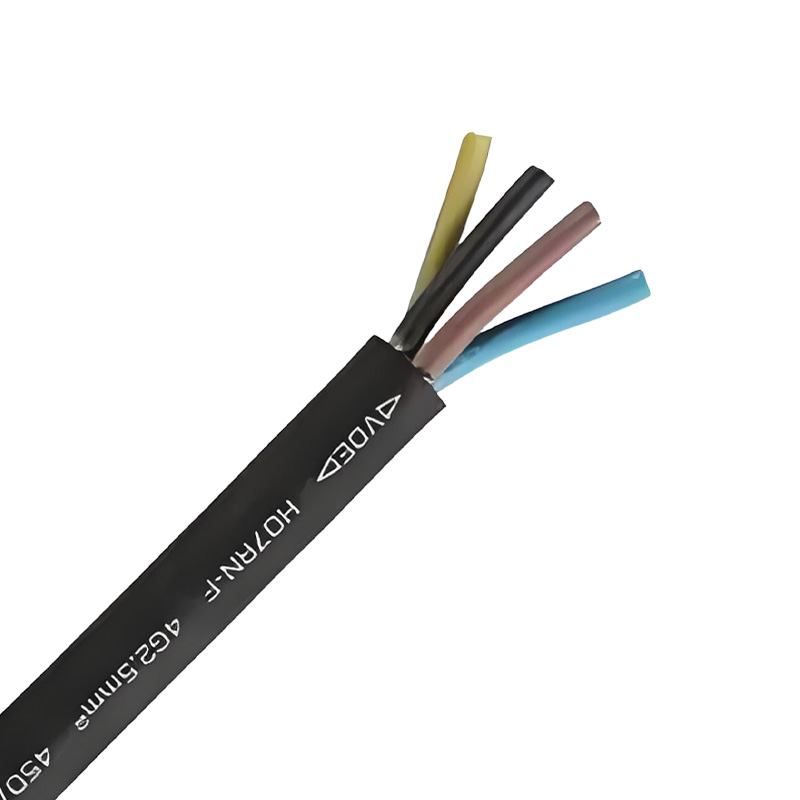

Product Overview

H07RN-F Rubber Insulated Flexible Cable 450/750V is engineered for demanding industrial applications requiring exceptional flexibility and environmental resistance. Featuring robust rubber insulation and oil-resistant flame retardant sheath, this cable delivers reliable performance in both fixed installations and mobile applications across various challenging environments.

Key Features & Benefits

-

Superior Flexibility: Class 5 stranded copper conductors ensure excellent flexibility for easy handling

-

Environmental Resistance: Oil-resistant and flame retardant CR/PCP rubber outer sheath

-

Wide Temperature Range: Suitable for static applications from -40°C to +60°C

-

Multiple Application Modes: Suitable for fixed installations and mobile applications

-

Enhanced Safety: Approved for use in explosion hazard areas and damp environments

-

Versatile Configuration: Available in single-core and multi-core configurations up to 24 cores

Applications

Comprehensive industrial and commercial applications:

-

Heating Units & Industrial Tools: Connection of vulcanization plates and hand-operated equipment

-

Mobile Equipment & Machinery: Transportable motors and portable industrial equipment

-

Building Sites & Construction: Provisional constructions and temporary power distribution

-

Industrial & Agricultural Applications: Conveyor systems and agricultural machinery

-

Hazardous Areas: Explosion hazard areas and outdoor installations

-

Rotor Supply: Authorized for 1000V as rotor supply cable for engines when protected

Construction

Advanced Flexible Construction:

-

Conductors: Stranded copper conductor, class 5 (DIN VDE 0295/HD 383 S2)

-

Insulation: Rubber type EI4 (DIN VDE 0282 Part 1/HD 22.1)

-

Inner Sheath: NR/SBR rubber type EM1 (for ≥10mm² or more than 5 cores)

-

Outer Sheath: CR/PCP rubber type EM2 - oil-resistant and flame retardant

Technical Data

Electrical Ratings:

-

Rated Voltage U0/U: 450V/750V

-

Special Authorization: 1000V when laid protected in pipes or as rotor supply cable

Temperature Ratings:

-

Static Applications: -40°C to +60°C

-

Flexing Applications: -25°C to +60°C

Bending Radius Requirements:

-

Fixed Installation:

-

Up to 12mm diameter: 3 × cable diameter

-

Above 12mm diameter: 4 × cable diameter

-

-

Mobile Application:

-

Up to 12mm diameter: 4 × cable diameter

-

12-20mm diameter: 5 × cable diameter

-

Above 20mm diameter: 6 × cable diameter

-

Specifications

Detailed Technical Specifications:

| Number of Cores × Nominal Cross Section | Insulation Thickness | Thickness of Inner Sheath | Thickness of Outer Sheath | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|---|---|---|

