JIS C 3410 Shipboard Cables | FA-TTYS TTYCS TTYCYS TTPYS TTPYCS TTPYCYS

Product Overview

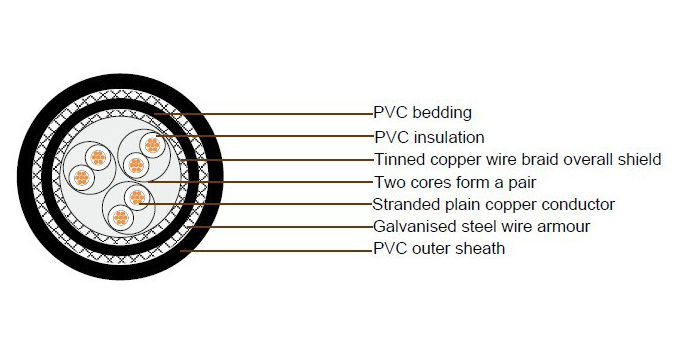

JIS C 3410 compliant shipboard cables with overall tinned copper braid shield, designed for reliable communication and control systems in marine environments. Available in multiple configurations with PVC or EPR insulation and optional armored protection.

Technical Standards & Certifications

-

Primary Standard: JIS C 3410-1999

-

Fire Safety: IEC 60332-1

-

Flame Retardant: IEC 60332-3 Cat.A (for FA-type)

Cable Construction & Types

[FA-] TTYS, TTYCS, TTYCYS Construction

| Component | Code | Specification |

|---|---|---|

| Conductor | TT | Tinned annealed stranded copper (TTY-type), class 2 per IEC 60228 |

| Insulation | 60°C PVC (TTY-type) as per JIS C 3410 | |

| Twisting | Two insulated cores twisted together to form a pair | |

| Cabling | Twisted pairs cabled with flame retardant fillers | |

| Overall Shield | S | Tinned copper wire braid |

| Bedding | Y | PVC as per JIS C 3410 |

| Armor | C | Galvanized steel wire braid |

| Sheath | Y | PVC as per JIS C 3410 |

[FA-] TTPYS, TTPYCS, TTPYCYS Construction

| Component | Code | Specification |

|---|---|---|

| Conductor | TTP | Tinned annealed stranded copper (TTPY-type), class 2 per IEC 60228 |

| Insulation | 85°C EPR (TTPY-type) as per JIS C 3410 | |

| Twisting | Two insulated cores twisted together to form a pair | |

| Cabling | Twisted pairs cabled with flame retardant fillers | |

| Overall Shield | S | Tinned copper wire braid |

| Bedding | Y | PVC as per JIS C 3410 |

| Armor | C | Galvanized steel wire braid |

| Sheath | Y | PVC as per JIS C 3410 |

Core Identification & Color Coding

-

Printed Identification: Pair number and alphabet letter on white insulation

-

Example: 4P: (1A, 1B), (2A, 2B), (3A, 3B), (4A, 4B)

-

Single Pair/Triad/Quad: Black number on white insulation (1T, 1Q)

-

Outer Sheath Color: Black

Technical Specifications

(FA-) TTYS, TTPYS Specifications

| No. of Pairs | Conductor Size mm² | Conductor Construction | Insulation Thickness mm | Shield Wire Dia mm | Bedding Thickness mm | Nom. Overall Dia mm | Tolerance mm | Cable Weight kg/km |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 8.8 | 0.4 | 120 |

| 1T | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 9.3 | 0.4 | 140 |

| 1Q | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 10.0 | 0.5 | 160 |

| 2 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 13.0 | 0.6 | 200 |

| 4 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 15.0 | 0.7 | 300 |

| 7 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 17.7 | 0.8 | 420 |

| 10 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 22.8 | 1.0 | 640 |

| 14 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 24.4 | 1.0 | 770 |

| 19 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 27.5 | 1.2 | 970 |

| 24 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.20 | 33.1 | 1.4 | 1290 |

| 30 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 35.5 | 1.5 | 1620 |

| 37 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 38.4 | 1.6 | 1890 |

| 48 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 44.3 | 1.7 | 2420 |

(FA-) TTYCS, TTPYCS Specifications

| No. of Pairs | Conductor Size mm² | Conductor Construction | Steel Wire Dia mm | Nom. Overall Dia mm | Tolerance mm | Cable Weight kg/km |

