Product Overview

Type SHD-CGC Shield Ground-Check Power Cable - 5KV is engineered for maximum safety in heavy-duty mining applications where ground-check monitoring and metallic shielding are mandatory. This cable provides superior protection against induced voltages and hazardous conditions in underground mining operations, featuring robust construction with specialized grounding systems.

Key Features & Benefits

-

Enhanced Safety System: Integrated ground-check conductor provides fail-safe monitoring for maximum safety

-

Superior Shielding Protection: Flexible coated copper/textile braid shield prevents shock hazards

-

Exceptional Durability: Reinforced two-layer CPE jacket resists cutting, impact, abrasion, and flame

-

Extended Flexibility: Rope-lay-stranded conductors per ASTM B172 with specialized stranding for ground-check conductor

-

Environmental Resistance: Excellent heat, moisture, steam, oil, chemical and radiation resistance

-

Thermal Stability: Maintains physical properties over a broad temperature range

Applications

Critical mining applications requiring maximum safety:

-

Longwall Shearer Equipment: Trailing cables for underground mining machines

-

Continuous Miners & Loaders: Mobile equipment requiring grounding conductors

-

Drills & Conveyors: Heavy-duty mining machinery power supply

-

Pumps & Mobile Equipment: Applications where induced voltages could be hazardous

-

Underground Mining: Low- and medium-voltage AC circuits requiring shielding

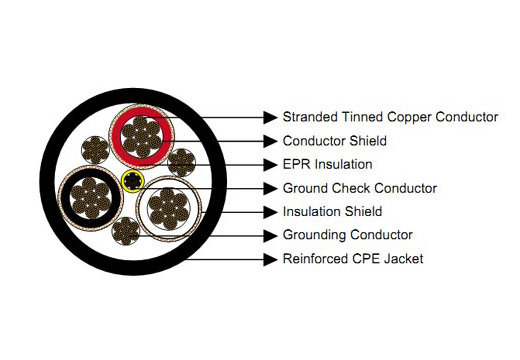

Construction

Advanced Safety-Focused Construction:

-

Conductor:

-

1 AWG thru 500 kcmil coated annealed copper

-

Bunched wires, rope-lay-stranded per ASTM B172

-

-

Insulation:

-

Ethylene Propylene Rubber (EPR) insulation

-

-

Insulation Shield:

-

Flexible coated copper/textile braid shield

-

Applied over non-conducting overlapped tape

-

-

Ground-Check Conductor:

-

Coated copper, specially stranded for extensibility

-

Insulated with high-strength polypropylene

-

Placed in the center interstice

-

-

Grounding Conductors:

-

Three coated copper conductors

-

Rope-lay-stranded per ASTM B172

-

In contact with the flexible braid shield

-

-

Jacket:

-

Reinforced, two-layer, extra-heavy-duty

-

Lead-cured Chlorinated Polyethylene (CPE)

-

Specifications

Detailed Technical Specifications:

| Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | |

|---|---|---|---|---|---|---|---|---|---|

| No. of cores×AWG/kcmil | – | AWG/kcmil | AWG/kcmil | inch/mm | inch/mm | inch/mm | lbs/kft | kg/km | A |

| 3×2/0 | 323 | 5 | 16 | 0.11/2.8 | 0.220/5.6 | 2.20/55.9 | 3716 | 5529 | 243 |

| 3×3/0 | 418 | 4 | 16 | 0.11/2.8 | 0.235/6.0 | 2.36/59.9 | 4130 | 6145 | 279 |

| 3×4/0 | 532 | 3 | 16 | 0.11/2.8 | 0.235/6.0 | 2.50/63.5 | 5190 | 7722 | 321 |

| 3×350 | 888 | 1 | 16 | 0.12/3.0 | 0.265/6.7 | 2.95/74.9 | 7571 | 11264 | 435 |

*Ampacity based on 90°C conductor temperature and 40°C ambient air temperature per ICEA S-75-381*

Mechanical and Thermal Properties

Performance Specifications:

-

Minimum Bending Radius: 6 × Outer Diameter

-

Maximum Conductor Operating Temperature: +90°C

-

Ampacity Rating: As specified in table above

Standards Compliance

Applied Standards:

-

ICEA S-75-381/NEMA WC 58

-

ASTM B 172

-

ASTM B 33

Options & Customization

Available Options:

-

Alternative jacket materials: CSP/PCP/NBR/PVC available upon request

-

Two-layer jacket with reinforcing fibre between layers available as option

Key Advantages

-

Maximum Safety Compliance: Designed for applications where maximum safety is mandatory

-

Hazard Protection: Protects against induced voltages in unbalanced grounding systems

-

Flexible Shield Design: Provides shock hazard protection while maintaining flexibility

-

Proven Reliability: Extra-heavy-duty construction withstands most demanding mining conditions

-

Industry Standard Compliance: Meets all relevant mining cable standards and specifications