Product Overview

ZR-KFGP flame-retardant silicone rubber control cables deliver unmatched performance in extreme industrial environments. Designed for 450/750V control circuits, these cables combine fluoroplastic insulation with silicone rubber sheathing and copper braid shielding to withstand continuous temperatures from -60°C to +180°C (200°C peak). Ideal for steel mills, power plants, petrochemical facilities, and aviation systems where high-temperature stability, chemical resistance, and flame retardancy are critical.

Key Features & Benefits

-

Extreme Temperature Range: Continuous operation at -60°C to +180°C (200°C short-term)

-

Flame Retardant (ZR): Self-extinguishing per GB12666-90 (IEC 60332-1 equivalent)

-

Chemical Immunity: Resists oils, acids, solvents, and humidity

-

EMI Protection: Copper braid shielding (≥85% coverage) for signal integrity

-

Flexible in Cold: Maintains pliability at -60°C (no cracking)

-

Short-Circuit Resilience: Withstands 250°C for ≤5 seconds

Critical Applications

-

Steel smelting furnaces & rolling mills

-

Power plant boiler controls

-

Petrochemical refinery pump systems

-

Aviation engine test facilities

-

Coking plant conveyor networks

-

Port machinery in coastal environments

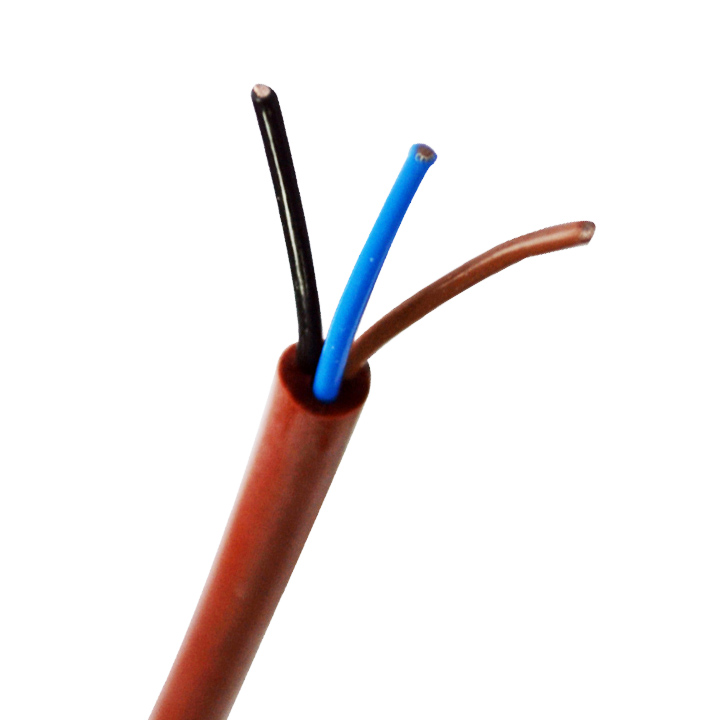

Cable Construction

-

Conductor:

-

Stranded tinned copper wire (IEC 60228 Class 5/6)

-

-

Insulation:

-

Fluoroplastic (FEP Teflon®) - Superior dielectric strength at high temps

-

-

Shielding:

-

Braided tinned copper wire (KFGP models)

-

-

Outer Sheath:

-

Reinforced silicone rubber - UV/ozone/abrasion resistant

-

Product Matrix & Specifications

| Model | Construction | Key Features | Temp Range | Bending Radius |

|---|---|---|---|---|

| ZR-KFG | Fluoroplastic + Silicone | Chemical/heat resistance | -60°C to +200°C | ≥10D |

| ZR-KFGP | + Copper braid shielding | EMI protection + flexibility | -60°C to +200°C | ≥10D |

| ZR-KFGR | Flexible core | Robotic arms, moving machinery | -60°C to +180°C | ≥16D |

| ZR-KFG22 | + Steel tape armor | Direct burial, high-crush zones | -60°C to +180°C | ≥12D |

| ZR-KGG | Silicone insulation + sheath | General high-temp mobility | -50°C to +180°C | ≥6D |

| ZR-KGGP | + Shielding | Signal-critical systems | -50°C to +180°C | ≥6D |

Technical Parameters

| Parameter | Specification | Standard/Test Method |

|---|---|---|

| Rated Voltage | 450/750V AC | IEC 60502-1 |

| Continuous Temp | -60°C to +180°C (KFGP) | IEC 60811 |

| Peak Temp | +200°C (≤1 hour daily) | IEC 60216 |

| Short-Circuit Temp | 250°C (≤5 sec) | IEC 60364-4-43 |

| Flame Retardancy | ≤250mm damage (GB12666-90 Cat. A) | GB12666-90 / IEC 60332-1 |

| Insulation Resistance | ≥100 MΩ·km (20°C) | IEC 60228 |

| Bending Radius | 10-16× cable diameter (model-dependent) | IEC 60273 |

Material Advantages

| Component | Benefits |

|---|---|

| Fluoroplastic (FEP) | Withstands acids/alkalis at 200°C+; low smoke emission |

| Silicone Rubber | Retains elasticity at -60°C; self-extinguishing |

| Tinned Copper | Corrosion resistance in salty/humid environments |

| Copper Braid | 90% EMI attenuation (30MHz-1GHz) |

Engineering Selection Guide

-

Temperature Exposure:

-

180°C continuous: Fluoroplastic-core (KFG series)

-

<180°C: Silicone-core (KGG series)

-

-

Environmental Hazards:

-

Chemical splashes: Fluoroplastic insulation

-

EMI interference: Braided shielding (P-suffix)

-

Mechanical stress: Steel armor (22-suffix)

-

-

Movement Requirements:

-

Fixed routes: Standard models

-

Dynamic systems: Flexible variants (R-suffix)

-

-

Certifications:

-

Mandatory: Q/AS08.2-2018, GB12666-90

-

International: IEC 60331 (fire), RoHS, REACH

-

Installation Note: Minimum installation temp: -20°C. For >150°C environments, use ceramic spacers. Maintain bending radius to prevent conductor fatigue.

Compliance: Meets Q/AS08.2-2018 electrical/mechanical standards. Halogen-free options available (IEC 60754-1). Custom lengths/colors/configurations offered.