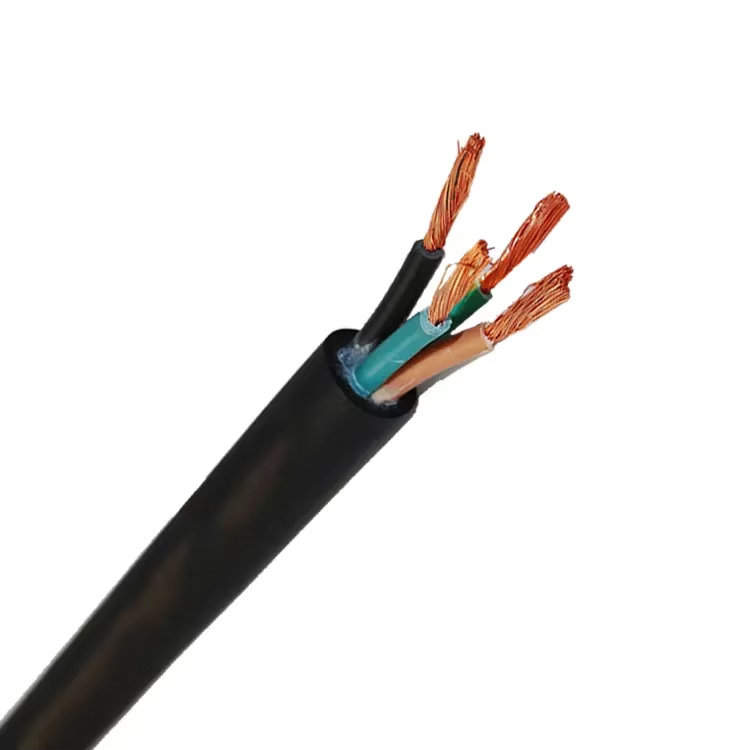

UL 1277 Type TC-ER Tray Cable

Product Overview

This UL 1277 certified Type TC-ER cable delivers robust power and control solutions for industrial cable tray systems. Engineered with XLPE or PVC insulation and crush-resistant construction, it meets NEC Article 318/340 requirements for 600V applications in dry (90°C) and wet (75°C) environments. Ideal for hazardous locations and demanding industrial installations.

Construction & Materials (Technical Correction Applied)

| Layer | Material Specification | Key Properties |

|---|---|---|

| Conductor | Bare copper (Class B/C stranding) | NEC-compliant sizing per ASTM B-8 |

| Insulation | XLPE or PVC (THHN/THWN equivalent) | 90°C dry / 75°C wet rating |

| Shielding | Optional per design | EMI/RFI protection |

| Overall Jacket | Heavy-duty PVC | Crush/impact resistant, sunlight resistant |

Correction Note:

-

Original text error: "THHN/THWN conductors" → Corrected to "insulated conductors with THHN/THWN equivalent performance"

-

Clarified insulation options: XLPE (XHHW), PVC (THHN), EPR, XLPO

Key Technical Specifications

| Parameter | Specification | Standard |

|---|---|---|

| Voltage Rating | 600V | UL 1277 |

| Temp. Rating | 90°C dry / 75°C wet | NEC 340 |

| Flame Test | VW-1 (FT1) | UL 1581 |

| Tray Fire Test | Passes 70,000 BTU IEEE-383 | IEEE 383 |

| Impact Resistance | ≥354 J (260 ft-lbf) | UL 1569 |

| Crush Resistance | ≥4,450 N (1,000 lbf) | UL 1277 |

| Sunlight Resistance | UV-resistant jacket | UL 1581 Sec 1200 |

Standard Configurations

| Conductor Size | Insul. Diameter (mm) | Overall Diameter (mm) | Weight (kg/km) |

|---|---|---|---|

| 2 AWG | 19.1 | 52.4 | 3137 |

| 1 AWG | 20.1 | 54.5 | 3506 |

| 1/0 AWG | 21.1 | 56.7 | 3943 |

| 2/0 AWG | 22.2 | 59.1 | 4470 |

| 3/0 AWG | 23.5 | 61.9 | 5196 |

| 4/0 AWG | 24.9 | 65.0 | 5996 |

| 250 kcmil | 26.4 | 68.0 | 6476 |

| 350 kcmil | 29.0 | 75.2 | 8795 |

| 500 kcmil | 32.2 | 82.2 | 11366 |

| 750 kcmil | 37.0 | 92.6 | 15677 |

(Grounding conductor included per NEC 250.122)

Critical Applications

-

Industrial Power Distribution:

-

Cable tray systems per NEC 318

-

Motor control centers

-

-

Hazardous Locations:

-

Class 1 Div 2 areas (NEC 501)

-

Petrochemical plants

-

-

Infrastructure:

-

Power generation facilities

-

Wastewater treatment plants

-

-

Installation Methods:

-

Cable trays, conduit, raceways

-

Direct burial (when listed)

-

Aerial with messenger support

-

Engineering Selection Guide

-

Insulation Selection:

-

XLPE (XHHW): Higher temp (90°C), better dielectric strength

-

PVC (THHN): Cost-effective for standard environments

-

-

Shielding Requirement:

-

Essential for VFD/motor circuits >100HP

-

-

Hazardous Area Compliance:

-

Verify Div 2 gap distances per NEC 501

-

-

Mechanical Protection:

-

Use impact-resistant variant for high-traffic areas

-

-

Bending Radius:

-

Minimum 20× overall diameter

-