|---|---|---|---|---|---|---|

| 1 | 0.75 | 7/0.37 | 0.3 | 10.1 | 0.4 | 180 |

| 1T | 0.75 | 7/0.37 | 0.3 | 10.6 | 0.4 | 205 |

| 1Q | 0.75 | 7/0.37 | 0.3 | 11.3 | 0.5 | 230 |

| 2 | 0.75 | 7/0.37 | 0.3 | 14.6 | 0.7 | 230 |

| 4 | 0.75 | 7/0.37 | 0.3 | 16.3 | 0.7 | 405 |

| 7 | 0.75 | 7/0.37 | 0.3 | 19.0 | 0.7 | 545 |

| 10 | 0.75 | 7/0.37 | 0.3 | 24.1 | 1.0 | 800 |

| 14 | 0.75 | 7/0.37 | 0.3 | 25.7 | 1.0 | 935 |

| 19 | 0.75 | 7/0.37 | 0.3 | 28.8 | 1.2 | 1160 |

| 24 | 0.75 | 7/0.37 | 0.4 | 34.9 | 1.4 | 1600 |

| 30 | 0.75 | 7/0.37 | 0.4 | 37.3 | 1.5 | 1950 |

| 37 | 0.75 | 7/0.37 | 0.4 | 40.2 | 1.6 | 2250 |

| 48 | 0.75 | 7/0.37 | 0.4 | 46.1 | 1.7 | 2830 |

(FA-) TTYCYS, TTPYCYS Specifications

| No. of Pairs | Conductor Size mm² | Conductor Construction | Steel Wire Dia mm | Covering Thickness mm | Nom. Overall Dia mm | Tolerance mm | Cable Weight kg/km |

|---|---|---|---|---|---|---|---|

| 1 | 0.75 | 7/0.37 | 0.3 | 0.9 | 12.1 | 0.5 | 230 |

| 1T | 0.75 | 7/0.37 | 0.3 | 0.9 | 12.6 | 0.5 | 255 |

| 1Q | 0.75 | 7/0.37 | 0.3 | 0.9 | 13.3 | 0.5 | 285 |

| 2 | 0.75 | 7/0.37 | 0.3 | 1.0 | 16.7 | 0.7 | 285 |

| 4 | 0.75 | 7/0.37 | 0.3 | 1.0 | 18.5 | 0.7 | 490 |

| 7 | 0.75 | 7/0.37 | 0.3 | 1.1 | 21.4 | 0.9 | 650 |

| 10 | 0.75 | 7/0.37 | 0.3 | 1.2 | 26.7 | 1.1 | 945 |

| 14 | 0.75 | 7/0.37 | 0.3 | 1.2 | 28.3 | 1.1 | 1090 |

| 19 | 0.75 | 7/0.37 | 0.3 | 1.3 | 31.6 | 1.3 | 1340 |

| 24 | 0.75 | 7/0.37 | 0.4 | 1.5 | 38.3 | 1.5 | 1860 |

| 30 | 0.75 | 7/0.37 | 0.4 | 1.5 | 40.7 | 1.6 | 2230 |

| 37 | 0.75 | 7/0.37 | 0.4 | 1.6 | 43.8 | 1.7 | 2570 |

| 48 | 0.75 | 7/0.37 | 0.4 | 1.8 | 50.1 | 1.8 | 3240 |

Features & Benefits

-

JIS C 3410 Compliant: Meets Japanese Industrial Standards for shipboard use

-

Overall Shield: Tinned copper wire braid for comprehensive EMI protection

-

Multiple Configurations: Single pair, triad, quad and multi-pair options

-

Temperature Options: 60°C PVC or 85°C EPR insulation

-

Flame Retardant: IEC 60332-1 and IEC 60332-3 Cat.A compliant

-

Armored Protection: Galvanized steel wire braid for mechanical durability

-

Marine Grade: Corrosion-resistant materials for harsh marine environments

Application Areas

-

Shipboard communication and control systems

-

Marine instrumentation and automation

-

Naval vessel electrical systems

-

Offshore platform communications

-

Critical marine control applications

*Note: All specifications are in accordance with JIS C 3410-1999 standards. Cable parameters may vary within manufacturing tolerances. Consult technical datasheets for specific application requirements and conductor size availability.*