N2XSY & N2XSRY Single-Core Medium Voltage Cables

Product Overview

Engineered for critical power distribution in industrial, utility, and infrastructure projects, IEC 60502-compliant single-core MV cables deliver reliable performance from 1.8/3kV to 26/35kV. Featuring XLPE or EPR/HEPR insulation with optional aluminum/steel armor, these cables are designed for indoor/outdoor, duct, tray, direct burial, and submerged installations.

Key Features & Benefits

-

Voltage Range: 1.8/3kV to 26/35kV (Um: 3.6–42kV)

-

Triple-Extrusion Bonding: Void-free conductor screen-insulation-insulation screen interface.

-

Cold-Strippable Screens: Easy termination (min. 0.3mm; max. 500 Ω·m at 90°C).

-

Armor Options: Aluminum (N2XSRY) or steel wire armor for mechanical protection.

-

Flexible Installation: Suitable for ducts, trays, direct burial, and aquatic environments.

-

Certified: Compliant with IEC 60502-1/2, CE, ISO 9001.

Construction & Technical Specifications

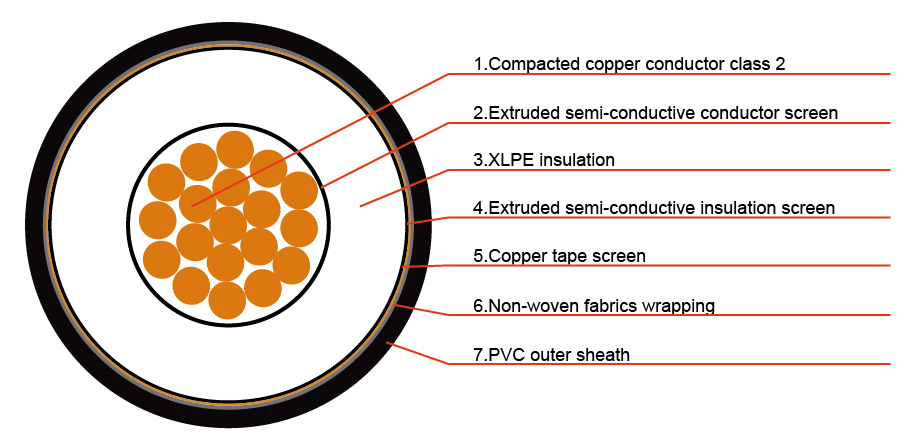

Layer-by-Layer Structure:

| Component | Specification | Standard |

|---|---|---|

| Conductor | Plain annealed copper/aluminum (Class 1/2) | IEC 60228 |

| Conductor Screen | Extruded semi-conducting compound (bonded to insulation; omitted for ≤3.6/6kV PVC/EPR) | IEC 60502 |

| Insulation | XLPE or EPR/HEPR (Thickness per Table 1) | IEC 60502 |

| Insulation Screen | Cold-strippable semi-conducting layer + optional tape (min. 0.3mm) | IEC 60502 |

| Metallic Screen | Copper tape/wire (Min. cross-section: Table 2) | IEC 60502 |

| Armor | Aluminum round wire (N2XSRY) or steel wire (diameter per Table 3) | IEC 60502 |

| Outer Sheath | PVC, PE, CSP, or chlorosulfonated PE (Thickness: 0.035D + 1.0mm) | IEC 60502 |

Critical Parameters:

Table 1: Insulation Thickness (XLPE/EPR)

| Voltage (Uo/U) | 50mm² | 240mm² | 630mm² |

|---|---|---|---|

| 1.8/3kV | 2.5 mm | 2.6 mm | 3.4 mm |

| 8.7/15kV | 4.5 mm | 4.5 mm | 4.5 mm |

| 26/35kV | 10.5 mm | 10.5 mm | 10.5 mm |

Table 2: Metallic Screen Cross-Section

| Conductor Size (mm²) | Min. Screen (mm²) |

|---|---|

| ≤120 | 16 |

| 400–630 | 35 |

| 1000 | 50 |

Material Properties & Performance

| Property | Specification |

|---|---|

| Operating Temp. | 90°C (XLPE/EPR); 70°C (PVC) |

| Short-Circuit Temp. | 250°C (XLPE/EPR, 1-sec); 160°C (PVC, 1-sec) |

| Bending Radius | 12 × Overall Diameter |

| Cold Resistance | -5°C (PVC sheath); -20°C (PE sheath) |

| Voltage Test | 30.5kV AC (8.7/15kV); 91kV AC (26/35kV) per IEC 60502 |

Application Scenarios

-

Power Stations: Switchgear connections, transformer feeds.

-

Industrial Plants: Heavy machinery, mining operations, manufacturing.

-

Renewable Energy: Wind/solar farm grid connections.

-

Infrastructure: Underground networks, bridges, tunnels.

-

Marine Environments: Ports, offshore platforms (aluminum armor for corrosion resistance).

Engineering Selection Guide

1. Voltage & Insulation Selection:

| Application | Recommendation |

|---|---|

| Standard industrial | 8.7/15kV XLPE |

| High-voltage transmission | 26/35kV XLPE/EPR |

| High flexibility needed | EPR/HEPR insulation |

2. Armor Type:

-

N2XSRY (Al): Corrosive environments (marine, chemical plants).

-

Steel Armor: High-impact zones (mining, construction).

3. Current Ratings (Representative 90°C XLPE):

| Size | Buried (A) | Duct (A) | Air-Trefoil (A) |

|---|---|---|---|

| 240mm² | 469 (Cu) | 447 (Cu) | 641 (Cu) |

| 630mm² | 700 (Cu) | 654 (Cu) | 1045 (Cu) |

*Full EPR/XLPE current tables available in datasheet. Conditions: 20°C ground, 1.5 K·m/W thermal resistivity.*

Dimensional & Electrical Data (26/35kV Copper Example)

| Size | OD (mm) | Weight (kg/km) | Capacitance (pF/m) | Charging Current (mA/m) |

|---|---|---|---|---|

| 150mm² | 44.9 | 2,923 | 169 | 1.36 |

| 400mm² | 54.9 | 5,704 | 227 | 1.80 |

Certifications & Packaging

-

Standards: IEC 60502-1 (1.8/3kV), IEC 60502-2 (3.6/6–26/35kV).

-

Certifications: CE, ISO 9001.

-

Packaging: Fumigated steel-wood drums (1,000m/2,000m standard lengths).

-

Shipping: FOB/CIF/C&F from Qingdao or designated ports. Bulk discounts available.