Product Overview

This Copper/XLPE/PVC/STA/PVC Power Cable is engineered for fixed installations in power distribution networks up to 35kV. Compliant with GB/T 12706.1-2008 and international fire safety standards (BS 6387, IEC 60332), it features triple-layer protection: XLPE insulation, steel tape armour (STA), and dual PVC sheathing for reliable operation in demanding environments.

Key Technical Specifications

| Parameter | Specification |

|---|---|

| Standard | GB/T 12706.1-2008 (1kV-35kV) |

| Conductor | Class 2 Copper (IEC 60228) |

| Insulation | XLPE (Cross-Linked Polyethylene) |

| Screening | Dual Semi-Conductive Layers (Conductor + Insulation) |

| Armour | Galvanized Steel Tape (STA) |

| Sheath | Inner PVC Bedding + Outer PVC/PE/LSOH Jacket |

| Voltage Rating | 0.6/1kV, 1.8/3kV, 6/10kV, 8.7/15kV, 26/35kV |

| Fire Performance | IEC 60332-3-22/23/24 + BS 6387 (Circuit Integrity) |

| Operating Temp | -20°C to +90°C (Conductor) |

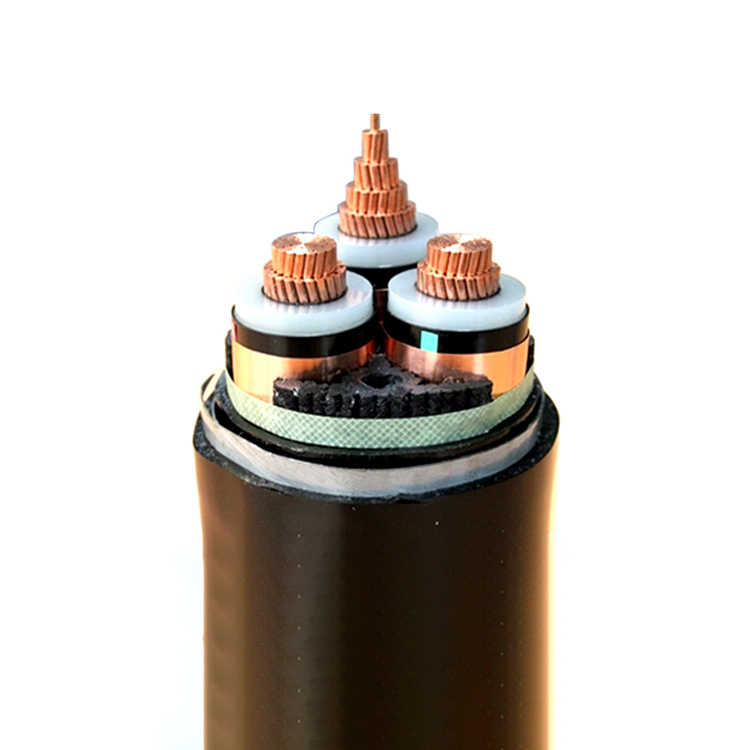

Construction Details

-

Conductor: Compacted stranded copper (Class 2 per IEC 60228)

-

Conductor Screen: Extruded semi-conductive layer

-

Insulation: Thermoset XLPE (PE-X)

-

Insulation Screen: Extruded semi-conductive layer + copper tape

-

Bedding: PVC inner sheath

-

Armour: Helical steel tape (anti-corrosion treated)

-

Jacket: Outer PVC (Black/Red/Custom) or LSOH

Product Advantages

-

⚡ Enhanced Safety: Dual semi-conductive screens eliminate partial discharges

-

🔥 Superior Fire Resistance: Meets BS 6387 (C-W-Z) circuit integrity requirements

-

🛡️ Mechanical Protection: STA armour resists crushing and rodent damage

-

🌧️ Environmental Durability: Water-blocking fillers + corrosion-resistant layers

-

🔌 Stable Performance: XLPE maintains low dielectric loss over lifetime

Application Scenarios

-

Power Substations: Transformer connections and switchgear terminations

-

Industrial Plants: Fixed installations in cable trenches/tunnels

-

Infrastructure: Power networks in airports, hospitals, and metro systems

-

High-Risk Areas: Locations requiring circuit integrity during fire (BS 8491)

Not suitable for dynamic/tension applications

Fire Performance Compliance

| Test | Standard | Requirement |

|---|---|---|

| Flame Propagation | IEC 60332-3-22/23/24 | Category A/B/C |

| Circuit Integrity | BS 6387 | 950°C/3h (Category C-W-Z) |

| Halogen Emission | IEC 60754-1/2 | Gas acidity/pH compliance |

Certifications & Packaging

-

Standards: GB/T 12706.1, IEC 60502, BS 6622

-

Certifications: CE, RoHS, ISO 9001

-

Packaging: Export wooden drums (cable length/drum per request)