0.6/1kV JIS C 3410 Shielded Shipboard Cables: [FA-] SPYCS, SPYCBS, DPYCS, TPYCS, FPYCS[FA-] SPYCYS, SPYCBYS, DPYCYS, TPYCYS, FPYCYS

Product Overview

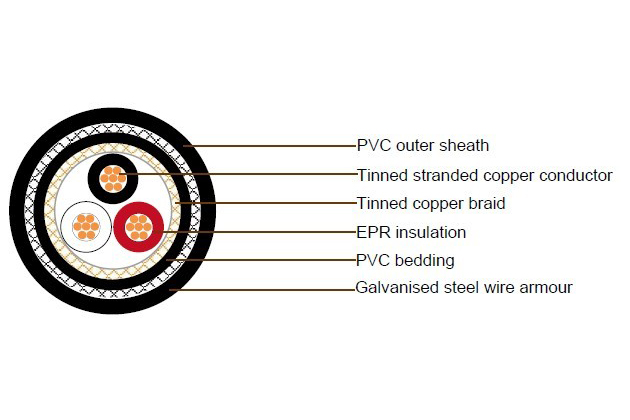

JIS C 3410 compliant 0.6/1kV shipboard power cables featuring overall tinned copper braid shield for comprehensive EMI protection. Available in single-core to multi-core configurations with EPR insulation and optional galvanized steel or copper alloy wire armor.

Technical Standards & Certifications

-

Primary Standard: JIS C 3410-1999

-

Fire Safety: IEC 60332-1

-

Flame Retardant: IEC 60332-3 Cat.A (for FA-type)

-

Rated Voltage: 0.6/1kV

Cable Construction & Materials

[FA-] SPYCS, SPYCBS, DPYCS, TPYCS, FPYCS Construction

| Component | Code | Specification |

|---|---|---|

| Conductor | S(D,T) | Tinned annealed stranded copper, class 2 per IEC 60228 |

| Insulation | P | 85°C EPR as per JIS C 3410 |

| Cabling | Insulated conductors cabled with flame retardant fillers | |

| Overall Shield | S | Tinned copper wire braid |

| Bedding | Y | PVC as per JIS C 3410 |

| Armor | C(CB) | Galvanized steel wire braid (-C TYPE) or copper alloy wire braid (-CB TYPE) |

| Sheath | Y | PVC as per JIS C 3410 |

Core Identification & Color Coding

-

1 Core: Black

-

2 Core: Black, White

-

3 Core: Black, White, Red

-

Outer Sheath Color: Black

Technical Specifications

Single-Core Cables (SPYCS, SPYCBS, SPYCYS, SPYCBYS)

| Conductor Size mm² | Conductor Construction | Shield Wire Dia mm | Bedding Thickness mm | Armor Wire Dia mm | Nom. Overall Dia mm | Cable Weight kg/km |

|---|---|---|---|---|---|---|

| SPYCS/SPYCBS | ||||||

| 1.5 | 7/0.53 | 0.12 | 1.0 | 0.3 | 8.0 | 110 |

| 2.5 | 7/0.67 | 0.12 | 1.0 | 0.3 | 8.5 | 130 |

| 4 | 7/0.85 | 0.12 | 1.0 | 0.3 | 9.1 | 150 |

| 6 | 7/1.04 | 0.14 | 1.0 | 0.3 | 9.7 | 180 |

| 10 | 7/1.35 | 0.14 | 1.1 | 0.3 | 11.0 | 240 |

| 16 | 7/1.70 | 0.14 | 1.1 | 0.3 | 12.0 | 320 |

| 25 | 7/2.14 | 0.14 | 1.2 | 0.3 | 13.9 | 450 |

| 35 | 7/2.52 | 0.16 | 1.2 | 0.3 | 15.2 | 550 |

| 50 | 19/1.78 | 0.16 | 1.3 | 0.3 | 17.3 | 710 |

| 70 | 19/2.14 | 0.16 | 1.4 | 0.3 | 19.7 | 980 |

| 95 | 19/2.52 | 0.16 | 1.5 | 0.3 | 21.9 | 1280 |

| 120 | 37/2.03 | 0.18 | 1.6 | 0.3 | 23.8 | 1570 |

| 150 | 37/2.25 | 0.18 | 1.6 | 0.3 | 25.8 | 1900 |

| 185 | 37/2.52 | 0.18 | 1.7 | 0.3 | 28.2 | 2310 |

| 240 | 61/2.25 | 0.20 | 1.8 | 0.4 | 32.2 | 2980 |

| 300 | 61/2.52 | 0.20 | 2.0 | 0.4 | 35.5 | 3750 |

Two-Core Cables (DPYCS, DPYCYS)

| Conductor Size mm² | Conductor Construction | Shield Wire Dia mm | Bedding Thickness mm | Armor Wire Dia mm | Nom. Overall Dia mm | Cable Weight kg/km |

|---|---|---|---|---|---|---|

| DPYCS | ||||||

| 1.5 | 7/0.53 | 0.14 | 1.2 | 0.3 | 12.6 | 265 |

| 2.5 | 7/0.67 | 0.14 | 1.2 | 0.3 | 13.5 | 310 |

| 4 | 7/0.85 | 0.16 | 1.2 | 0.3 | 14.7 | 380 |

| 6 | 7/1.04 | 0.16 | 1.3 | 0.3 | 15.9 | 460 |

| 10 | 7/1.35 | 0.16 | 1.3 | 0.3 | 18.0 | 610 |

| 16 | 7/1.70 | 0.16 | 1.4 | 0.3 | 20.2 | 790 |

| 25 | 7/2.14 | 0.18 | 1.6 | 0.3 | 24.1 | 1100 |

| 35 | 7/2.52 | 0.18 | 1.7 | 0.3 | 26.6 | 1400 |

| 50 | 19/1.78 | 0.18 | 1.8 | 0.3 | 30.6 | 1800 |

| 70 | 19/2.14 | 0.20 | 2.0 | 0.4 | 36.1 | 2640 |

| 95 | 19/2.52 | 0.26 | 2.2 | 0.4 | 40.7 | 3410 |

| 120 | 37/2.03 | 0.26 | 2.3 | 0.4 | 44.2 | 3900 |

Three-Core Cables (TPYCS, TPYCYS)

