6/10kV N2XSEY XLPE Insulated Medium Voltage Power Cables

Product Overview

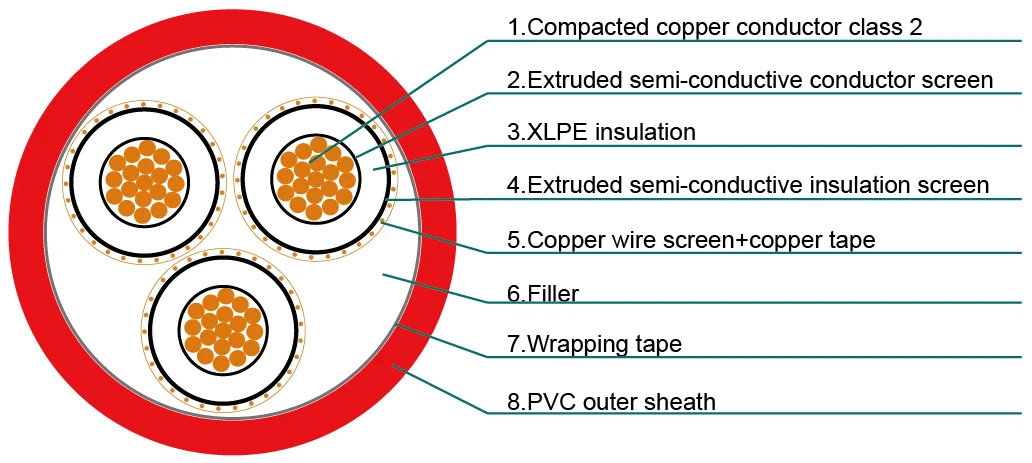

The N2XSEY designates a German-standard medium voltage cable with triple-layer screened construction:

-

N: Normenleitung (standard cable)

-

2X: XLPE insulation

-

S: Copper wire screen

-

E: Copper tape screen

-

Y: PVC sheath

This configuration provides exceptional electrical stress control, making it ideal for 6-10kV distribution networks where partial discharge suppression and EMI protection are critical. The robust copper screening ensures fault current capacity up to 25kA for 1s.

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | U<sub>0</sub>/U = 6/10kV (U<sub>m</sub>: 12kV) |

| Standards | DIN VDE 0276-620, HD 620, EN 60228 |

| Flame Performance | IEC/EN 60332-1-2 |

| Impulse Withstand | 75kV |

| Temp. Range | Fixed: -20°C to +70°C Flexed: -5°C to +70°C |

| Short Circuit | 250°C (5s max) |

| Bending Radius | 15 × OD |

Cable Construction

1. Conductor

-

Material: Compacted copper (Class 2 per EN 60228)

-

Structure: Stranded, compact round

2. Semi-Conductive Layers

-

Conductor screen: Equipotential stress control

-

Insulation screen: PD suppression (>1pC)

3. Insulation

-

Material: XLPE

-

Thickness: 3.4mm (constant across 25-500mm²)

4. Metallic Screen

-

Copper wire braid + helically applied copper tape

5. Outer Sheath

-

Standard: PVC (ST1)

-

Optional: HDPE (UV-resistant)

-

Color: RAL 3000 Red

Technical Data Table

| Cross-Section (mm²) | Conductor Ø (mm) | Approx. OD (mm) | Weight (kg/km) | Current Rating* (A) |

|---|---|---|---|---|

| 25 | 6.0 | 48.0 | 4,175 | 180 |

| 35 | 7.2 | 50.8 | 4,733 | 220 |

| 50 | 8.4 | 53.8 | 5,491 | 265 |

| 70 | 10.0 | 57.6 | 6,446 | 320 |

| 95 | 11.7 | 61.5 | 7,530 | 380 |

| 120 | 13.1 | 64.9 | 8,628 | 435 |

| 150 | 14.6 | 68.3 | 9,794 | 500 |

| 185 | 16.3 | 72.6 | 11,326 | 570 |

| 240 | 18.5 | 79.2 | 14,268 | 670 |

| 300 | 20.7 | 84.8 | 16,641 | 750 |

| 400 | 23.8 | 92.3 | 20,362 | 870 |

| 500 | 26.6 | 99.3 | 24,203 | 980 |

| *Based on IEC 60502-2 (40°C ambient, 0.7m burial) |

Key Features

-

Partial Discharge Control: <5pC at 1.5U<sub>0</sub>

-

EMI Shielding: 98% screening efficiency

-

Moisture Resistance: Longitudinal water-blocking design

-

Thermal Cycling: Withstands ΔT=100°C without degradation

-

Corrosion Protection: PVC sheath prevents electrochemical corrosion

Application Environments

| Installation Type | Requirements |

|---|---|

| Direct Burial | Minimum depth: 0.7m (trench with sand bed) |

| Cable Ducts | Max. pulling tension: 50N/mm² |

| Power Stations | Clearance from heat sources: >300mm |

| Industrial Plants | Chemical resistance: pH 4-10 |

| Outdoor Installations | UV-stabilized sheath option available |

Engineering Selection Guide

-

Fault Current Calculation:

-

I<sub>sc</sub> = k × S / √t (k=115 for copper)

-

Example: 240mm² cable = 115×240 = 27.6kA for 1s

-

-

Voltage Drop Verification:

ΔU(%) = √3 × I<sub>b</sub> × L × (Rcosφ + Xsinφ) / 10 × U<sub>n</sub>-

R = 0.075Ω/km (for 150mm²)

-

X = 0.101Ω/km

-

-

Bending Radius Compliance:

-

During installation: 20×OD

-

Post-installation: 15×OD

-

Certifications:

• CE Marking • ISO 9001:2015 • VDE Test Certificate

Packaging:

-

Export-grade steel-wood drums

-

Anti-corrosion vapor barrier

-

Custom lengths available

Ordering Information:

*Available in 25-500mm² cross-sections. Request project-specific short-circuit calculations and datasheets.*