Product Overview:

This 600V 16mm² (6 AWG) 2-Core Stranded Aluminum SEU Service Entrance Cable features an Aluminum Concentric Neutral and premium XHHW-2 Insulation, providing a cost-effective solution for service entrance and panel feeder applications in residential and commercial buildings. Manufactured to UL 854 standards, it utilizes stranded aluminum for both phase and neutral conductors, clad in robust XHHW-2 insulation for superior thermal performance and durability.

Key Technical Specifications

| Parameter | Specification | Standard |

|---|---|---|

| Voltage Rating | 600 Volts | UL 854 |

| Phase Conductors | Compact Stranded Aluminum (AA-8000 Series Alloy) | ASTM B800 |

| Conductor Size | 16 mm² (Approx. 6 AWG) - (2 Conductors) | |

| Neutral Conductor | Bare Concentric Stranded Aluminum (AA-8000 Series) | ASTM B800, UL 854 |

| Neutral Function | Serves as Grounded Neutral Conductor. Separate EGC required per NEC for SEU with Al Neutral. | NEC 338.108(B) |

| Insulation | Cross-linked Polyethylene (XLPE) - XHHW-2 | UL 44, UL 854 |

| Insulation Color | Black (Standard) | |

| Overall Jacket | Integrated SEU Construction (No Separate Jacket) | UL 854 |

| Temperature | -40°C to +90°C (Conductor) / -40°C to +90°C Wet or Dry (Insulation) | UL 854, UL 44 |

| Flame Rating | Passes UL VW-1 Vertical Flame Test | UL 1581 |

| Sunlight Res. | Excellent (XHHW-2 Rating) | UL 44, UL 854 |

| Certification | UL Listed (Marked on Cable) |

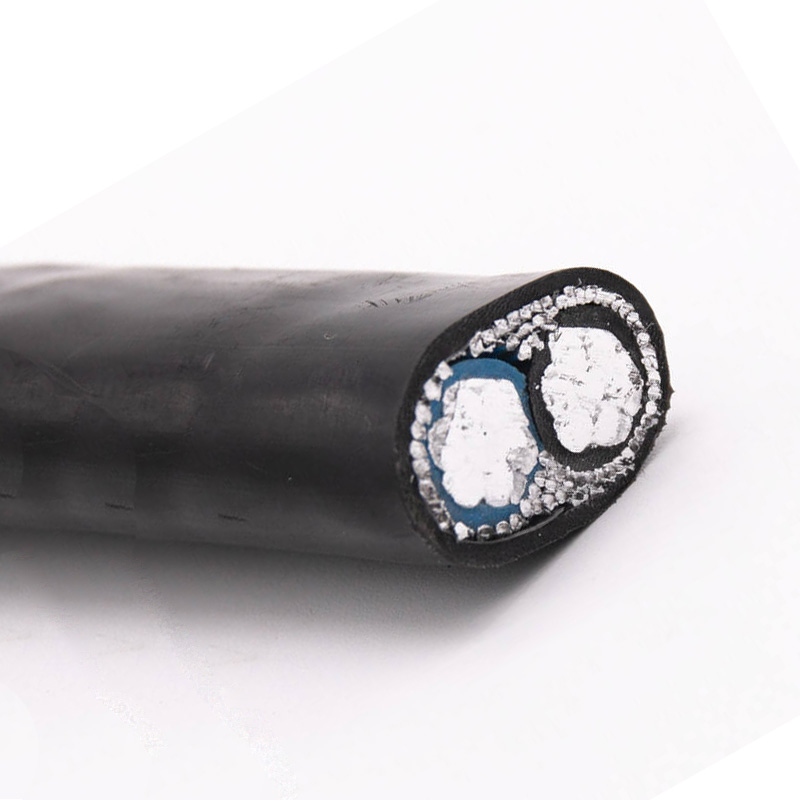

Product Structure

-

Phase Conductors (2):

-

Compact stranded AA-1350 or AA-8000 series aluminum alloy.

-

Nominal Cross-Section: 16mm² (6 AWG).

-

Stranding improves flexibility for installation.

-

-

Insulation:

-

Material: Cross-linked Polyethylene (XLPE).

-

Type: XHHW-2. Provides:

-

High Heat Resistance (90°C Wet/Dry).

