Product Overview

NSSHKCGEOEU Coal Cutting Machine Cable is engineered for the most demanding mining applications requiring exceptional mechanical durability and flexibility. Specifically designed for coal-cutting machines and mobile mining equipment, this cable withstands extreme bending stresses, high tensile loads, and impact forces while providing reliable power transmission in underground mining operations.

Key Features & Benefits

-

Exceptional Mechanical Strength: Withstands extreme bending stresses, high tensile loads, impact, and crushing forces

-

Advanced Safety Monitoring: Phase-concentric monitoring shield and earth conductor enable continuous insulation fault detection

-

Superior Flexibility: Torsion and tensile-stress-resistant armour allows operation via guide pulleys and reeling systems

-

Clamping Damage Detection: Meets DIN VDE 0472 Part 818 standards for detecting clamping-induced damage as earth faults

-

Enhanced Durability: Abrasion and tear-resistant outer sheath with oil resistance and flame retardant properties

-

Multiple Configurations: Available with 2, 3, or 6 pilot cores to suit various application requirements

Applications

Extreme-duty mining applications:

-

Coal-Cutting Machines: Primary connection for coal cutting equipment in underground mines

-

Mobile Mining Equipment: Connection of mobile machines under extremely high mechanical loads

-

Free Trailing Applications: Applications requiring cable movement without fixed installation

-

Guide Pulley Systems: Operation via cable guidance pulleys in mining operations

-

LHD Reeling Systems: Reeling cable applications on Load-Haul-Dump machines

-

High-Stress Environments: Mining situations with extreme bending and tensile stresses

Construction

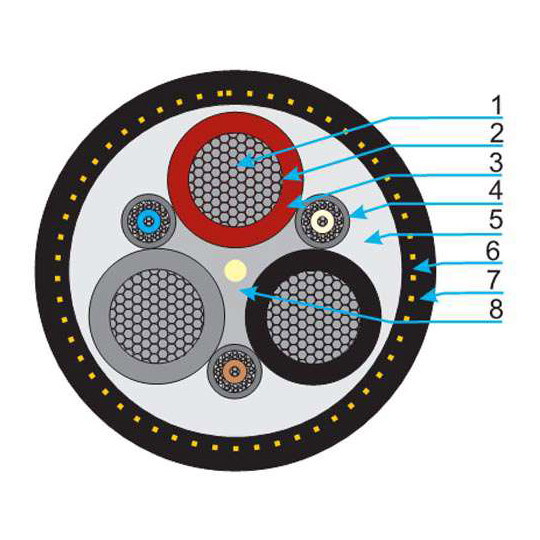

Advanced Multi-Layer Construction:

-

Conductor: Tinned copper, extra fine stranded (class 5) according to DIN VDE 0295

-

Separator: Polyester tape

-

Insulation: Rubber, compound type 3GI3 according to DIN VDE 0207 part 20

-

Special Pilot/Earth Core Element:

-

Copper and steel conductor capable of expansion and compression

-

EPR insulation covering

-

Earth core as spiral of tinned copper bunches covered with semi-conductive tape

-

-

Inner Sheath: Semi-conductive inner sheath

-

Reinforcement: Steel wire braid

-

Outer Sheath: Black chlorinated rubber compound 5GM5, abrasion and tear-resistant, oil-resistant and flame retardant

-

Core Arrangement: Cores laid up around semi-conductive cradle with centre Kevlar rope

Technical Data

Electrical & Mechanical Specifications:

-

Nominal Voltage U0/U: 0.6/1 kV

-

Permissible Surface Temperature:

-

Fixed installation: -40°C to +80°C

-

Moved installation: -25°C to +80°C

-

-

Maximum Conductor Temperature:

-

In service: +90°C

-

Short circuit: +200°C

-

-

Bending Radius:

-

Moved minimum: 3 × cable diameter

-

Fixed minimum: 2 × cable diameter

-

Guide pulleys and drums: 4.5 × cable diameter

-

-

Core Colors: Brown, black, grey

-

Sheath Colors: Black (other colors available)

Standards Compliance

Applied Standards:

-

VDE 0250 Part 812

-

DIN VDE 0472 Part 818 (Behaviour under clamping stress)

-

DIN VDE 0295 (Conductor standards)

-

DIN VDE 0207 Part 20 (Insulation standards)

Key Advantages

-

Proven Extreme Performance: Specifically designed for coal-cutting machines with very high mechanical loads

-

Advanced Safety Features: Comprehensive monitoring system detects insulation faults and external damage

-

Superior Flexibility: Maintains performance in free trailing, guide pulley, and reeling applications

-

Damage Detection: Specialized construction detects clamping damage as earth faults with maximum probability

-

Robust Material Selection: Combination of steel reinforcement and flexible materials for optimal performance

-

Industry Compliance: Meets German mining standards for safety and performance requirements

-

Versatile Application: Suitable for various mining equipment configurations with multiple pilot core options