| Conductor Size mm² | Conductor Construction | Shield Wire Dia mm | Bedding Thickness mm | Armor Wire Dia mm | Nom. Overall Dia mm | Cable Weight kg/km |

|---|---|---|---|---|---|---|

| TPYCS | ||||||

| 1.5 | 7/0.53 | 0.14 | 1.2 | 0.3 | 13.2 | 305 |

| 2.5 | 7/0.67 | 0.14 | 1.2 | 0.3 | 14.2 | 360 |

| 4 | 7/0.85 | 0.16 | 1.3 | 0.3 | 15.7 | 455 |

| 6 | 7/1.04 | 0.16 | 1.3 | 0.3 | 16.8 | 530 |

| 10 | 7/1.35 | 0.16 | 1.4 | 0.3 | 19.0 | 730 |

| 16 | 7/1.70 | 0.16 | 1.5 | 0.3 | 21.4 | 990 |

| 25 | 7/2.14 | 0.18 | 1.6 | 0.3 | 25.6 | 1400 |

| 35 | 7/2.52 | 0.18 | 1.7 | 0.3 | 28.2 | 1850 |

| 50 | 19/1.78 | 0.20 | 1.9 | 0.3 | 32.7 | 2450 |

| 70 | 19/2.14 | 0.26 | 2.1 | 0.4 | 38.7 | 3350 |

| 95 | 19/2.52 | 0.26 | 2.3 | 0.4 | 43.4 | 4390 |

| 120 | 37/2.03 | 0.26 | 2.4 | 0.4 | 47.1 | 5350 |

| 150 | 37/2.25 | 0.26 | 2.6 | 0.4 | 51.8 | 6100 |

| 185 | 37/2.52 | 0.26 | 2.8 | 0.4 | 57.0 | 7530 |

Four-Core Cables (FPYCS, FPYCYS)

| Conductor Size mm² | Conductor Construction | Shield Wire Dia mm | Bedding Thickness mm | Armor Wire Dia mm | Nom. Overall Dia mm | Cable Weight kg/km |

|---|---|---|---|---|---|---|

| FPYCS | ||||||

| 1.5 | 7/0.53 | 0.14 | 1.2 | 0.3 | 14.0 | 400 |

| 2.5 | 7/0.67 | 0.16 | 1.2 | 0.3 | 15.3 | 480 |

| 4 | 7/0.85 | 0.16 | 1.3 | 0.3 | 16.7 | 600 |

| 6 | 7/1.04 | 0.16 | 1.4 | 0.3 | 18.3 | 740 |

| 10 | 7/1.35 | 0.16 | 1.4 | 0.3 | 20.7 | 1030 |

| 16 | 7/1.70 | 0.18 | 1.5 | 0.3 | 23.6 | 1350 |

| 25 | 7/2.14 | 0.18 | 1.7 | 0.3 | 28.1 | 1950 |

| 35 | 7/2.52 | 0.18 | 1.8 | 0.3 | 31.1 | 2540 |

| 50 | 19/1.78 | 0.20 | 2.0 | 0.4 | 36.6 | 3480 |

| 70 | 19/2.14 | 0.26 | 2.2 | 0.4 | 41.6 | 4750 |

| 95 | 19/2.52 | 0.26 | 2.4 | 0.4 | 48.0 | 6280 |

| 120 | 37/2.03 | 0.26 | 2.6 | 0.4 | 52.1 | 7590 |

| 150 | 37/2.25 | 0.26 | 2.8 | 0.4 | 57.4 | 9150 |

| 185 | 37/2.52 | 0.26 | 3.0 | 0.4 | 63.2 | 11150 |

Covered Armor Variants (SPYCYS, SPYCBYS, DPYCYS, TPYCYS, FPYCYS)

-

Additional covering over armor wire (0.8-2.2mm thickness)

-

Increased overall diameter by approximately 1.9-2.5mm

-

Higher weight due to additional covering material

-

Enhanced mechanical protection and corrosion resistance

Features & Benefits

-

Overall Shield Design: Tinned copper wire braid provides comprehensive EMI protection

-

Dual Armor Options: Galvanized steel wire or copper alloy wire braid

-

High Temperature Rating: 85°C EPR insulation for reliable thermal performance

-

Flame Retardant: Compliant with IEC 60332-1 and IEC 60332-3 Cat.A standards

-

Marine Grade: Tinned copper conductors and corrosion-resistant materials

-

Multiple Configurations: 1 to 4 core options for various power applications

-

Comprehensive Range: Conductor sizes from 1.5mm² to 300mm²

Application Areas

-

Shipboard power distribution systems requiring EMI protection

-

Marine equipment with sensitive electronic controls

-

Naval vessel main power circuits

-

Offshore platform power distribution

-

Critical marine electrical systems requiring enhanced shielding

*Note: All specifications are in accordance with JIS C 3410-1999 standards. Cable parameters may vary within manufacturing tolerances. These shielded power cables are designed for marine applications requiring comprehensive electromagnetic interference protection with their overall braid shield construction.*