N2XSY 6/10kV Medium Voltage Cables

Product Overview:

Engineered for reliable power distribution in demanding industrial environments, the N2XSY 6/10kV cable delivers superior performance under DIN VDE 0276-620, HD 620, and EN 60228 standards. Featuring XLPE insulation, copper screening, and flame-retardant PVC sheath, this cable is designed for direct burial, duct installation, and industrial plant applications where safety and durability are critical.

Key Features & Benefits

-

Robust Construction: XLPE insulation + dual semi-conductive layers ensure electrical integrity

-

Flame Retardancy: Complies with IEC/EN 60332-1-2 for enhanced fire safety

-

Wide Temp Range: -20°C to +70°C (operational), -5°C to +70°C (flexed)

-

Short-Circuit Resilience: Withstands 250°C conductor temperatures (1-sec fault)

-

Easy Installation: 15×OD bending radius for confined spaces

-

Certified Reliability: CE and ISO 9001 certified

Technical Specifications

| Parameter | Specification | Standard |

|---|---|---|

| Rated Voltage | 6/10kV (Um=12kV) | DIN VDE 0276-620 |

| Test Voltage | 21 kV AC | EN 60228 |

| Conductor | Compacted copper (Class 2) | IEC 60228 |

| Insulation | XLPE (Cross-Linked Polyethylene) | HD 620 |

| Screen | Copper wires + copper tape wrapping | IEC 60502-2 |

| Sheath | PVC (Red) / HDPE (optional) | IEC 60332-1-2 |

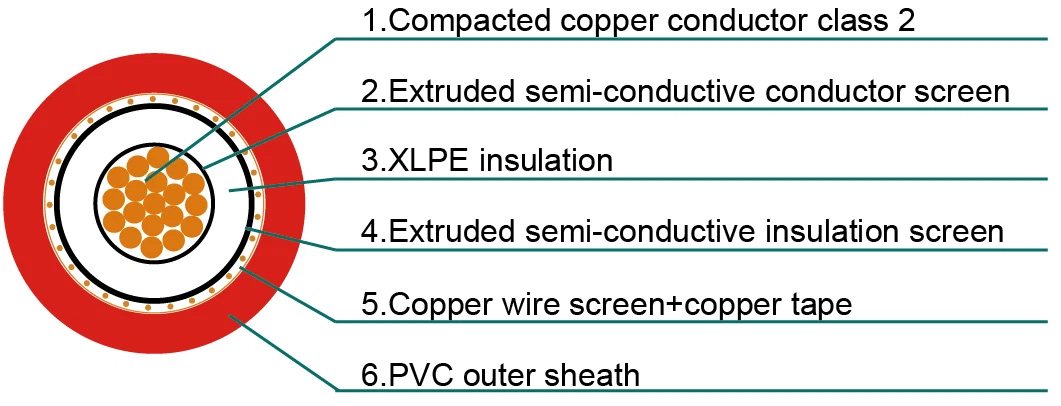

Construction Details

Layer-by-Layer Structure:

-

Conductor: Stranded, compacted copper (Class 2 per IEC 60228)

-

Conductor Screen: Extruded semi-conductive compound

-

Insulation: XLPE for thermal stability (90°C continuous)

-

Insulation Screen: Cold-strippable semi-conductive layer

-

Metallic Screen: Copper wire braid + helical copper tape

-

Outer Sheath: Flame-retardant PVC (standard red)

Technical Data Table (6/10kV Configuration)

| Cross Section [mm²] | Insul. Thick. [mm] | Screen [mm²] | Sheath Thick. [mm] | Min. OD [mm] | Max. OD [mm] | Weight [kg/km] | Buried Current [A]* | Air Current† [A] |

|---|---|---|---|---|---|---|---|---|

| 35 | 3.4 | 16 | 2.5 | 23.0 | 28.0 | 900 | 187 | 197 |

| 50 | 3.4 | 16 | 2.5 | 24.0 | 29.0 | 1050 | 220 | 236 |

| 70 | 3.4 | 16 | 2.5 | 26.0 | 31.0 | 1300 | 268 | 294 |

| 95 | 3.4 | 16 | 2.5 | 26.0 | 32.0 | 1600 | 320 | 358 |

| 120 | 3.4 | 16 | 2.5 | 28.0 | 34.0 | 1850 | 363 | 413 |

| 150 | 3.4 | 25 | 2.5 | 29.0 | 35.0 | 2200 | 405 | 468 |

* Buried current rating: Direct burial in ground at 20°C soil temperature, trefoil formation

† Air current rating: Laid in air at 30°C ambient, trefoil formation

Application Scenarios

-

Power Distribution Networks: Substation connections, grid feeders

-

Industrial Plants: Motor feeds, conveyor systems, heavy machinery

-

Renewable Energy: Wind turbine inter-array cabling

-

Infrastructure: Underground ducts, tunnels, cable trays

-

Hazardous Areas: Chemical plants, refineries (flame-retardant design)

Engineering Selection Guide

| Selection Factor | Technical Guidance |

|---|---|

| Current Capacity | 150mm² supports 468A in air (30°C trefoil) |

| Mechanical Protection | 2.5mm PVC sheath + copper screen for impact zones |

| Voltage Drop | ≤3% with 95mm² @ 200m run (400V system) |

| Environmental Exposure | Use HDPE sheath alternative for UV/abrasion zones |

Certifications & Packaging

-

Standards: DIN VDE 0276-620, HD 620, EN 60228, IEC/EN 60332-1-2

-

Certifications: CE, ISO 9001

-

Packaging: Fumigated steel-wood drums (1,000m/2,000m lengths)

-

Customization: Sheath color (red standard), HDPE option available