Product Overview:

The SIHF Multi-Core Silicone Rubber Heating Cable delivers reliable freeze protection and process heating in extreme environments. Featuring a robust silicone rubber construction and wide temperature range (-60°C to +180°C continuous; +250°C peak), it’s engineered for dry, humid, wet, and outdoor installations with low mechanical stress. Compliant with key EU safety and material standards.

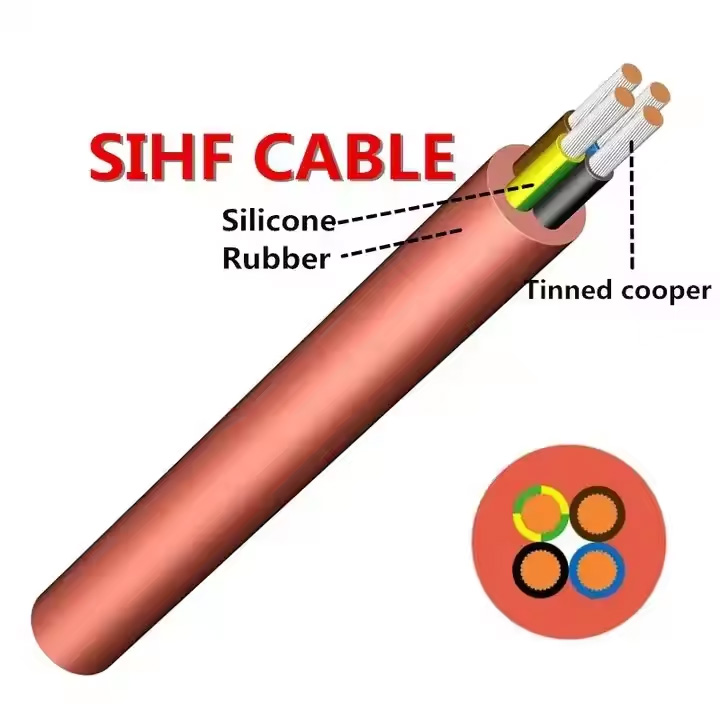

Construction:

The cable’s high-performance design comprises three critical layers:

-

Conductor:

Fine-stranded, tinned or bare copper wire (to DIN EN 60228 Class 5). Ensures flexibility and optimal conductivity. -

Insulation:

High-temp silicone rubber (Type 2GI1 per DIN VDE 0207-20). Provides electrical isolation and thermal stability. -

Outer Sheath:

Abrasion-resistant silicone rubber (Type 2GM1 per DIN VDE 0207-20), red-brown. Protects against moisture, chemicals, and mechanical stress.

Key Features & Benefits:

-

Extreme Temp Range: -60°C to +180°C (continuous) / +250°C (short-term)

-

Dual Silicone Protection: Insulation + sheath for maximum environmental resistance

-

Flame Retardant: Meets EN 60332-1-2 vertical flame test

-

Voltage Rating: 300/500V | Test Voltage: 2000V AC

-

Flexible Design: Class 5 stranded copper for tight bends

Standards Compliance:

-

Conductor: DIN EN 60228 (Class 5)

-

Materials: DIN VDE 0207 Part 20 (2GI1 insulation / 2GM1 sheath)

-

Core ID: HD 308 S2

-

Flammability: EN 60332-1-2

Typical Applications:

-

Pipe heat tracing (chemical, oil & gas)

-

Tank/vessel heating in humid/wet areas

-

Outdoor instrument freeze protection

-

De-icing for roofs, gutters, & machinery

-

Food processing line maintenance

Technical Specifications:

| Cores × Cross-Section (mm²) | Copper Weight (kg/km) | Conductor Construction | Overall Diameter (mm) | Cable Weight (kg/km) |

|---|---|---|---|---|

| 2 × 0.75 | 14.40 | 24 × 0.21 mm | 6.4 | 63 |

| 3 × 0.75 | 21.60 | 24 × 0.21 mm | 6.8 | 76 |

| 4 × 0.75 | 28.80 | 24 × 0.21 mm | 7.8 | 101 |

| 5 × 0.75 | 36.00 | 24 × 0.21 mm | 8.5 | 120 |

| 7 × 0.75 | 50.40 | 24 × 0.21 mm | 9.2 | 148 |

| 2 × 1.0 | 19.20 | 32 × 0.21 mm | 6.6 | 71 |

| 3 × 1.0 | 28.80 | 32 × 0.21 mm | 7.4 | 93 |

| 4 × 1.0 | 38.40 | 32 × 0.21 mm | 8.1 | 113 |

| 5 × 1.0 | 48.00 | 32 × 0.21 mm | 8.8 | 136 |

| 7 × 1.0 | 67.20 | 32 × 0.21 mm | 9.5 | 169 |

| 2 × 1.5 | 28.80 | 30 × 0.26 mm | 7.6 | 97 |

| 3 × 1.5 | 43.20 | 30 × 0.26 mm | 8.0 | 117 |

| 4 × 1.5 | 57.60 | 30 × 0.26 mm | 8.8 | 145 |

| 5 × 1.5 | 72.00 | 30 × 0.26 mm | 9.6 | 175 |

| 7 × 1.5 | 100.80 | 30 × 0.26 mm | 10.9 | 220 |

| 12 × 1.5 | 172.80 | 30 × 0.26 mm | 14.6 | 413 |

| 16 × 1.5 | 230.40 | 30 × 0.26 mm | 16.2 | 520 |

| 24 × 1.5 | 345.60 | 30 × 0.26 mm | 20.4 | 811 |

| 2 × 2.5 | 48.00 | 50 × 0.26 mm | 9.2 | 146 |

| 3 × 2.5 | 72.00 | 50 × 0.26 mm | 9.7 | 179 |

| 4 × 2.5 | 96.00 | 50 × 0.26 mm | 10.6 | 222 |

| 5 × 2.5 | 120.00 | 50 × 0.26 mm | 11.6 | 268 |

| 7 × 2.5 | 168.00 | 50 × 0.26 mm | 12.6 | 339 |

| 12 × 2.5 | 288.00 | 50 × 0.26 mm | 17.1 | 609 |

| 2 × 4.0 | 76.80 | 50 × 0.31 mm | 10.8 | 210 |

| 3 × 4.0 | 115.20 | 50 × 0.31 mm | 11.5 | 261 |

| 4 × 4.0 | 153.60 | 50 × 0.31 mm | 13.2 | 346 |

| 5 × 4.0 | 192.00 | 50 × 0.31 mm | 14.3 | 418 |

| 7 × 4.0 | 268.80 | 50 × 0.31 mm | 15.6 | 530 |

| 4 × 6.0 | 230.40 | 84 × 0.31 mm | 15.6 | 497 |

| 5 × 6.0 | 288.00 | 84 × 0.31 mm | 17.6 | 631 |

| 4 × 10.0 | 384.00 | 80 × 0.41 mm | 19.1 | 778 |

| 4 × 16.0 | 614.40 | 128 × 0.41 mm | 23.4 | 1,197 |

| 4 × 25.0 | 960.00 | 200 × 0.41 mm | 28.6 | 1,827 |

Note: Dimensions/weights approximate per manufacturing tolerances.

Engineering Guidelines:

-

Construction Advantage: Double-layer silicone (2GI1 + 2GM1) ensures durability in wet/high-heat environments.

-

Temp Limits: Continuous ≤180°C; ≤250°C (max 24h).

-

Bending Radius: ≥6 × cable diameter during installation.

-

Chemical Exposure: Verify silicone compatibility if used near aggressive fluids.

-

Identification: Red-brown sheath aids visual inspection.