Product Overview

NSHTOEU Rubber Flexible Cable is specifically engineered for hoisting and hauling systems requiring positive cable guidance under high mechanical loads. Designed for applications involving frequent reeling and unreeling operations, this cable delivers exceptional performance in demanding environments including dry and damp areas, outdoor locations, and explosion-risk zones.

Key Features & Benefits

-

Superior Mechanical Durability: Withstands high mechanical loads in hoisting and hauling applications

-

Exceptional Flexibility: Specifically designed for frequent reeling/unreeling and deflection over pulleys

-

Wide Temperature Range: Suitable for fixed installations from -40°C to +60°C and flexed applications from -25°C to +60°C

-

Torsion-Free Operation: Special design requires torsion-free connection for optimal performance

-

Environmental Resistance: Performs reliably in dry, damp, outdoor, and explosion-risk environments

-

Optimized Bending Performance: Maintains integrity when deflected over cable tenders and pulleys

Applications

Specialized hoisting and hauling applications:

-

Hoisting Systems: Positive cable guidance systems in lifting applications

-

Hauling Equipment: Heavy-duty hauling systems requiring flexible cable solutions

-

Reeling Operations: Applications involving frequent reeling and unreeling cycles

-

Pulley Systems: Equipment with constant deflection over cable tenders and pulleys

-

Explosion-Risk Areas: Hazardous environments requiring certified cable solutions

-

Outdoor Industrial Applications: External hoisting and hauling operations

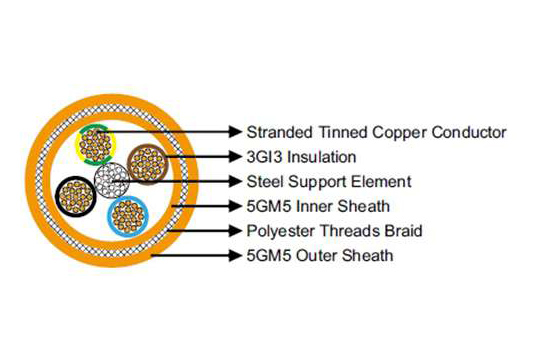

Construction

Advanced Flexible Construction:

-

Conductor: Flexible Class 5 tinned copper conductor (BS EN 60228)

-

Insulation: Rubber compound Type 3GI3 (VDE 0207 part 20)

-

Filler: EPR (Ethylene Propylene Rubber) Type 3GI3 on textile polyester support

-

Bedding: Rubber compound Type GM1b (VDE 0207 part 21)

-

Braiding: Polyester braid for additional protection

-

Sheath: Rubber compound Type 5GM3 (VDE 0207 part 21)

Characteristics

Electrical & Mechanical Performance:

-

Voltage Rating (Uo/U): 600/1000V

-

Temperature Rating:

-

Fixed: -40°C to +60°C

-

Flexed: -25°C to +60°C

-

-

Minimum Bending Radius:

-

Fixed: 4 × overall diameter

-

Flexed: 5 × overall diameter

-

Identification & Coloring:

-

NSHTÖU-J:

-

4 core: Green/Yellow, Black, Grey, Brown

-

5 core: Green/Yellow, Black, Blue, Brown, Grey

-

-

NSHTÖU-O:

-

4 core: Grey, Brown, Black, Blue

-

5 core: Grey, Brown, Black, Blue, Black

-

-

Sheath Color: Black

Specifications

Detailed Technical Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 4×16 (6 kN) | 27.5 | 31.5 | 1500 |

| 4×35 (12 kN) | 37.5 | 42.0 | 2920 |

| 4×50 (12 kN) | 43.0 | 48.0 | 3970 |

| 4×50 (30 kN) | 42.0 | 44.0 | 3660 |

| 4×70 (20 kN) | 47.0 | 52.0 | 5530 |

| 4×95 (50 kN) | 53.0 | 58.0 | 6500 |

Installation Guidelines

Critical Installation Requirements:

-

Torsion-Free Connection: Cables must be connected completely free of torsion

-

Tensile Stress Relief: Tensile stresses at cable ends must be suitably relieved and conducted to internal tensile elements

-

Pulley Configuration: Stationary pulleys bearing two turns of cable are recommended

-

Layout Considerations: S-shaped turns should be avoided during laying and within cable guidance systems

Key Advantages

-

Proven Reliability: Specifically designed for high-stress hoisting and hauling applications

-

Enhanced Safety: Suitable for explosion-risk areas and demanding industrial environments

-

Optimized Flexibility: Maintains performance in frequent reeling and pulley deflection applications

-

Comprehensive Standards Compliance: Meets VDE 0207 and BS EN 60228 standards

-

Multiple Configuration Options: Available in various core arrangements and tensile strength ratings

-

Professional Installation Support: Clear guidelines ensure proper installation and long-term reliability