-

Excellent Moisture, Chemical, and Oil Resistance.

-

Superior Sunlight (UV) Resistance and Physical Damage (Crush/Impact) Resistance.

-

High Dielectric Strength.

-

-

-

Neutral Conductor:

-

Bare, stranded AA-1350 or AA-8000 series aluminum alloy wires.

-

Applied concentrically in a reverse-lay spiral around the insulated phase conductors.

-

Note: This concentric neutral serves only as the Grounded (Current-Carrying) Neutral Conductor. It does not qualify as the Equipment Grounding Conductor (EGC) under the NEC when made of aluminum for SEU cable. A separate EGC is required.

-

-

Overall Construction (SEU Style):

-

The insulated phase conductors and bare concentric aluminum neutral are cabled together into a flat, oval configuration.

-

Characteristic of Type SE, Style U (SEU).

-

No separate overall jacket; the assembly forms the cable core.

-

Material Characteristics & Advantages

-

Cost Efficiency: Aluminum conductors (both phase and neutral) offer significant material cost savings compared to copper solutions.

-

Weight Savings: Aluminum reduces cable weight, simplifying handling and support requirements.

-

Modern Alloys (AA-8000 Series): Mitigate historical concerns regarding aluminum (creep, connection reliability) when installed correctly using AL-rated components and procedures.

-

Premium XHHW-2 Insulation:

-

Outstanding thermal stability across a wide range (-40°C to +90°C).

-

Superior resistance to environmental stressors: moisture, UV, chemicals, oils.

-

Enhanced toughness and abrasion resistance versus PVC.

-

High dielectric strength ensures electrical integrity.

-

Passes stringent flame retardancy tests (VW-1).

-

-

SEU Profile: Flat, oval shape facilitates easier termination at meter bases and panels compared to round cables.

Primary Application Scenarios

-

Service Entrance Conductors: Above-ground connections from the utility meter base to the main electrical distribution panel (within NEC distance limits), primarily where the utility requires or permits an aluminum concentric neutral.

-

Panel Feeders: Distributing power from main panels to subpanels within buildings, utilizing aluminum for cost savings on longer runs.

-

Branch Circuits: Where Type SE cable is permitted by code and an aluminum neutral is acceptable/specified.

-

Commercial Buildings & Multi-Dwelling Units (MDUs): Economical feeder installations for lighting and power distribution.

-

Dry and Damp Locations: Suitable for indoor use and protected outdoor locations (e.g., under eaves, within service entrance hoods). Not rated for direct burial or continuous unsupported outdoor exposure.

-

Conduit Use: Can be pulled into conduit for sections requiring physical protection (strictly adhere to conduit fill rules and bending radii).

Critical Engineering Selection Considerations

-

Equipment Grounding Conductor (EGC): CRITICAL: Per NEC 338.108(B), the concentric neutral in Type SE cable constructed with aluminum cannot be used as an Equipment Grounding Conductor. A separate copper or aluminum Equipment Grounding Conductor (EGC) MUST be installed within the raceway or cable assembly alongside the SEU cable. Failure to provide a separate EGC is a code violation and a serious safety hazard.

-

Ampacity: Refer to NEC Table 310.16. Use the 75°C column (assuming terminations are rated 75°C). Apply derating factors for ambient temperature (>30°C) and conductor bundling (>3 current-carrying conductors). Remember the neutral is current-carrying.

-

Voltage Drop: Calculate voltage drop for the run length using aluminum conductor properties to ensure compliance with system requirements. Aluminum has higher resistance than copper for the same cross-sectional area.

-

Terminations:

-

Aluminum Conductors (Phase & Neutral): MUST use connectors specifically listed and marked for AL/CU or AL9. Terminate to devices (lugs, breakers, busbars) explicitly rated for aluminum wire. Follow manufacturer's torque specifications precisely. Apply an antioxidant compound suitable for aluminum conductors to all termination points.

-

-

Installation: Install per NEC Article 338. Maintain minimum bending radii to avoid damaging conductors. Protect from physical damage. Not for direct burial. Ensure proper support.

-

Code Compliance: Strictly adhere to NEC Article 338 and all applicable local amendments. Pay particular attention to the requirement for a separate EGC (338.108(B)).