Product Overview

NTMTWOEU Underground Mine Hoisting Cable 600/1000V is specifically engineered for suspended cable applications in user-operated mine hoists (lifts) with telephonic connections in underground mining operations. Featuring a robust construction with central steel support and anti-torsion braid, this cable ensures reliable performance in critical mine hoisting systems where intrinsic safety and communication capabilities are paramount.

Key Features & Benefits

-

Intrinsically Safe Design: Specifically designed for intrinsically safe control of user-operated mine hoists

-

Enhanced Communication Capability: Integrated telephonic connection for underground mine communication systems

-

Superior Mechanical Protection: Central steel support element provides structural integrity and tensile strength

-

Anti-Torsion Design: Textile braid prevents cable twisting during operation and installation

-

Durable Outer Protection: PCP rubber sheath offers excellent resistance to mining environmental conditions

-

Flexible Conductors: Class 5 tinned copper conductors ensure optimal flexibility and conductivity

Applications

Specialized underground mining hoisting applications:

-

Mine Hoist Systems: Suspended cable for user-operated mine lifts and hoists

-

Underground Mining Operations: Critical hoisting applications in underground mines

-

Intrinsically Safe Control: Systems requiring intrinsic safety certification

-

Mine Communication: Hoists with integrated telephonic connection capabilities

-

Suspended Cable Applications: Overhead cable systems for mine transportation

-

Safety-Critical Systems: Applications where reliable hoisting operation is essential

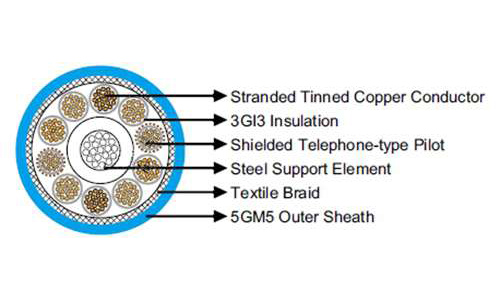

Construction

Robust Mining-Grade Construction:

-

Conductors: Flexible stranded tinned copper conductor, class 5 (DIN VDE 0295)

-

Insulation: EPR type 3GI3

-

Support Element: Central steel support element for structural integrity

-

Anti-torsion Braid: Textile braid to prevent cable twisting

-

Outer Sheath: PCP rubber type 5GM5 for environmental protection

Standards Compliance

Applied Standards:

-

VDE 0250 Part 813

Specifications

Detailed Technical Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 8×2.5ST+2x1FM(C) | 21.7 | 23.7 | 800 |

| 8×2.5ST+10x (2x1FM)C | 34.0 | 37.5 | 1450 |

| 14×2.5ST+6x1FM(C) | 27.0 | 31.0 | 1200 |

| 18×2.5ST+6x1FM(C) | 38.0 | 42.0 | 1800 |

| 19×1.5(C)ST+6x (2x1FM)C | 35.1 | 38.1 | 2145 |

Key Advantages

-

Proven Safety Performance: Designed specifically for intrinsically safe mine hoist applications

-

Reliable Communication: Integrated telephonic connection capabilities for underground operations

-

Enhanced Durability: Central steel support and anti-torsion design ensure long service life

-

Mining-Grade Materials: PCP rubber sheath withstands harsh underground environments

-

Multiple Configuration Options: Various core arrangements to suit different hoisting system requirements

-

Industry Compliance: Meets VDE 0250 Part 813 standards for mining cable applications

-

Optimized Performance: Combines electrical reliability with mechanical strength for critical hoisting operations