Medium Voltage Three-Core Power Cables

Product Overview

Engineered for reliable power distribution in demanding environments, our IEC 60502-compliant medium voltage cables deliver exceptional performance across industrial, utility, and infrastructure applications. Available in voltage ratings from 1.8/3kV to 26/35kV, these three-core cables feature robust construction with optional armor for enhanced mechanical protection and are designed for indoor/outdoor, underground, cable tray, and aquatic installations.

Key Features & Benefits

-

Wide Voltage Range: Suitable for systems from 1.8/3kV to 26/35kV (50Hz).

-

Triple-Extrusion Technology: Ensures void-free bonding of conductor screen, insulation, and insulation screen.

-

Flexible Installation: Compatible with ducts, trays, direct burial, and submerged environments.

-

Advanced Materials: XLPE/EPR insulation for thermal stability, cold-strippable screens for easy termination.

-

Armor Options: Steel wire/tape armor (round or flat) for crush/impact resistance (UL 2225 equivalent).

-

Certified Reliability: Compliant with IEC 60502-1 & -2, CE, and ISO 9001.

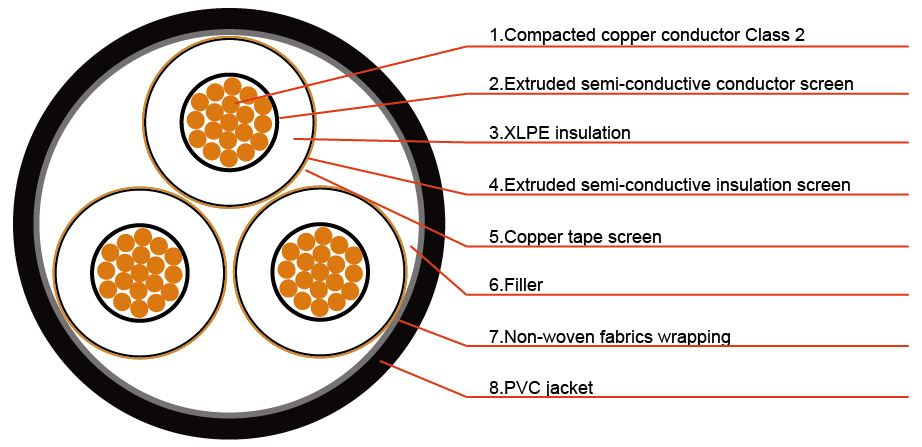

Construction & Technical Specifications

Core Components:

| Layer | Material & Specifications | Standards |

|---|---|---|

| Conductor | Plain annealed copper/aluminum (Class 1/2) | IEC 60228 |

| Conductor Screen | Extruded non-metallic semi-conducting compound (excludes voids; hand-strippable) | IEC 60502 |

| Insulation | XLPE, EPR/HEPR, or PVC (Thickness per Table 1) | IEC 60502 |

| Insulation Screen | Cold-strippable semi-conducting layer (min. 0.3mm; max. 500 Ω·m at 90°C) | IEC 60502 |

| Metallic Layer | Copper tape/wire screen, concentric conductor, lead sheath, or armor (Min. cross-section: Table 3) | IEC 60502 |

| Outer Sheath | PVC (ST3), PE (ST7), CSP, or chlorosulfonated PE (Thickness: 0.035D + 1.0mm) | IEC 60502 |

Critical Tables:

Table 1: Insulation Thickness (XLPE/EPR)

| Core Section (mm²) | 1.8/3kV | 6/10kV | 12/20kV | 26/35kV |

|---|---|---|---|---|

| 50–185 | 2.5 mm | 3.4 mm | 5.5 mm | 10.5 mm |

| 240 | 2.6 mm | 4.5 mm | 5.5 mm | 10.5 mm |

| 500–1600 | 3.2 mm | 4.5 mm | 5.5 mm | 10.5 mm |

Table 3: Metallic Screen Cross-Section

| Core Section (mm²) | Min. Screen Area (mm²) |

|---|---|

| ≤120 | 16 |

| 400–630 | 35 |

| 800–1000 | 50 |

Application Scenarios

-

Power Distribution: Switchgear, substations, and utility networks.

-

Industrial Plants: Mining, manufacturing, and processing facilities.

-

Infrastructure: Cable ducts, underground conduits, and aquatic installations.

-

Renewable Energy: Wind/solar farms requiring MV power transmission.

-

Harsh Environments: Chemical exposure, UV radiation, and temperature extremes (-40°C to 90°C).

Engineering Selection Guide

1. Voltage Selection:

-

Use 1.8/3kV for light industrial loads.

-

Specify 26/35kV for high-voltage transmission (e.g., grid interconnections).

2. Armor Requirement:

| Environment | Recommendation |

|---|---|

| Exposed/mechanical risk areas | Steel wire/tape armor |

| Protected ducts/trays | Unarmored + PVC sheath |

3. Conductor Type:

-

Copper: High conductivity, termination reliability.

-

Aluminum: Cost-effective for long runs (30% lighter).

4. Insulation Material:

-

XLPE: Superior thermal resistance (90°C operational).

-

EPR/HEPR: Enhanced flexibility for dynamic installations.

Dimensional Data (Summary)

Three-Core 8.7/15kV Unarmored (Copper):

| Section (mm²) | OD (mm) | Weight (kg/km) |

|---|---|---|

| 95 | 57 | 4,700 |

| 240 | 74 | 9,820 |

Three-Core 26/35kV Armored (Copper):

| Section (mm²) | OD (mm) | Weight (kg/km) |

|---|---|---|

| 150 | 108.5 | 17,420 |

| 400 | 129 | 29,200 |

Full dimensional tables available in technical datasheet.

Certifications & Packaging

-

Certifications: CE, ISO 9001.

-

Packaging: Fumigated steel-wood drums (standard: 1,000m/2,000m lengths).

-

Shipping: FOB/CIF/C&F options; bulk discounts available.