1. Product Overview:

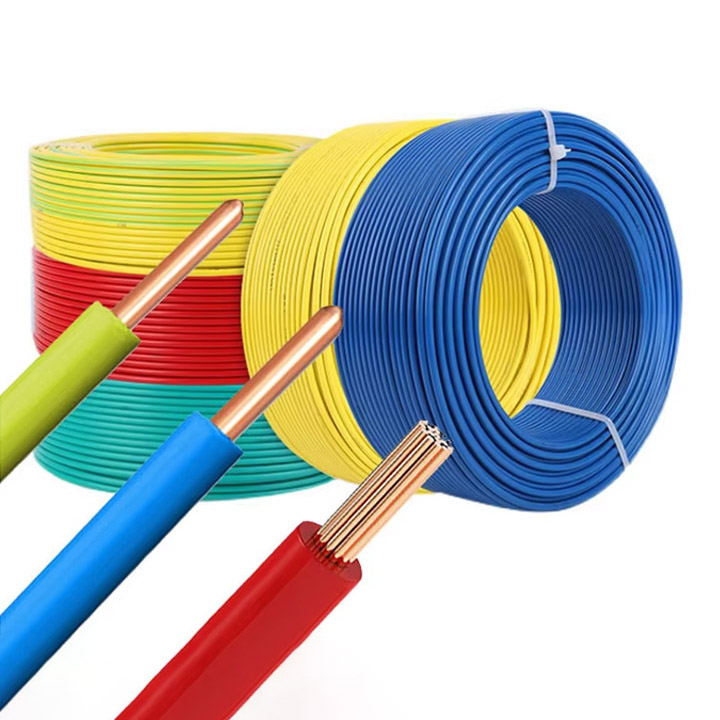

The H07V-U, H07V-R, and H07V-K are single-core, PVC-insulated copper conductor wires rated at 450/750V. Designed for internal wiring, equipment connections, and fixed installations within electrical apparatus, these wires comply with international standards including IEC 60227, HD 516, VDE 0295, and relevant parts of IEC 60228. They offer reliable performance in diverse industrial and commercial electrical applications.

2. Key Standards & Approvals:

-

Voltage Rating: 450/750V

-

Conformance: IEC 60227, HD 516, VDE 0295, IEC 60228

-

Flame Retardant: IEC 60332-1

-

Certification: CE Marked (Presumed compliance with LVD 2014/35/EU)

3. Construction:

-

Conductor: Bare Copper

-

H07V-U: Solid Circular Conductor (Class 1 per IEC 60228/VDE 0295)

-

H07V-R: Stranded Circular Conductor (Class 2 per IEC 60228/VDE 0295)

-

H07V-K: Finely Stranded Flexible Circular Conductor (Class 5 per IEC 60228/VDE 0295)

-

-

Insulation: Polyvinyl Chloride (PVC)

4. Material Properties & Advantages:

-

Flexibility: H07V-K (Class 5) offers superior flexibility for complex routing; H07V-R (Class 2) provides moderate flexibility; H07V-U (Class 1) is rigid.

-

Durability: PVC insulation provides good resistance to abrasion, moisture, oils, and common chemicals.

-

Flame Retardant: Meets IEC 60332-1 for flame propagation resistance (single wire flame test).

-

Electrical Integrity: High insulation resistance (≥ 10 MΩ·km at 20°C).

-

Temperature Range:

-

Static Installation (Fixed): -30°C to +80°C

-

Flexing Installation (During Bending): -5°C to +70°C

-

5. Application Scenarios:

-

Internal Wiring: Electric motors, transformers, generators.

-

Equipment Wiring: Switchgear, control panels, distribution boards, appliances (measuring, regulating, controlling), lighting fixtures.

-

Fixed Installations: Dry rooms, production facilities, switchboards, industrial plants.

-

Installation Methods: Inside conduit, pipes, cable ducts, under plaster, surface mounting (clipped), within electrical enclosures and apparatus. Primarily for indoor use or protected industrial environments.

-

Specific Use Cases:

-

H07V-K: Highly flexible wiring for motors, appliances with moving parts, complex panel wiring, frequent connection/disconnection points.

-

H07V-U: General internal wiring of apparatus, lighting circuits, surface/plaster mounting, cost-effective solutions where flexibility is not critical.

-

H07V-R: Switchboards, distributor boards, industrial control panels, conduit/duct installations requiring more flexibility than solid core but less than fine strand.

-

6. Key Technical Parameters:

| Parameter | Value / Rating | Standard/Notes |

|---|---|---|

| Rated Voltage (Uo/U) | 450V / 750V | IEC 60227 |

| Routine Test Voltage | 2500V AC, 5 min | IEC 60227 |

| Insulation Resistance | ≥ 10 MΩ·km (20°C) | IEC 60227 |

| Min. Bending Radius | 12.5 x Overall Diameter (Ø) | During Installation/Use |

| Flame Retardancy | Compliant with IEC 60332-1 | Single wire vertical flame test |

| Max. Conductor Temp. (Op.) | +70°C | |

| Max. Conductor Temp. (Short Circuit) | +160°C (1s) / +140°C (5s) | Typical PVC, refer IEC 60227 for calc. |

