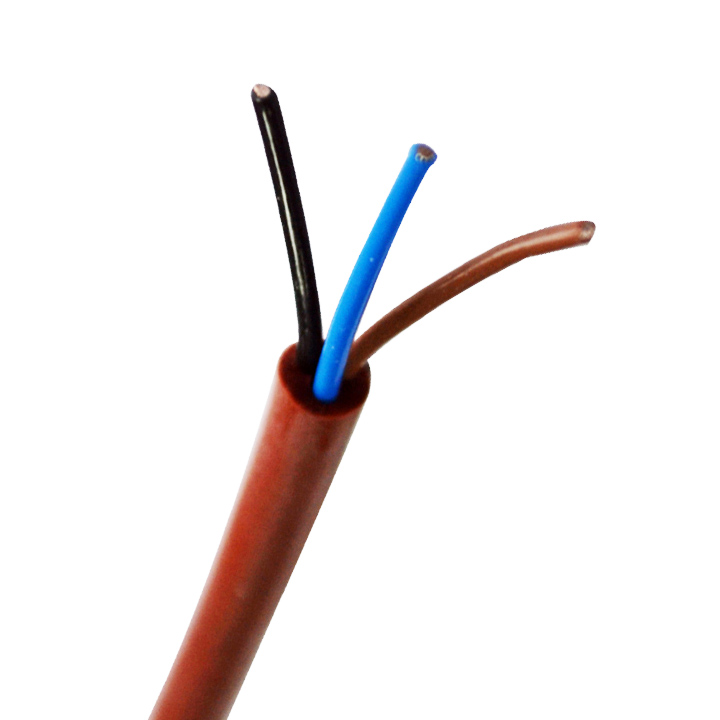

YFG Series High-Temperature Resistance Wire with FEP Insulation & Silicone Jacket

Product Overview

Engineered for extreme environments, this triple-layer shielded cable combines FEP insulation and silicone jacketing to deliver unmatched thermal stability (-60°C to +200°C), chemical resistance, and flexibility. Ideal for high-heat industrial applications requiring reliable power transmission under 500V.

Key Features & Benefits

-

Extreme Temperature Range: Continuous operation at +180°C, intermittent up to +200°C

-

Triple-Shielded Protection:

-

Tin-plated copper conductor (anti-oxidation)

-

FEP insulation (fluoropolymer dielectric)

-

Silicone outer jacket (mechanical/chemical protection)

-

-

Chemical Resistance: Withstands acids, alkalis, oils, and fungi (per IEC 60811-2-1)

-

Flexible & Durable: 50,000+ bend cycles (IEC 60227-1)

-

Safety Certified: UL 3271 / CSA AWM 21098

Construction & Materials

| Layer | Material Specification | Function |

|---|---|---|

| Conductor | Stranded tin-plated copper (20AWG) | Low-resistance current carrier |

| Insulation | FEP Fluoropolymer (0.3mm nominal thickness) | Dielectric strength + chemical barrier |

| Jacket | Silicone Rubber (0.8mm nominal thickness) | Thermal/mechanical protection |

Technical Specifications

| Parameter | Specification | Standard |

|---|---|---|

| Rated Voltage | 300/500V | IEC 60227 |

| Temperature Range | -60°C to +200°C (intermittent) | UL 758 |

| Conductor Size | 20AWG (0.52mm²) / 20/0.18 strands | ASTM B-33 |

| Insulation Resistance | ≥100 MΩ·km (20°C) | IEC 60167 |

| Outer Diameter (OD) | 2.5±0.2mm | - |

| Flammability Rating | VW-1 (UL 1581) | - |

Full Size Range:

| AWG | Stranding | Cross-section (mm²) | OD (mm) | Packaging (M) |

|---|---|---|---|---|

| 16 | 52/0.18 | 1.31 | 2.50 | 305 |

| 18 | 30/0.18 | 0.76 | 2.17 | 305 |

| 20 | 20/0.18 | 0.52 | 1.91 | 305 |

| 22 | 12/0.18 | 0.31 | 1.76 | 305 |

| 24 | 11/0.16 | 0.22 | 1.60 | 305 |

Engineering Advantages

-

Dielectric Strength: 6kV/mm (FEP) vs. 3kV/mm (standard PVC)

-

Thermal Endurance: 20,000 hrs @ 200°C (IEC 60216)

-

Chemical Performance: Resists concentrated acids/alkalis (pH 1-14)

-

Flexibility: Bending radius ≤4×OD at -60°C

Applications

-

Industrial Heating: Furnace wiring, thermocouple extensions

-

Power Generation: Turbine sensors, boiler control systems

-

Robotics: Automated assembly lines (automotive/steel plants)

-

Appliances: Industrial microwaves, commercial ovens

-

Critical Infrastructure: Chemical processing equipment, offshore platforms

Selection Guidance

High-Chemical Exposure: Use FEP/silicone combo (superior to PTFE)

Dynamic Flexing: Select 20AWG+ for repeated motion

Color Coding: 9 standard colors (red/yellow/blue/white/black/green/brown)

Compliance & Certifications

-

Electrical: IEC 60227, EN 50525-2-81

-

Fire Safety: UL 1685 FT4/IEEE 1202

-

Material: RoHS 3, REACH SVHC

-

International: CSA C22.2 No. 210