Premium Silicone Rubber High Voltage Cable (20KV to 100KV) - Braided Shield for Automotive & Industrial Use

![]()

Product Overview

Engineered for demanding high-voltage applications, this Silicone Rubber Braided Shield HV Cable delivers exceptional electrical performance, safety, and longevity. Designed to withstand extreme electrical stress and harsh environments, it is the ideal solution for automotive ignition systems, industrial test equipment, appliances, and instrumentation requiring reliable power transmission up to 100KV AC / 200KV DC.

Key Features & Benefits

-

Ultra-High Voltage Rating: Certified for AC 3KV-100KV / DC up to 200KV (conductor to outermost insulation).

-

Superior Insulation: High-purity, non-toxic, odorless silicone rubber offers exceptional thermal stability (-60°C to +200°C), flexibility, and 20,000+ hour aging resistance.

-

EMI/RFI Suppression: Tinned copper braided shield minimizes corona discharge and electromagnetic interference.

-

Conductor Options: Tinned copper or bare copper in 1.5mm² (15AWG), 2.5mm² (13AWG), 4.0mm² (11AWG).

-

Automotive Grade: SAE J1678 compliance for ignition systems, oil/fuel resistance.

-

Safety Certified: RoHS/REACH compliant, flame-retardant (UL94 V-0).

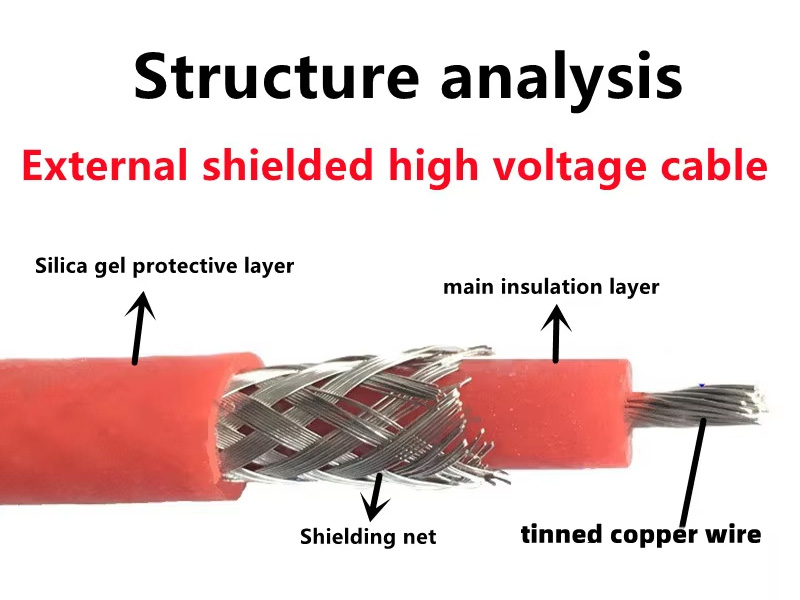

Construction & Materials

-

Conductor: High-conductivity tinned copper/bare copper.

-

Insulation: Premium silicone rubber (UL 1441 certified).

-

Shielding: Tinned copper braid (≥85% coverage).

-

Internal Shield: Over conductor, under main insulation

-

Outer Shield: Over main insulation

-

-

Jacket: Silicone rubber (outer shield designs).

Technical Specifications

Voltage rating = conductor to outermost insulation withstand voltage.

| Shield Type | Conductor Size | AWG | OD (mm) | Max. AC (kV) | Max. DC (kV) |

|---|---|---|---|---|---|

| Internal | 1.5mm² | 15AWG | 7.0 | 20 | 60 |

| Internal | 1.5mm² | 15AWG | 9.0 | 30 | 100 |

| Internal | 2.5mm² | 13AWG | 14.0 | 50 | 150 |

| Internal | 2.5mm² | 13AWG | 16.0 | 60 | 150 |

| Outer | 1.5mm² | 15AWG | 6.5 | 10 | 30 |

| Outer | 1.5mm² | 15AWG | 12.0 | 20 | 60 |

| Outer | 2.5mm² | 13AWG | 24.0 | 50 | 100 |

| Outer | 2.5mm² | 13AWG | 30.0 | 60 | 150 |

| Outer | 4.0mm² | 11AWG | 35.0 | 100 | 200 |

Engineering Notes

-

Shielding Function: Conductor and shield operate in parallel to suppress corona discharge.

-

Connection Protocol: Braid electrically bonded to conductor - NOT designed for grounding.

-

Testing Standard: Hi-pot tested per IEC 60243 at 1.5x rated voltage (elevated ground plane).

-

Bending Radius: ≥6x OD for dynamic applications.

-

Current Ratings: 1.5mm²=10A | 2.5mm²=16A | 4mm²=25A (@ 90°C)

Applications

-

Automotive: Ignition systems (coil/plug wires), EV battery monitoring.

-

Industrial: HV test benches, power supplies, neon transformers.

-

High-Power Appliances: Industrial microwave generators, heating elements.

-

Medical/Energy: X-ray equipment, solar inverter connections.

-

High-Voltage Labs: Probe leads, divider connections.

Selection Guidance

🔸 Internal Shield – Optimal for compact spaces (e.g., ignition coils)

🔸 Outer Shield – Superior mechanical protection (e.g., test equipment)

🔸 Conductor Size – Match current load requirements

Compliance & Standards

-

Voltage: IEC 60885 / IEEE 400

-

Ignition: SAE J1678

-

Flame: UL 224 VW-1

-

Environmental: IP67 (jacketed types)