3 classifications

-

Wide Temperature Range: -40℃ to +70℃ operation

-

UV Resistant: UV-stabilized outer sheath for durability

Applications

-

Marine instrumentation systems

-

Offshore data communication networks

-

Shipboard control and monitoring systems

-

Critical communication infrastructure

-

Fire-safe data transmission applications

-

Offshore platform communication systems

Standards Compliance

-

IEC 60794 - Optical fibre cable standards

-

IEC 60811-2-1 - Cable material tests

-

IEC 60331-25 - Fire resistance tests

-

IEC 60332-3-24 - Flame spread tests

-

IEC 60332-3-22 - Flame spread for bunched cables

-

IEC 60754-1,2 - Halogen gas emission tests

-

IEC 61034-1,2 - Smoke density measurement

-

NEK 606:2004 - Offshore and marine cable standard

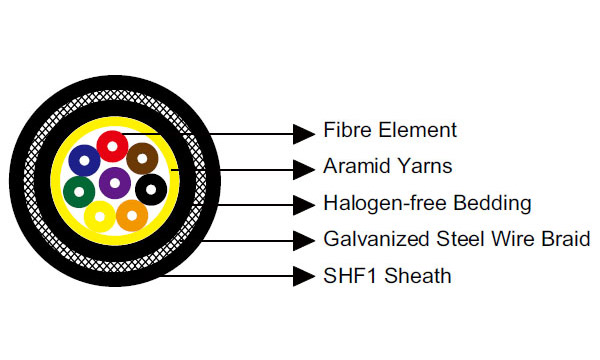

Construction Details

-

Fibre Element: Tight buffered fibres

-

Central Strength Element: Fibre reinforced plastic (FRP) and/or aramid yarns

-

Bedding: Halogen free flame retardant thermoplastic compound

-

Armour: Galvanized steel wire braid

-

Outer Sheath: Halogen free flame retardant, UV-stabilized thermoplastic compound (SHF1)

Electrical Characteristics

| Parameter | 9/125 (G652.D) | 50/125 (G651) OM2 | 50/125 (G651) OM3 | 62.5/125 OM1 |

|---|---|---|---|---|

| ITU-T Type | G652.D | G651 | G651 | – |

| IEC 11801 Class | OS1 & OS2 | OM2 | OM3 | OM1 |

| Core Diameter (μm) | 8.7±0.4 | 50±3.0 | 50±3.0 | 62.5±3.0 |

| Cladding Diameter (μm) | 125±1.0 | 125±2.0 | 125±2.0 | 125±2.0 |

| Coating Diameter (μm) | 245±10 | 245±10 | 245±10 | 245±10 |

Maximum Attenuation

| Wavelength | 9/125 | 50/125 OM2 | 50/125 OM3 | 62.5/125 |

|---|---|---|---|---|

| 850 nm (dB/km) | – | 3.0 | 3.0 | 3.5 |

| 1300 nm (dB/km) | – | 1.5 | 1.0 | 1.5 |

| 1310 nm (dB/km) | 0.36 | – | – | – |

| 1550 nm (dB/km) | 0.22 | – | – | – |

Bandwidth & Dispersion Characteristics

| Parameter | 9/125 | 50/125 OM2 | 50/125 OM3 | 62.5/125 |

|---|---|---|---|---|

| Bandwidth @850 nm (MHz.km) | – | 500 | 1500 | 200 |

| Bandwidth @1300 nm (MHz.km) | – | 500 | 500 | 600 |

| Chromatic Dispersion 1285-1330 nm (ps/nm·km) | 2.8 | – | – | – |

| Chromatic Dispersion 1550 nm (ps/nm·km) | 18 | – | – | – |

| Zero Dispersion Wavelength (nm) | 1300~1324 | – | – | – |

Mechanical & Thermal Properties

-

Bending Radius: 20 × OD (during installation); 10 × OD (fixed installed)

-

Temperature Range: -40℃ to +70℃

-

Installation: Suitable for harsh marine environments

-

Durability: Armoured construction with UV stabilization

Dimensions and Weight

| Number of Fibers | Secondary Coating (mm) | Nominal Overall Diameter (mm) | Nominal Weight (kg/km) |

|---|---|---|---|

| 2 | 0.9 | 7.8 | 100 |

| 4 | 0.9 | 8.2 | 110 |

| 8 | 0.9 | 9.4 | 125 |

| 12 | 0.9 | 10.3 | 145 |

| 24 | 0.9 | 12.0 | 185 |