Product Overview

NSSHCGEOEU Armored Coal Cutter Cable is specifically engineered for the most demanding mining applications where extreme mechanical stress is encountered. Designed for coal-cutting machines and other mobile mining equipment, this cable withstands extreme bending loads, high tensile stress, impact, and crushing loads while providing reliable power transmission in the harshest underground environments.

Key Features & Benefits

-

Exceptional Mechanical Durability: Withstands extreme bending loads, high tensile stress, impact, and crushing loads

-

Advanced Monitoring System: Integrated monitoring conductor enables continuous insulation fault detection

-

Superior Flexibility: Suitable for operation via guide pulleys (cable cars) and as reeling cable (LHD applications)

-

Robust Armor Protection: Tensile-stress-resistant braided armor of combined copper-steel wires

-

Enhanced Safety Features: Abrasion and tear-resistant outer sheath with oil resistance and flame retardant properties

-

Reliable Performance: Heat-resistant EPR insulation ensures stable operation in high-temperature environments

Applications

Extreme-duty mining and industrial applications:

-

Coal-Cutting Machines: Primary connection for coal cutting equipment in mining operations

-

Mobile Mining Machinery: Connection of mobile machines under extremely high mechanical loads

-

Guide Pulley Systems: Operation via cable cars and pulley systems

-

Reeling Applications: LHD (Load-Haul-Dump) reeling cable applications

-

High-Stress Environments: Mining situations requiring exceptional mechanical durability

-

Heavy-Duty Equipment: Applications with extreme bending and tensile stress requirements

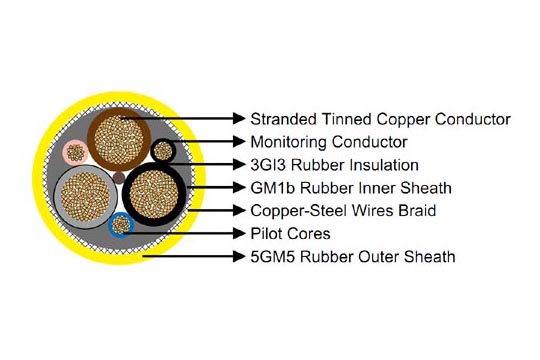

Construction

Advanced Multi-Layer Construction for Extreme Conditions:

-

Conductors: Flexible stranded tinned copper conductor

-

Insulation: Heat-resistant 3GI3 rubber based on EPR

-

Outer Conductor Layer: Easy strippable outer conductive layer

-

Pilot Cores: Copper and steel conductor capable of expansion and compression with 3GI3 EPR rubber insulation

-

Monitoring Conductor: Copper and steel conductor capable of expansion and compression covered with semi-conductive rubber compound

-

Inner Sheath: Rubber type GM1b

-

Armour/Earth Conductor: Concentric earth conductor as tensile-stress-resistant braided armour of combined copper-steel wires

-

Outer Sheath: Rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant

Specifications

Detailed Technical Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 3×16/16KON+2ST+UEL | 38.5 | 41.5 | 2430 |

| 3×25/16KON+2ST+UEL | 41.0 | 44.5 | 3050 |

| 3×35/16KON+2ST+UEL | 44.5 | 48.0 | 3620 |

| 3×50/25KON+2ST+UEL | 50.0 | 54.0 | 4810 |

| 3×70/35KON+2ST+UEL | 54.5 | 58.5 | 5890 |

| 3×95/50KON+2ST+UEL | 62.5 | 66.5 | 7800 |

| 3×35/16KON+3ST+3UEL | 44.5 | 48.0 | 3860 |

| 3×50/25KON+3ST+3UEL | 50.0 | 54.0 | 5050 |

| 3×70/35KON+3ST+3UEL | 54.5 | 58.5 | 6000 |

| 3×95/50KON+3ST+3UEL | 62.5 | 66.5 | 8050 |

| 3×120/70KON+3ST+3UEL | 67.5 | 72.0 | 9380 |

| 3×150/70KON+3ST+3UEL | 74.5 | 79.0 | 11120 |

Key Advantages

-

Proven Extreme Durability: Specifically designed for coal-cutting machines and high-stress mining applications

-

Comprehensive Protection: Multiple protective layers including braided copper-steel armor

-

Superior Mechanical Performance: Withstands extreme bending, tensile stress, impact, and crushing loads

-

Enhanced Safety: Integrated monitoring system for real-time fault detection

-

Flexible Application: Suitable for guide pulleys, reeling systems, and various mining equipment

-

Reliable Operation: Maintains performance in the most demanding mining environments

-

Industry Standard Compliance: Meets VDE 0250 standards for mining cable applications