1. Product Overview:

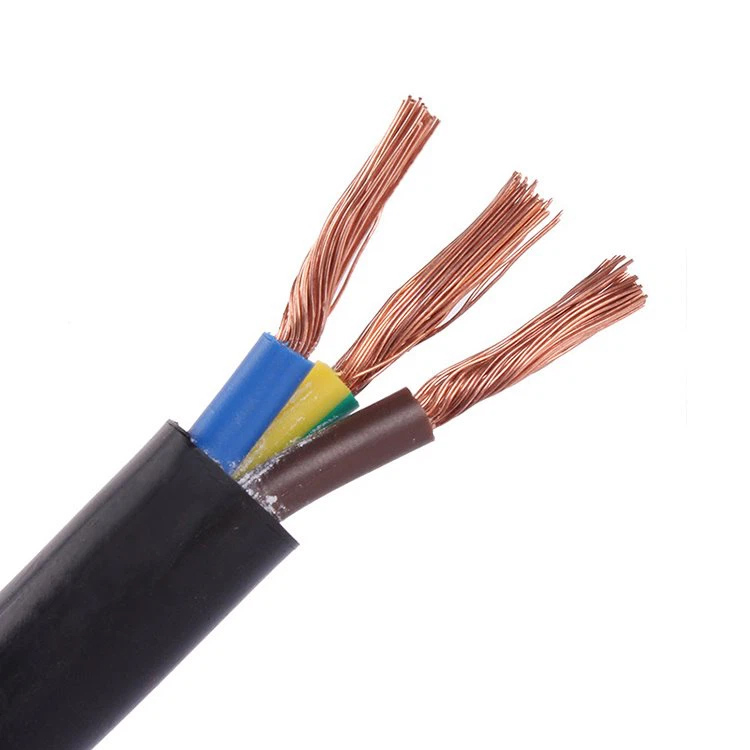

The 0.6/1kV NYY, NYY-J, and NYY-O cables are low voltage, copper conductor power cables featuring Polyvinyl Chloride (PVC) insulation and a PVC outer sheath. Designed for reliable power distribution, these cables offer an economical and robust solution for various fixed installation applications.

2. Key Standards & Approximations:

-

Voltage Rating: 0.6/1 kV (Uo/U)

-

Conforms to Harmonization Document HD 603 S.1 & VDE 0276-1000 (Current Capacity)

-

Manufactured according to VDE 0298-1 (Use of Cables)

-

Compliant with Low Voltage Directive (LVD) 2014/35/EU (CE Marked)

3. Construction:

-

Conductor: Bare Copper

-

re: Circular solid (Single core) -

rm: Circular stranded (Single core) -

sm: Sector-shaped stranded (Multicore)

-

-

Insulation: PVC

-

Bedding (Multicore): PVC

-

Sheath: PVC, Black

-

Core Identification (To VDE 0293):

-

NYY-O: Without Green/Yellow Protective Earth (PE)

-

Single core: Black

-

Two core: Brown, Blue

-

-

NYY-J: With Green/Yellow Protective Earth (PE)

-

Three core: Brown, Blue, Green/Yellow

-

Four core: Black, Grey, Brown, Green/Yellow

-

Five core: Black, Blue, Brown, Grey, Green/Yellow

-

7-40 cores: Black cores (numbered), + Green/Yellow (PE)

-

-

4. Key Technical Parameters:

-

Rated Voltage: 600V / 1000V (Uo/U)

-

Bending Radius:

-

Single Core: Min. 15 x Overall Diameter (O.D.)

-

Multi Core: Min. 12 x Overall Diameter (O.D.)

-

-

Operating Temperature: Standard PVC rating (Typically -5°C to +70°C - refer to specific manufacturer datasheet for exact limits)

5. Material Properties & Advantages:

-

Economical: Cost-effective solution for low voltage power distribution.

