Product Overview

SiHF/GL-P Heat-Resistant Halogen-Free Steel Braided Silicone Multicore Cable is engineered for extreme thermal and mechanical stress environments. Featuring dual-layer silicone insulation, galvanized steel wire braiding, and glass fiber reinforcement, this cable operates continuously at 180°C (250°C short-circuit) while resisting oils, chemicals, and radiation. Compliant with DIN/VDE and IEC standards, it ensures signal integrity in power stations, steel mills, and mobile industrial equipment.

Key Features

-

Voltage Rating: 0.6/1KV AC (300/500V per DIN VDE 0285)

-

Temperature Range:

-

Continuous: -60°C to +180°C (conductor)

-

Short-term: +220°C (operation), +250°C (5s short-circuit)

-

-

Halogen-Free: Zero toxic emissions during combustion

-

Shielding: Galvanized steel wire braid + glass fiber tape

-

Mechanical Protection: Crush/cut resistance (20 Mrad radiation proof)

-

Flame Safety: IEC 60332-1-2 compliant (no flame propagation)

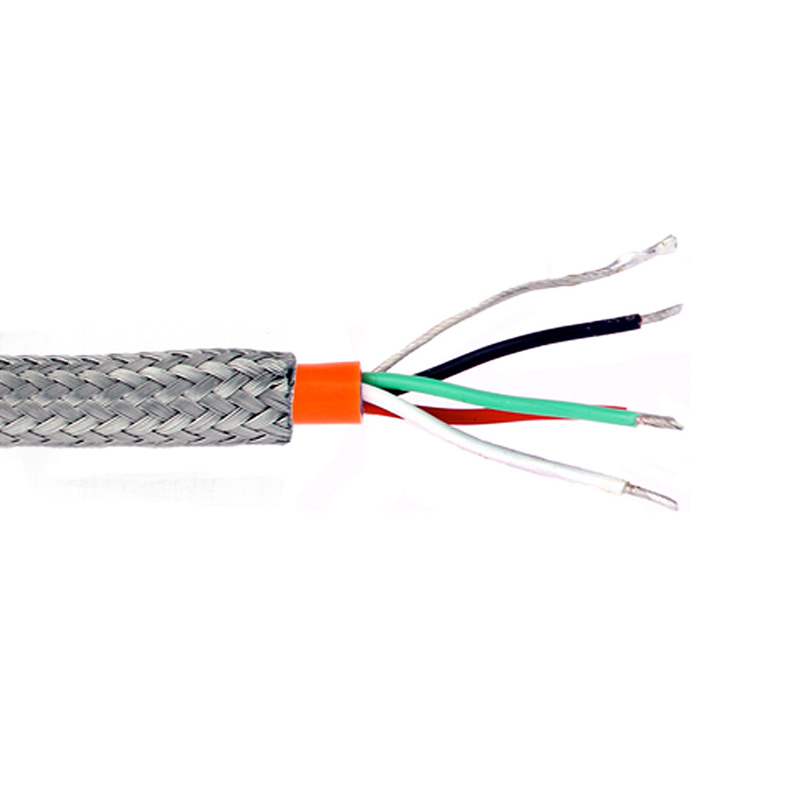

Cable Structure & Materials

| Layer | Material/Construction | Function & Properties |

|---|---|---|

| Conductor | Tinned copper (DIN VDE 0295 Cl.5) | Fine-stranded, oxygen-resistant, IEC 60228 Class 5 |

| Insulation | Silicone rubber | Thermal stability (-60°C~+180°C), ozone resistant |

| Core Identification | Colored (≤5 cores) / Numbered (≥6) | DIN VDE 0293-308 compliant, includes green-yellow ground |

| Core Layering | Optimized stranding | Reduced crosstalk, uniform flexibility |

| Inner Sheath | Silicone rubber | Halogen-free, acid/alkali resistant |

| Reinforcement | Glass fiber tape | Thermal barrier, mechanical protection |

| Outer Braiding | Galvanized steel wire | EMI shielding, tensile strength (150+ N/mm²) |

Technical Parameters

| Parameter | Value | Standard |

|---|---|---|

| Electrical | ||

| Test Voltage | 2,000V AC | DIN VDE 0482 |

| Breakdown Voltage | ≥5,000V | IEC 60243 |

| Insulation Resistance | ≥200 MΩ·km | IEC 60167 |

| Capacitance | ≤120 nF/km | IEC 60502-1 |

| Mechanical | ||

| Bending Radius | Fixed: 5× OD Flexing: 10× OD |

ISO 6722 |

| Conductor Sizes | 0.75mm² - 10mm² (20-10 AWG) | DIN VDE 0295 |

| Radiation Resistance | 20 Mrad (200 kGy) | IEC 60544 |

| Thermal | ||

| Power Derating | 155°C: 91% load 175°C: 41% load |

DIN VDE 0100 |

Material Advantages

-

Silicone Rubber Insulation/Sheath:

-

Maintains elasticity from -60°C to +180°C

-

Forms protective SiO₂ layer at 350°C+

-

Resists oils, alcohols, diluted acids, ozone, and UV

-

-

Steel Wire Braid:

-

360° EMI shielding (>65dB attenuation)

-

Cut/crush protection for heavy industrial use

-

-

Glass Fiber Tape: Prevents sheath melting at extreme temperatures

Application Scenarios

-

Extreme Heat Industries:

-

Steel mills, foundries, glass factories, cement kilns (up to 250°C)

-

-

Energy & Infrastructure:

-

Power station control systems, turbine wiring, reactor instrumentation

-

-

Mobile Machinery:

-

Furnace trolleys, hot-rolling mill conveyors, crane electrification

-

-

Transportation:

-

Ship engine rooms, aircraft galleys, locomotive wiring

-

-

Hazardous Areas:

-

Chemical plants (acid/alkali resistance), nuclear facilities (radiation proof)

-

Compliance & Standards

| Standard | Certification | Scope |

|---|---|---|

| Electrical | DIN VDE 0250-1, DIN EN 50525-2-83 | 300/500V multicore cable construction |

| Fire Safety | IEC 60332-1-2 (no flame propagation) | Vertical flame spread |

| Halogen-Free | IEC 60754-2 (DIN VDE 0482-267) | Low corrosivity of combustion gases |

| Environmental | RoHS 3, REACH SVHC-free | Hazardous substance compliance |

| International | CE (2006/95/EC Low-Voltage Directive) | EU market access |

Installation Guidelines

-

Fixed Installations Only: Open/ventilated ducts or pipes

-

Critical Note: Avoid enclosed spaces >90°C (reduced mechanical properties)

-

Bending Radius:

-

Fixed: ≥5× cable outer diameter

-

Dynamic: ≥10× cable outer diameter

-

Ordering Information

Base Model: SiHF/GL-P

Options:

-

Conductor: Tinned copper (standard), bare copper (optional)

-

Core Configuration: 2-37 cores (0.75-10mm²)

-

Identification:

-

G: With green-yellow ground conductor

-

X: Without ground conductor

-

-

Special Variants: UV-resistant, oil-immersion grade

Example Part Numbers:

23062: 2×0.75mm², OD 7.9mm, 90kg/km

23091: 7×4mm², OD 17.4mm, 240kg/km

Engineering Tip: For vertical runs >30m, use cable trays with 5×OD support intervals to prevent tensile stress.