![]()

Product Overview

Certified to DIN VDE 0250-1 and DIN EN 50525-2-83 standards, this dual-armored silicone cable combines fiberglass thermal protection with steel wire mechanical armor. Engineered for 180°C continuous operation in harsh industrial environments, its halogen-free construction ensures safety in critical power and control applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | AC 300/500V |

| Test Voltage | 2000V (core-core) / 4000V (breakdown) |

| Temp Range | -60°C to +180°C (fixed install) |

| +5°C to +180°C (flexible use) | |

| Conductor | Fine-stranded tinned copper |

| Insulation/Sheath | Silicone Rubber (Halogen-Free) |

| Armor Layers | Fiberglass + Galvanized Steel Braid |

| Bending Radius | 5×Ø (fixed) / 10×Ø (flexible) |

| Compliance | CE, RoHS, DIN VDE 0285-525-2-83 |

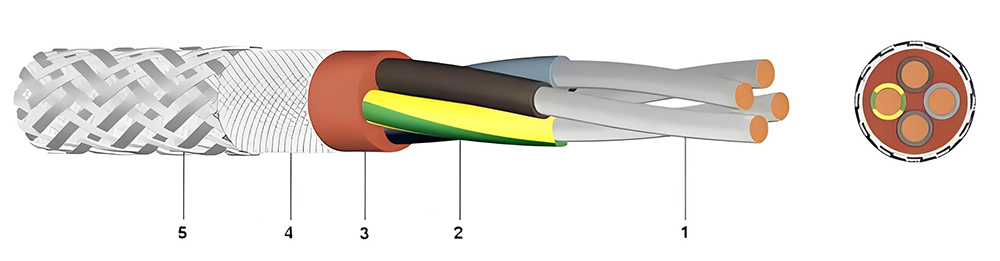

5-Layer Construction

-

Conductor:

-

Class 5 tinned copper strands (enhanced oxidation resistance)

-

-

Core Insulation:

-

Silicone rubber (VDE-certified 2GI1 grade)

-

-

Outer Sheath:

-

Silicone rubber (2GM1 grade, standard red-brown)

-

-

Primary Armor:

-

Woven fiberglass braid (thermal barrier)

-

-

Secondary Armor:

-

Galvanized steel wire braid (mechanical protection)

-

*Fig. 1: Dual-armor layer structure*

Performance Data (4-Core 16mm² Example)

| Property | Value | Test Standard |

|---|---|---|

| Conductor Resistance | ≤1.24 Ω/km (20°C) | IEC 60228 |

| Insulation Resistance | ≥20 MΩ·km | DIN VDE 0472 |

| Flame Retardancy | IEC 60332-1 Cat.A | |

| Steel Braid Coverage | ≥85% | DIN EN 50264 |

Critical Applications

-

Heavy Industrial: Cement kilns, steel mill furnace controls

-

Energy Sector: Power plant turbine wiring

-

Chemical Processing: Reactor instrumentation in corrosive zones

-

Material Handling: Port crane systems (wet/damp environments)

-

Infrastructure: Tunnel lighting, subway power feeds

Engineering Advantages

Safety & Compliance

-

Halogen-free construction prevents toxic fumes (IEC 60754-1)

-

Steel braid provides EMI/RFI shielding (30dB attenuation)

Durability

-

Withstands 15N/mm² crush force (DIN EN 50264-3-1)

-

Resists oils, acids, and UV exposure

Installation

-

50% higher flex cycles vs. single-armor cables

-

-60°C cold impact resistance (DIN EN 60811-504)

Ordering Information

| Core Config. | Size (mm²) | Armor Type | Standard Colors |

|---|---|---|---|

| 2/3/4/5-core | 1.5-95 | Steel + Fiberglass | Black, Grey |

| 3+1/4+1 | 4-70 | Custom Options | RAL-coded |

Example: SiHF/GL-P-4G16 = 4-core 16mm² with dual armor