-

Durability: PVC insulation and sheath provide good resistance to moisture, abrasion, chemicals, and weathering.

-

Flexibility: Easier handling and installation compared to some alternatives.

-

Flame Retardant: Standard PVC properties (Specific fire performance ratings depend on formulation - check manufacturer specs).

-

Reliability: Proven technology for stable power transmission.

6. Application Scenarios:

-

Fixed Installations: Indoors, Outdoors, Underground (where mechanical damage is not expected), in concrete, in water.

-

Power Distribution Networks: Low voltage mains and submains in residential, commercial, and industrial buildings.

-

Infrastructure: Lighting circuits, HVAC systems, motor control circuits, machine tools, power distribution panels.

-

Suitable Environments: Building sites, construction projects, cable ducts, conduits, cable trays (subject to support requirements).

7. Engineering Selection Data (NYY-J & NYY-O):

| Number of Cores & mm² | Conductor Type | Outer Diameter (mm) | Conductor Weight (kg/km) | Cable Weight (kg/km) |

|---|---|---|---|---|

| NYY-J (With PE) | ||||

| 1x25 | rm | 13.0 | 240.0 | 380 |

| 1x35 | rm | 14.0 | 336.0 | 447 |

| 1x50 | rm | 15.0 | 480.0 | 650 |

| 3x1.5 | re | 12.0 | 43.0 | 223 |

| 4x1.5 | re | 13.0 | 58.0 | 256 |

| 5x1.5 | re | 14.0 | 72.0 | 293 |

| 3x2.5 | re | 13.0 | 72.0 | 272 |

| 4x2.5 | re | 14.0 | 96.0 | 316 |

| 3x4 | re | 15.0 | 115.0 | 373 |

| 4x4 | re | 16.0 | 154.0 | 439 |

| 3x6 | re | 16.0 | 173.0 | 466 |

| 3x10 | re | 18.0 | 288.0 | 629 |

| 4x10 | re | 19.0 | 384.0 | 743 |

| 3x16 | re | 20.0 | 461.0 | 850 |

| 4x16 | re | 22.0 | 614.0 | 1039 |

| 3x25/16 | rm/re | 25.0 | 874.0 | 1595 |

| 4x25 | rm | 27.0 | 960.0 | 1620 |

| 3x35/16 | sm/re | 27.0 | 1162.0 | 1718 |

| 4x35 | sm | 27.0 | 1344.0 | 1916 |

| 3x50/25 | sm/rm | 31.0 | 1680.0 | 2383 |

| ... (See full spec sheet for more sizes) | ... | ... | ... | ... |

| 4x240 | sm | 60.0 | 9216.0 | 11430 |

| NYY-O (Without PE) | ||||

| 1x10 | re | 10.0 | 96.0 | 176 |

| 1x16 | re | 11.0 | 154.0 | 239 |

| 1x25 | rm | 13.0 | 240.0 | 380 |

| 2x1.5 | re | 11.0 | 29.0 | 210 |

| 2x2.5 | re | 12.0 | 48.0 | 250 |

| 2x4 | re | 14.0 | 77.0 | 360 |

| 4x16 | re | 22.0 | 614.0 | 1039 |

| 4x25 | rm | 27.0 | 960.0 | 1620 |

| ... (See full spec sheet for more sizes) | ... | ... | ... | ... |

| 1x500 | rm | 39.0 | 4800.0 | 5400 |

(Note: re = Solid Circular, rm = Stranded Circular, sm = Stranded Sector-shaped. Weights are approximate. Full specification sheet required for all available sizes and configurations.)

8. Installation Notes:

-

Suitable for direct burial, installation in ducts, conduits, or on cable trays.

-

Adhere strictly to minimum bending radii during installation to prevent damage.

-

Ensure correct core identification for safe and compliant electrical connections.

-

Installation should be performed in accordance with local regulations and electrical codes (e.g., IEC 60364, national wiring rules).