7. Engineering Selection Data (Complete):

H07V-K (Class 5 Flexible - Finely Stranded):

| Conductor Size (mm²) | Stranding (No./mm) | Nom. OD (mm) | Nom. Copper Wt (kg/km) | Nom. Cable Wt (kg/km) |

|---|---|---|---|---|

| 1 x 1.5 | 30/0.25 (30/30) | 3.1 | 14.4 | 20 |

| 1 x 2.5 | 50/0.25 (50/30) | 3.6 | 24.0 | 31 |

| 1 x 4 | 56/0.30 (56/28) | 4.3 | 38.0 | 48 |

| 1 x 6 | 84/0.30 (84/28) | 4.9 | 58.0 | 69 |

| 1 x 10 | 80/0.40 (80/26) | 6.4 | 96.0 | 121 |

| 1 x 16 | 128/0.40 (128/26) | 8.1 | 154.0 | 211 |

| 1 x 25 | 200/0.40 (200/26) | 9.8 | 240.0 | 303 |

| 1 x 35 | 280/0.40 (280/26) | 11.1 | 336.0 | 417 |

| 1 x 50 | 400/0.40 (400/26) | 13.1 | 480.0 | 539 |

| 1 x 70 | 356/0.50 (356/24) | 15.5 | 672.0 | 730 |

| 1 x 95 | 485/0.50 (485/24) | 17.2 | 912.0 | 900 |

| 1 x 120 | 614/0.50 (614/24) | 19.7 | 1152.0 | 1135 |

| 1 x 150 | 765/0.50 (765/24) | 21.3 | 1440.0 | 1410 |

| 1 x 185 | 944/0.50 (944/24) | 23.4 | 1776.0 | 1845 |

| 1 x 240 | 1225/0.50 (1225/24) | 27.1 | 2304.0 | 2270 |

H07V-U (Class 1 Solid - Rigid):

| Conductor Size (mm²) | Stranding | Nom. OD (mm) | Nom. Copper Wt (kg/km) | Nom. Cable Wt (kg/km) |

|---|---|---|---|---|

| 1 x 0.5 | Solid | 2.1 | 4.8 | 9 |

| 1 x 0.75 | Solid | 2.2 | 7.2 | 11 |

| 1 x 1.0 | Solid | 2.4 | 9.6 | 14 |

| 1 x 1.5 | Solid | 2.9 | 14.4 | 21 |

| 1 x 2.5 | Solid | 3.5 | 24.0 | 33 |

| 1 x 4 | Solid | 3.9 | 38.0 | 49 |

| 1 x 6 | Solid | 4.5 | 58.0 | 69 |

| 1 x 10 | Solid | 5.7 | 96.0 | 115 |

H07V-R (Class 2 Stranded - Standard Stranded):

| Conductor Size (mm²) | Stranding (No./mm) | Nom. OD (mm) | Nom. Copper Wt (kg/km) | Nom. Cable Wt (kg/km) |

|---|---|---|---|---|

| 1 x 1.5 | 7/0.52 (7/24) | 3.0 | 14.4 | 23 |

| 1 x 2.5 | 7/0.67 (7/22) | 3.6 | 24.0 | 35 |

| 1 x 4 | 7/0.85 (7/20) | 4.2 | 38.4* (39) | 51 |

| 1 x 6 | 7/1.04 (7/18) | 4.7 | 57.6* (58) | 71 |

| 1 x 10 | 7/1.35 (7/16) | 6.1 | 96.0 | 120 |

| 1 x 16 | 7/1.70 (7/14) | 7.2 | 153.6* (154) | 170 |

| 1 x 25 | 7/2.14 (7/12) | 8.4 | 240.0 | 260 |

| 1 x 35 | 7/2.52 (7/10) | 9.5 | 336.0 | 350 |

| 1 x 50 | 19/1.78 (19/13) | 11.3 | 480.0 | 480 |

| 1 x 70 | 19/2.14 (19/11) | 12.6 | 672.0 | 680 |

| 1 x 95 | 19/2.52 (19/10) | 14.7 | 912.0 | 930 |

| 1 x 120 | 37/2.00 (37/12) | 16.2 | 1152.0 | 1160 |

| 1 x 150 | 37/2.24 (37/11) | 18.1 | 1440.0 | 1430 |

| 1 x 185 | 37/2.50 (37/10) | 20.2 | 1776.0 | 1780 |

| 1 x 240 | 61/2.24 (61/11) | 22.9 | 2304.0 | 2360 |

| 1 x 300 | 61/2.50 (61/10) | 24.5 | 2880.0 | 2940 |

| 1 x 400 | 61/2.85 (61/11)* | 27.5 | 3840.0 | 3740 |

Note:

-

OD= Nominal Overall Diameter.Copper Wt= Nominal Conductor Weight.Cable Wt= Nominal Total Cable Weight. -

Stranding notation: e.g.,

7/0.52= 7 wires of 0.52mm diameter. Values in parentheses (e.g.,7/24) are common industry shorthand. -

*Minor discrepancies in calculated vs. listed copper weight for some H07V-R sizes exist in source data; values listed per source document.

-

Weights and diameters are nominal; consult manufacturer's full specification sheet for exact tolerances and complete size range.

8. Installation Notes:

-

Environment: Primarily for fixed installations indoors and in protected, dry environments.

-

Bending: Strictly adhere to minimum bending radius (12.5 x Ø) during installation and operation to prevent conductor or insulation damage.

-

Codes & Standards: Installation must comply with local electrical codes and regulations (e.g., IEC 60364, NEC, CEC, national wiring rules).

-

Conductor Selection: Choose appropriate type (U/R/K) based on required flexibility, vibration resistance, and installation method.

-

Protection: Not rated for direct burial, continuous outdoor exposure, or use in wet locations unless adequately protected within conduit, trunking, or suitable enclosures rated for the environment.

-

Termination: Ensure proper termination techniques suitable for the conductor class (solid, stranded, fine-stranded) are used.