| No.×mm² | mm | mm | mm | mm | mm | kg/km |

| 1×1.5 | 0.8 | – | 1.4 | 5.7 | 6.7 | 60 |

| 2×1.5 | 0.8 | – | 1.5 | 8.5 | 10.5 | 120 |

| 3G1.5 | 0.8 | – | 1.6 | 9.2 | 11.2 | 170 |

| 4G1.5 | 0.8 | – | 1.7 | 10.2 | 12.5 | 210 |

| 5G1.5 | 0.8 | – | 1.8 | 11.2 | 13.5 | 260 |

| 7G1.5 | 0.8 | 1.0 | 1.6 | 14.0 | 17.0 | 360 |

| 12G1.5 | 0.8 | 1.2 | 1.7 | 17.6 | 20.5 | 515 |

| 19G1.5 | 0.8 | 1.4 | 2.1 | 20.7 | 26.3 | 795 |

| 24G1.5 | 0.8 | 1.4 | 2.1 | 24.3 | 28.5 | 920 |

| 1×2.5 | 0.9 | – | 1.4 | 6.3 | 7.5 | 75 |

| 2×2.5 | 0.9 | – | 1.7 | 10.2 | 12.5 | 170 |

| 3G2.5 | 0.9 | – | 1.8 | 10.9 | 13.0 | 230 |

| 4G2.5 | 0.9 | – | 1.9 | 12.1 | 14.5 | 290 |

| 5G2.5 | 0.9 | – | 2.0 | 13.3 | 16.0 | 360 |

| 7G2.5 | 0.9 | 1.1 | 1.7 | 17.0 | 20.0 | 510 |

| 12G2.5 | 0.9 | 1.2 | 1.9 | 20.6 | 23.5 | 740 |

| 19G2.5 | 0.9 | 1.5 | 2.2 | 24.4 | 30.9 | 1190 |

| 24G2.5 | 0.9 | 1.6 | 2.3 | 28.8 | 33.0 | 1525 |

| 1×4 | 1.0 | – | 1.5 | 7.2 | 8.5 | 100 |

| 2×4 | 1.0 | – | 1.8 | 11.8 | 14.5 | 195 |

| 3G4 | 1.0 | – | 1.9 | 12.7 | 15.0 | 305 |

| 4G4 | 1.0 | – | 2.0 | 14.0 | 17.0 | 400 |

| 5G4 | 1.0 | – | 2.2 | 15.6 | 19.0 | 505 |

| 1×6 | 1.0 | – | 1.6 | 7.9 | 9.5 | 130 |

| 2×6 | 1.0 | – | 2.0 | 13.1 | 16.0 | 285 |

| 3G6 | 1.0 | – | 2.1 | 14.1 | 17.0 | 380 |

| 4G6 | 1.0 | – | 2.3 | 15.7 | 19.0 | 550 |

| 5G6 | 1.0 | – | 2.5 | 17.5 | 21.0 | 660 |

| 1×10 | 1.2 | – | 1.8 | 9.5 | 11.5 | 195 |

| 2×10 | 1.2 | 1.2 | 1.9 | 17.7 | 21.5 | 565 |

| 3G10 | 1.2 | 1.3 | 2.0 | 19.1 | 22.5 | 715 |

| 4G10 | 1.2 | 1.4 | 2.0 | 20.9 | 24.5 | 875 |

| 5G10 | 1.2 | 1.4 | 2.2 | 22.9 | 27.0 | 1095 |

| 1×16 | 1.2 | – | 1.9 | 10.8 | 13.0 | 280 |

| 2×16 | 1.2 | 1.3 | 2.0 | 20.2 | 23.5 | 795 |

| 3G16 | 1.2 | 1.4 | 2.1 | 21.8 | 25.5 | 1040 |

| 4G16 | 1.2 | 1.4 | 2.2 | 23.8 | 28.0 | 1280 |

| 5G16 | 1.2 | 1.5 | 2.4 | 26.4 | 31.0 | 1610 |

| 1×25 | 1.4 | – | 2.0 | 12.7 | 15.0 | 405 |

| 4G25 | 1.4 | 1.6 | 2.2 | 28.9 | 33.0 | 1890 |

| 5G25 | 1.4 | 1.7 | 2.7 | 32.0 | 36.0 | 2335 |

| 1×35 | 1.4 | – | 2.2 | 14.3 | 17.0 | 545 |

| 4G35 | 1.4 | 1.7 | 2.7 | 32.5 | 36.5 | 2505 |

| 5G35 | 1.4 | 1.8 | 2.8 | 35.0 | 39.5 | 2718 |

| 1×50 | 1.6 | – | 2.4 | 16.5 | 19.5 | 730 |

| 4G50 | 1.6 | 1.9 | 2.9 | 37.7 | 42.0 | 3350 |

| 5G50 | 1.6 | 2.1 | 3.1 | 41.0 | 46.0 | 3804 |

| 1×70 | 1.6 | – | 2.6 | 18.6 | 22.0 | 955 |

| 4G70 | 1.6 | 2.0 | 3.2 | 42.7 | 47.0 | 4785 |

| 1×95 | 1.8 | – | 2.8 | 20.8 | 24.0 | 1135 |

| 4G95 | 1.8 | 2.3 | 3.6 | 48.4 | 54.0 | 6090 |

| 1×120 | 1.8 | – | 3.0 | 22.8 | 26.5 | 1560 |

| 4G120 | 1.8 | 2.4 | 3.6 | 53.0 | 59.0 | 7550 |

| 5G120 | 1.8 | 2.8 | 4.0 | 59.0 | 65.0 | 8290 |

| 1×150 | 2.0 | – | 3.2 | 25.2 | 29.0 | 1925 |

| 4G150 | 2.0 | 2.6 | 3.9 | 58.0 | 64.0 | 8495 |

| 1×185 | 2.2 | – | 3.4 | 27.6 | 31.5 | 2230 |

| 4G185 | 2.2 | 2.8 | 4.2 | 64.0 | 71.0 | 9850 |

| 1×240 | 2.4 | – | 3.5 | 30.6 | 35.0 | 2945 |

| 1×300 | 2.6 | – | 3.6 | 33.5 | 38.0 | 3495 |

| 1×630 | 3.0 | – | 4.1 | 45.5 | 51.0 | 7020 |

Key Advantages

-

Proven Reliability: German standards compliance ensures consistent quality

-

Wide Application Range: Suitable for diverse industrial environments

-

Optimized Flexibility: Maintains performance in both static and mobile applications

-

Safety Compliance: Approved for hazardous areas and demanding conditions

-

Comprehensive Size Range: Available from 1.5mm² to 630mm² in various configurations